Writing in the journal Polymers, a team of scientists has published research into the hydrolysis behavior and physiochemical properties of cellulose samples of microbial, vegetal, and synthetic origin.

Study: Properties and Hydrolysis Behavior of Celluloses of Different Origin. Image Credit: TinyPhoto/Shutterstock.com

Cellulose: A Commercially Important Biomaterial

Cellulose is produced primarily by plants, where it is the major polysaccharide component of cell walls. This biomaterial is bound to other polymeric components of the complex composite matrix, which are hemicellulose and lignin. The chemical composition of plant cell walls varies according to plant species, age, environmental factors, and so forth.

Besides plants, cellulose is synthesized by several microbial species, with bacterial cellulose extensively studied in research. Bacterial cellulose has proven to be an attractive biomaterial for several commercial applications, such as biomedical devices, tissue engineering, food products, environmental applications, and opto- and bio-electronic devices.

The potential commercial applications of cellulose are constantly expanding due to the development of composite materials and the introduction of novel and innovative technologies such as additive manufacturing. Aside from vegetal and microbial sources, there has been intense research into the development of synthetic cellulose in recent years. Whilst these types of cellulose are less common, they provide benefits such as tunable and controllable final cellulose structures.

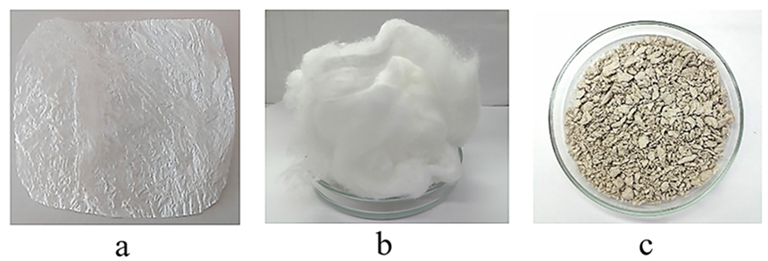

Photographs of cellulose samples: (a) BC, (b) synthetic cellulose and (c) Miscanthus-derived cellulose. Image Credit: Kashcheyeva, E.I et al., Polymers

Enzymatic Hydrolysis and Cellulose

The specific structure and properties of cellulose differ according to their origin, but one of the fundamental properties of cellulose is its degradability by enzymatic hydrolysis. This sophisticated catalytic process is influenced by several factors, including the physical and chemical structure of cellulose itself.

Whilst it was believed for a long time by researchers that the process and its factors were well-established, in recent years, research has revealed new and surprising insights that present several challenges for scientists in multiple application fields. Studies have demonstrated mixed results due to the complexity of substrates being studied.

The Study

To address the complex issues that researchers in fields that utilize cellulosic biomaterials and composites face currently, the new paper in Polymers has investigated the physiochemical properties and enzymatic hydrolysis behavior of cellulose of bacterial, vegetal, and synthetic origin.

Different cellulose samples were sourced from various organizations and companies. For the bacterial sample, the biomaterial was produced using M. gisevii Sa-12, and an enzymatic hydrolysate obtained from oat hull pulp was used to synthesize bacterial cellulose. The produced bacterial cellulose pellicle was air-dried and then subjected to enzymatic hydrolysis and analysis.

Vegetal cellulose samples were isolated from M. sacchariflorus, which is a fast-growing perennial cereal crop that contains 45-54% cellulose. Synthetic cellulose was produced via electropolymerization of aqueous glucose solutions.

