With the push to net-zero by 2050 gathering pace, renewable fuels are being explored and developed to phase out petrochemical fuels. Biofuels are gaining attention as a viable fuel type for heavy industry and the transportation sectors, and research has focused on the manufacture of these fuel types. A study published online in Frontiers in Energy Research has explored their production from a techno-economic viewpoint.

Study: Techno-Economic Analysis of a Flexible Process Concept for the Production of Transport Fuels and Heat from Biomass and Renewable Electricity. Image Credit: JH Bispo/Shutterstock.com

The Push for Renewable Energy and Fuels to Achieve Net Zero

The world is warming due to human activities, facilitating the need to drastically reduce carbon emissions. Various alternative fuels and power sources have been investigated to meet the energy demands of society, including hydrogen, solid-state batteries, and biofuels. Biofuels have proven to be especially attractive as an alternative to petrochemical-derived petrol and diesel.

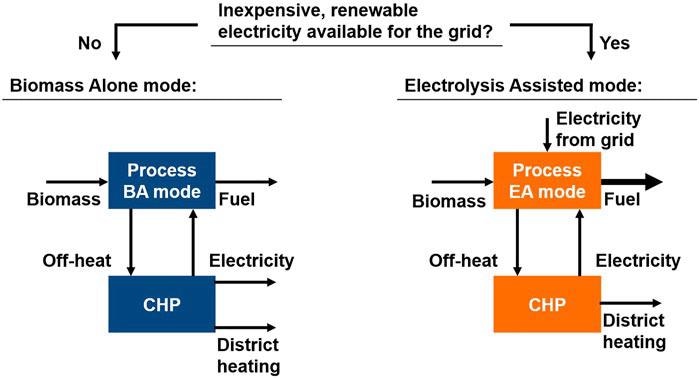

Operation modes for the hybrid process concept. Image Credit: Habermeyer, F et al., Frontiers in Energy Research

In line with the European Union’s Green Deal, significant work is being undertaken to increase the proportion of energy from renewable sources in the total energy mix to 65% by 2030. Currently, the proportion of renewable energy stands at 32%, which means that this figure will have to double over the course of this decade.

This presents significant technical and economic challenges for the energy sector in the European Union. Short-term mismatches in supply and demand need to be addressed. Studies have shown that an approach that utilizes a combination of energy storage and flexible demand strategies will be required to achieve an efficient energy transition from fossil fuels to renewables.

The transportation sector is a major emitter of greenhouse gas emissions. Electrification is only one part of the plan to decarbonize the transport sector as the power demands of aviation and heavy transport such as shipping, trains, and haulage still demand liquid fuels with high energy density. Therefore, low-carbon and renewable fuel alternatives and associated technologies need increased focus and deployment by 2030.

Additionally, biomass-fuelled heating and power stations need to be developed to fill the energy gap left by phasing out fossil fuels. Whilst renewables like wind and solar will provide a sizeable proportion of renewable energy generation solutions, there is still a place for biomass-powered energy generation.

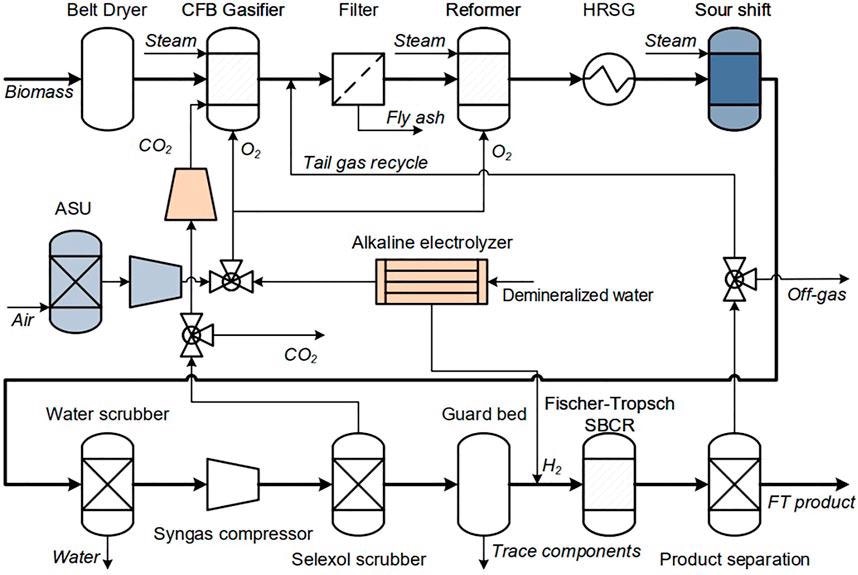

Process flowsheet–blue signifies equipment only operated during BA mode, orange during EA mode. Image Credit: Habermeyer, F et al., Frontiers in Energy Research

