Additive manufacturing or 3D printing is a well-established technique for fabricating various designs and forms of complex shape or intricate detail. The method is also relatively common for printing mammalian cells for tissue engineering and has more recently been used to print microbial cells for biomedical and biotechnological applications.

Image Credit: Duraj-Thatte, A. and Manjula-Basavanna, A., et al., (2021) Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers. Nature Communications, [online] 12(1). Available at: https://doi.org/10.1038/s41467-021-26791-x

Image Credit: Duraj-Thatte, A. and Manjula-Basavanna, A., et al., (2021) Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers. Nature Communications, [online] 12(1). Available at: https://doi.org/10.1038/s41467-021-26791-x

The ability to produce a bioink that can be used in 3D printing applications could usher in a wave of exciting opportunities, such as being used in novel biomedical applications to release drugs, remove toxins from the air, and regulate its own growth.

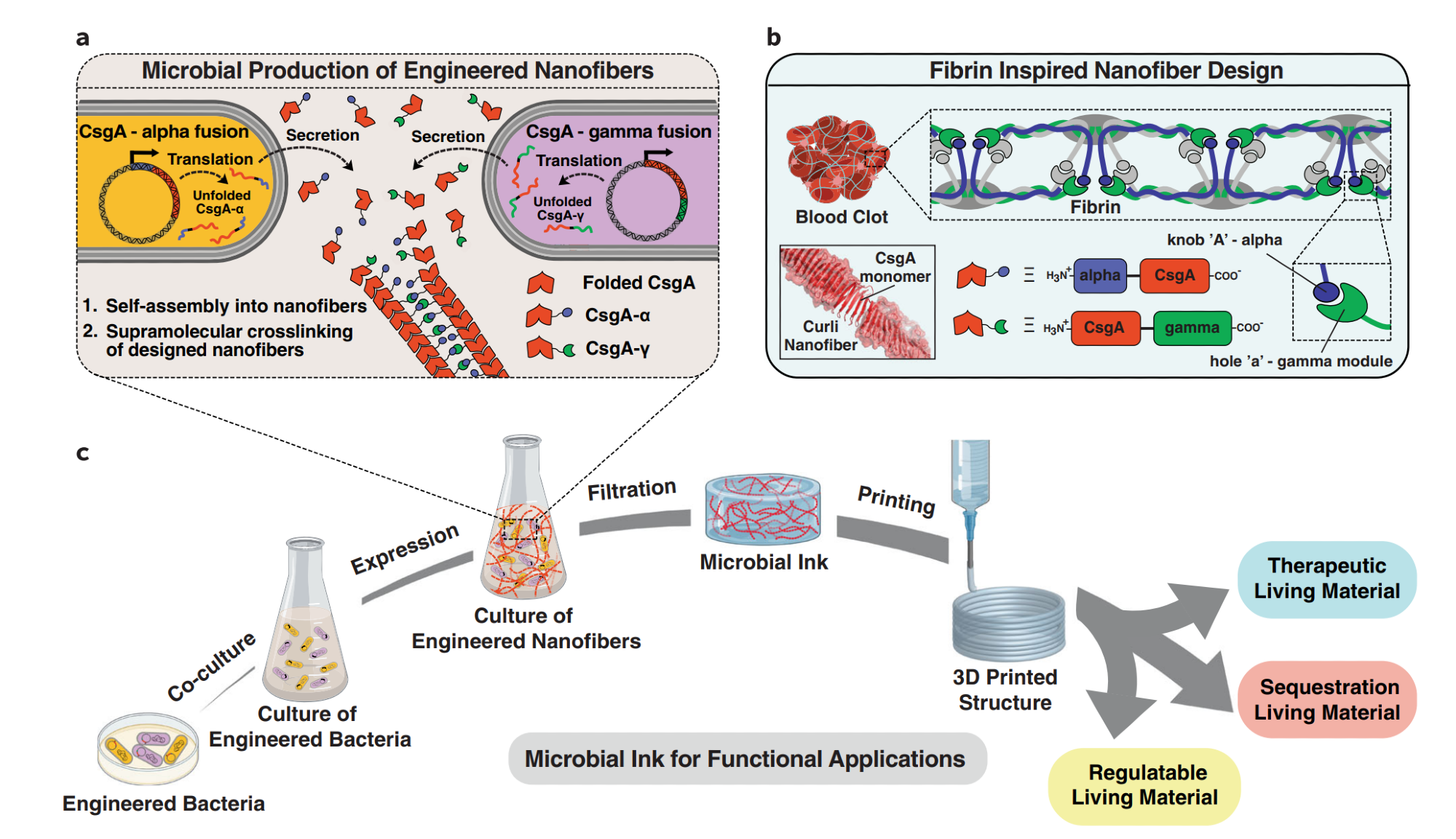

Now, a team of Harvard-based researchers has developed a new strategy for tackling such problems — engineering Escherichia coli to create a bio-ink for use in a 3D printer. The research, published in Nature Communications, details the method of design and potential applications for the bioink created using genetically engineered microbial cells.

For a number of years, microbial engineers have been working on designing a system that can create living materials for use in a wide range of applications, such as in medical devices.

However, it can be a major challenge when trying to get bio-materials to conform to complex 3D structures, often proving to be a daunting task.

Genetically Programmed Bioinks

Overcoming the challenge and designing a successful bio-ink that could be 3D printed demanded outside-of-the-box thinking. To do this, the researchers needed to come up with something that mimics the properties of toothpaste; firm enough to hold its shape when resting but will flow like a liquid when under pressure.

Accordingly, the 3D printer applies pressure to the ink to squeeze it through the nozzle, but once the ink is set in position, it will form a gel-like substance that can support itself: “A printable bioink requires a viscosity low enough to facilitate extrusion, but high enough to retain its shape after printing.”

In this regard, shear-thinning hydrogels, which decrease their viscosity with increasing shear stress, are an attractive option.

Neel Joshi, Co-Author and Associate Professor at School of Engineering and Applied Sciences, Harvard University

The work began by bioengineering the bacteria to produce living nanofibers. The researchers then grouped the fibers and added other ingredients to produce a kind of living ink that could be used in a traditional 3D printer.

Once the team had found a workable solution, they began to bioengineer other microbes to fabricate other types of living fibers or materials and introduced them to the ink. They then used the ink to print 3D objects that had a variety of living components.

One of the materials secreted azurin – an anticancer drug – when stimulated by specific chemicals. The other was a material that isolated Bisphenol (a known environmental toxin) without help from other chemicals or devices.

By embedding genetically programmed E. coli cells in the microbial ink, we demonstrate the 3D printing of therapeutic living material, sequestration living material, and regulatable living material.

Neel Joshi, Co-Author and Associate Professor at School of Engineering and Applied Sciences, Harvard University

Otherworldly Applications

The microbial ink design can be tailored and modified further for different biotechnological and biomedical applications, utilizing the ever-growing toolset of biological parts that are being developed by synthetic biologists.

What’s more, the microbial bioink developed by the Harvard researchers could also have otherworldly applications. For instance, it could be used to build structures in space or extraterrestrial habitats where raw material transport is difficult, making on-demand, in-situ fabrication of building materials from extremely limited resources essential.

In effect, astronauts could take the microbial bioinks with them and use them to 3D print the various materials and structures for their project. This is due to the fact the microbes used in the study demonstrated the capacity to independently make the bioink in which the living cells are encapsulated.

References and Further Reading

Duraj-Thatte, A. and Manjula-Basavanna, A., et al., (2021) Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers. Nature Communications, [online] 12(1). Available at: https://www.nature.com/articles/s41467-021-26791-x

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.