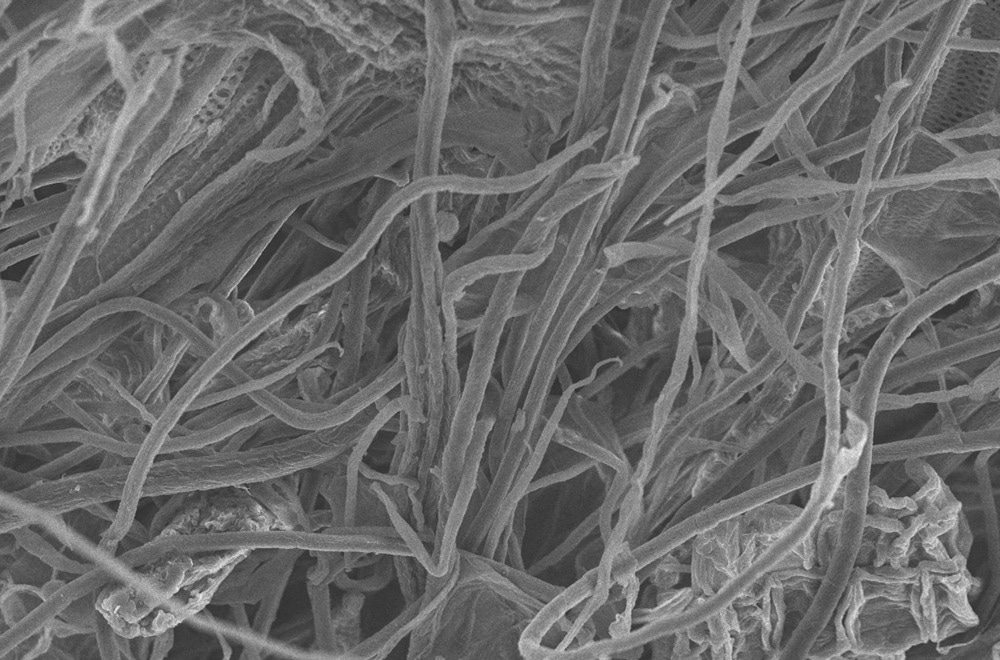

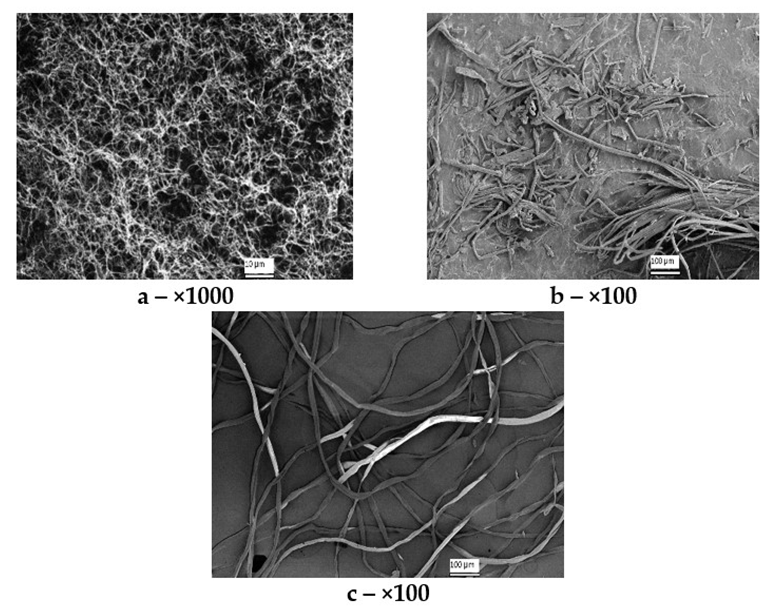

SEM images of cellulose samples of different origin: (a) BC, (b) synthetic cellulose, and (c) Miscanthus cellulose. Image Credit: Kashcheyeva, E.I et al., Polymers

Samples were analyzed using several methods. Polymerization degree and chemical composition (cellulose, lignin, pentosan, and ash) were determined using standard chemical and physiochemical methods. X-ray diffraction, IR spectroscopy, scanning electron microscopy analysis, and categorization of pore volume and specific surface were conducted.

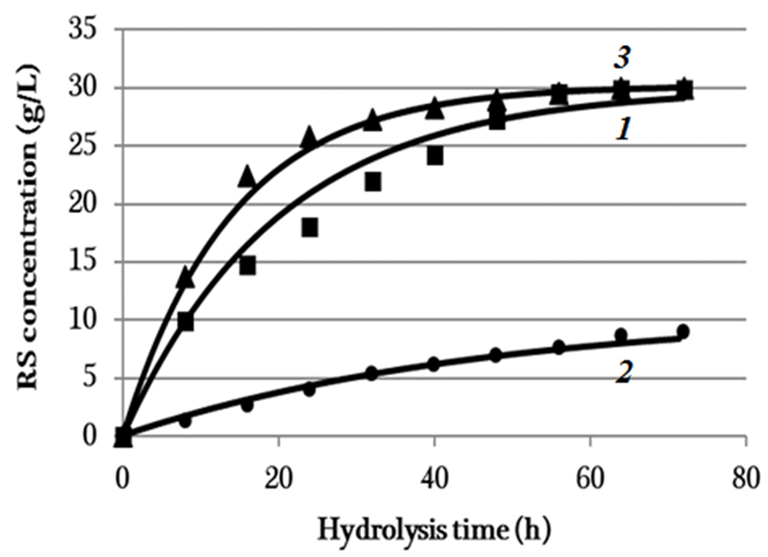

A cocktail of commercially available enzymes was utilized to evaluate the enzymatic hydrolysis of the different samples. The cocktail was composed of Ultraflo Core and CelloLux-A. A 0.1 M acetate buffer was used to conduct the enzymatic hydrolysis, which has a mildly acidic pH of 4.7. Hydrolysis was carried out at 46 ± 2 °C and with a reaction time of seventy-two hours. Reducing sugar content was evaluated every 8 hours.

Study Findings

The authors unveiled the influence of cellulose type on hydrolysis behavior in the study, which addresses a significant research question. It was demonstrated in the research that factors such as substrate morphology, crystallinity degree, and polymerization degree have a significant influence on the enzymatic hydrolysis of plant and synthetic celluloses.

Enzymatic hydrolysis of synthetic cellulose with high degrees of polymerization and crystallinity and a compact structure has a 27% efficiency, whereas bacterial cellulose has the highest hydrolysis rate, with a final reducing sugar yield of 90% observed by the researchers. Properties such as pore volume, specific surface, and the absence or presence of impurities have a negligible influence on bioconversion.

Cellulose derived from M. sacchariflorus has a surface morphology that is highly accessible to enzymes, which helps explain why the bioconversion rate for this type of cellulose is the highest observed in the study. One of the key factors, therefore, that influences hydrolysis behavior is the cellulose’s nanoscale network structure which enhances the ability of enzymes to penetrate the biomaterial.

The RS concentration plotted against the enzymatic hydrolysis time of cellulose samples and graphically interpreted experimental data processing results (1) BC, (2) synthetic cellulose, and (3) Miscanthus cellulose. The half-width of the confidence interval for RS concertation was ±0.2 g/L. Image Credit: Kashcheyeva, E.I et al., Polymers

In Conclusion

The paper has provided key information on how cellulose sources influence enzymatic hydrolysis behavior, which has important implications for the commercial use of this biomaterial in several industries. Further research is needed to properly discriminate between the various factors which influence cellulose synthesis, and the authors plan to further study the factors specific to synthetic cellulose synthesis.

More from AZoM: What is the Function of Isotopic Analysis?

Further Reading

Kashcheyeva, E.I et al. (2022) Properties and Hydrolysis Behavior of Celluloses of Different Origin Polymers 14(18) 3899 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/18/3899

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.