Processes for Producing Fuel from Biomass: BtL and PBtL

Two processes for producing renewable fuels have been thoroughly investigated in recent years. These are known as the Biomass to Liquid Fuel (BtL) and the Power and Biomass to Fuel (PBtL) processes. BtL converts biomass to hydrocarbon chains that can be used to manufacture renewable fuel via the Fischer-Trope route. PBtL differs from this process by incorporating electrolytic hydrogen into the BtL process. PBtL has higher levels of carbon efficiency compared to BtL.

Biomass to liquid fuel processes has been explored from a techno-economic standpoint in several studies that have demonstrated its economic potential. The realistic production cost of this process ranges from 1-4 euros per liter for a four hundred MWth plant, with the process displaying increasing maturity. Currently, demo plants are waiting to enter operation until the promotion of sustainable fuels reaches a point where they can be commercially implemented.

Power and Biomass to Liquid Fuel has an economic edge over BtL when cheap renewable power is available. The addition of renewable energy to the biomass conversion process increases the yield of fuel, driving down the cost of production.

Techno-Economic Analysis of a Hybrid Model

The study published in Frontiers in Energy Research has taken the previously published literature on renewable fuel research and development and the techno-economic analyses in the field and presented a hybrid model. A techno-economic analysis was carried out on the commercial viability of the hybrid model.

The hybrid model can switch between biomass-only processes and electrolysis-enhanced conversion operational modes depending on demands. Previous studies have demonstrated the feasibility of a hybrid process, with Müller et al. demonstrating the use of hydrogen generated by a wind park integrated into an FT-BtL process.

Hybrid systems have a higher initial investment cost, but the advantage of these systems lies in their reduced operational costs. They can produce fuel at lower cost and biomass consumption levels than a standalone BtL process. An additional economic advantage is the ability to shut down the electrolyzer temporarily to avoid high electricity prices in a fluctuating market.

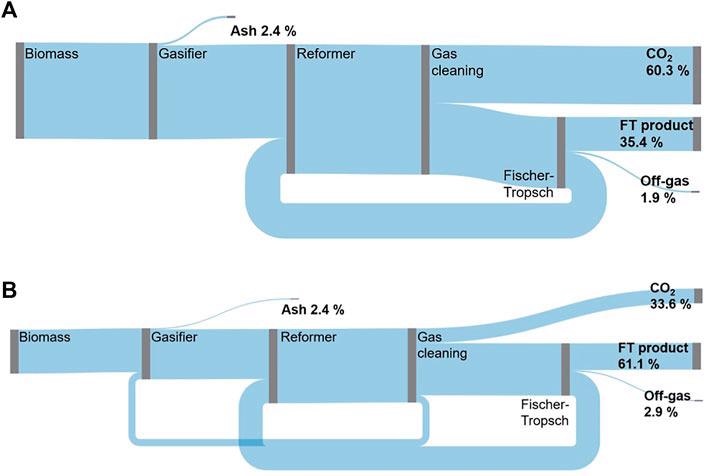

Carbon flow Sankey diagram for case 1.1 BA mode (A), EA mode (B). Image Credit: Habermeyer, F et al., Frontiers in Energy Research

The hybrid process showed an overall 53.3% carbon efficiency rate compared to 61.1% for PBtL and 35.4% for BtL models. Production costs for the hybrid model were found to be 1.08 €2019/L. Net production costs could be lowered by 0.07€.

Although the study found that the most economically viable process due to current renewable electricity prices was BtL, changing market forces like the cost of power and biomass, technological advances, and trends toward cheaper electrolyzers could make the hybrid model economically feasible in the future. More studies will be needed in the future into the processes to realize their full potential to move the world toward net-zero by 2050.

Further Reading

Habermeyer, F et al. (2021) Techno-Economic Analysis of a Flexible Process Concept for the Production of Transport Fuels and Heat from Biomass and Renewable Electricity [online] Front. Energy Res. | frontiersin.org. Available at: https://www.frontiersin.org/articles/10.3389/fenrg.2021.723774/full

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.