A team of researchers recently explored the active properties of starch films, particularly in terms of their physical, mechanical, and antibacterial properties, in order to demonstrate their applications in food packaging. This work is published in the open-access journal, Polymers.

Study: Physical, Mechanical, and Water Vapor Barrier Properties of Starch/Cellulose Nanofiber/Thymol Bionanocomposite Films. Image Credit: Marlon Trottman/Shutterstock.com

Plastics vs Biopolymers in Food Packaging

Although petroleum-based plastics are used in food packaging owing to their beneficial physicochemical and processing properties, they are non-degradable, hard to recycle and cause massive plastic pollution. The negative environmental impact of these products has triggered more interest in developing bio-based polymers or biopolymers for use as biodegradable films in food packaging.

Although starch is a promising biopolymer for biodegradable films and it is abundant and economical, the application of starch films in food packaging materials is limited due to its poor mechanical and barrier properties. However, studies have shown that the addition of cellulose nanofibers (CNF) and thymol as reinforcing agents improve the properties of starch films.

Incorporating nanosized fillers and antimicrobial and/or antioxidants agents into the starch films helps improve the granular structure as well as the functional properties of starch films. The addition of nano-sized fillers in starch films to form bionanocomposites has been shown to improve the thermal, mechanical, and barrier properties of the starch films.

Due to the similarities in the chemical structure between CNF and starch matrix, there is good adhesion between the two components in starch-based films, which facilitates bonding and boosts the thermal, mechanical, and barrier properties.

Image Credit: Othman SH et al., Polymers

About the Study

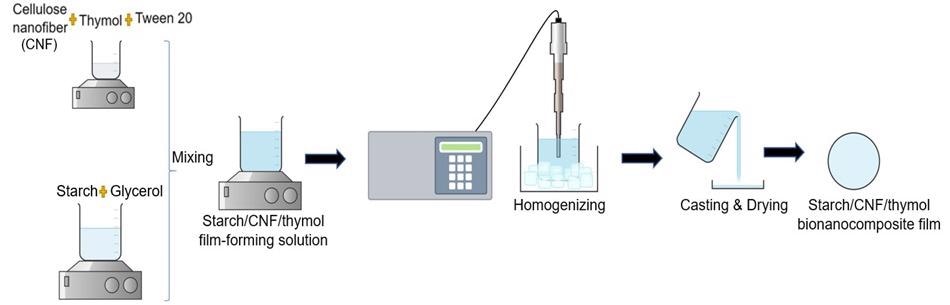

The authors investigated the effects of adding different concentrations of thymol (3, 5, 7, and 10 wt.%) on the mechanical, physical, water vapor barrier, and antibacterial properties of corn starch films, with 1.5 wt.% CNF synthesized using the solvent casting method. They modified the solvent casting method to obtain a more homogenous starch/CNF/thymol film-forming solution and improve the properties of the films.

Higher amounts of CNF reduced the water vapor permeability and mechanical strength of the films. Since thymol is volatile, the temperature was fixed at 50°C to minimize the loss of thymol during the synthesis.

The physical properties of the films such as color, thickness, opacity, and appearance were determined. A digital micrometer was used to measure the thickness of the films and a color spectrophotometer determined the color of the films. The water vapor barrier was determined using a dry cup method based on ASTM E96 to establish the water vapor permeability (WVP) of the films.

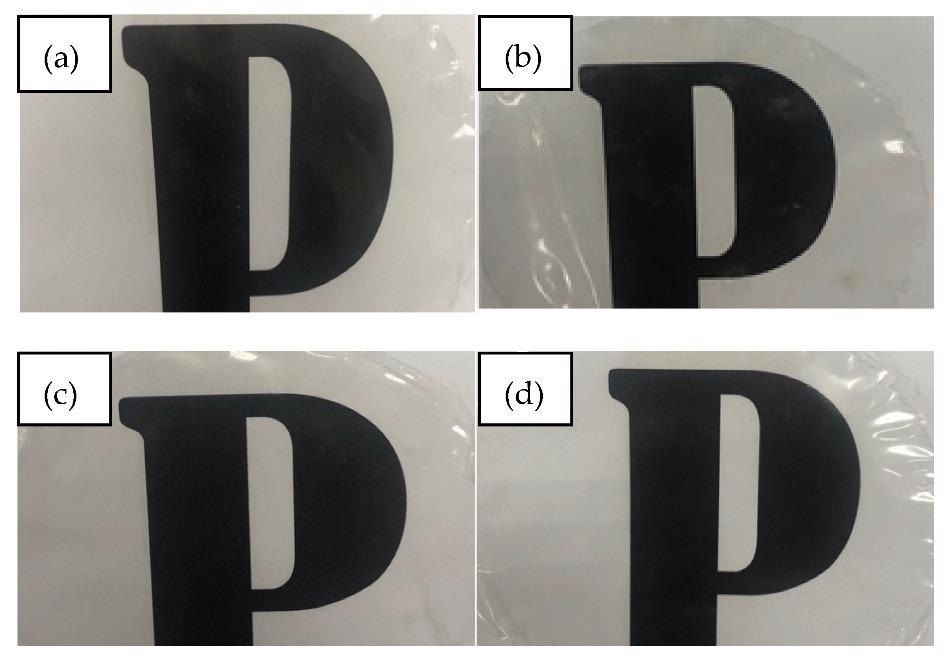

Physical appearance of starch/CNF bionanocornposite films incorporated with (a) 0, (b) 3, (c) 5, and (d) 10 wt % of thymol. Image Credit: Othman SH et al., Polymers

What were the Observations of the Study?

The results showed that the addition of thymol did not have a significant impact on the color and opacity of the starch films. Low opacity value shows high transparency of the film, which is an important factor in food packaging materials that helps track the product quality during distribution and storage.

The modifications made by the authors in the preparation of the CNF/thymol emulsion to produce a more homogenous starch/CNF/thymol film-forming solution improved the appearance and transparency of the films.

The researchers observed a slight increase in the thickness of the starch/CNF bionanocomposite films proportional to the addition of increasing concentrations of thymol. This was attributed to the plasticizing effect of thymol, due to which the intermolecular biopolymer chains restructure, causing voids that lead to thicker films.

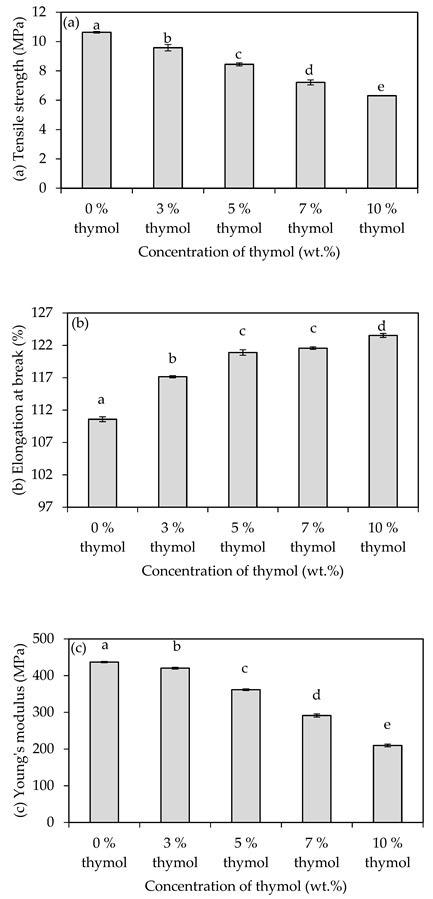

The tensile strength (TS) and Young’s modulus (YM) of the films were found to decrease from 10.6 to 6.3 MPa and from 436.9 to 209.8 MPa, respectively. Also, the elongation at the break of the films increased from 110.6% to 123.5% with the addition of 10 wt.% thymol. Moreover, adding higher concentrations of thymol (7 and 10 wt.%) was shown to improve the water vapor barrier of the starch films by approximately 60.0%, from 4.98 × 10—9 to 2.01 × 10—9 g/d.m.Pa.

With the addition of 5 wt.% and higher concentrations of thymol, the inhibition zone against E. coli was observed in the films with the inhibition zone’s diameter increasing with the increase in thymol concentration. Using in vivo analysis, the researchers demonstrated that the starch/CNF/thymol-10 wt.% bionanocomposite film can inhibit microbial growth and decrease the bacterial count on the fresh meat samples.

(a) Tensile strength, (b) elongation at break, and (c) Young's modulus of starch/CNF bionanocompostte films incorporated with different concentrations of thymol. Different letters in the same graph indicate a statistically significant difference (p < 0.05). Image Credit: Othman SH et al., Polymers

Conclusions

To summarize, this work incorporated different concentrations of thymol into starch/CNF bionanocomposite films and investigated the results. The findings show a slight increase in thickness and opacity of the films and in terms of mechanical properties, a decrease in TS and YM, and an increase in EAB with the increase in thymol concentrations. This indicates the decrease in rigidity and improvement in flexibility of the films due to thymol’s plasticizing effect.

The mechanical properties of the starch/CNF/thymol bionanocomposite films prepared by the researchers were similar to that of some commonly used food plastic materials, which confirms the suitability and high potential of these films for flexible food packaging applications. Starch/CNF/thymol bionanocomposite films also exhibited antibacterial activity against E Coli. In conclusion, the starch/CNF/thymol bionanocomposite films produced in this study are suitable for use as flexible, antibacterial food packaging materials. Future studies can focus on the biodegradability and thermal properties of these films, as they are crucial factors for food packaging applications.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Othman SH, Wane BM, Nordin N, Noor Hasnan NZ, A. Talib R, Karyadi JNW. Physical, Mechanical, and Water Vapor Barrier Properties of Starch/Cellulose Nanofiber/Thymol Bionanocomposite Films. Polymers. 2021; 13(23):4060: https://www.mdpi.com/2073-4360/13/23/4060