In a recent study published in the journal Fuel, researchers from Spain developed a novel family of reduced graphene ZnO-NiO sorbents produced by less costly and easily reproducible methods.

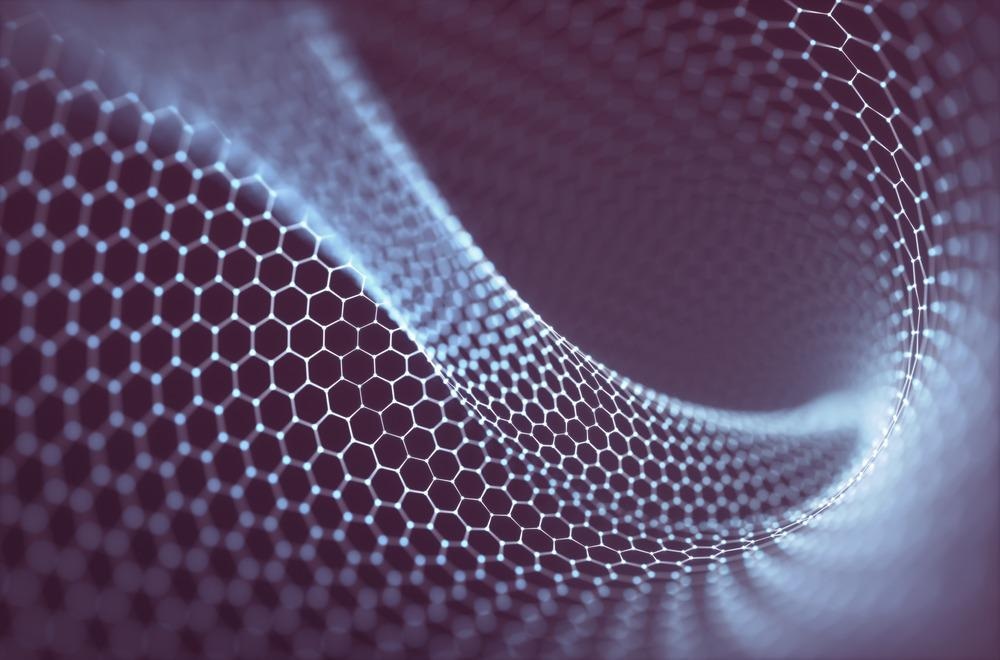

Study: Novel ZnO-NiO-graphene-based sorbents for removal of hydrogen sulfide at intermediate temperature.Image Credit: ktsdesign/Shutterstock.com

Hydrogen Sulfide Removal and Graphene

The main driver of a renewed surge in comprehensive sulfur removal is the prevention of poisoning of sulfur-sensitive catalysts during the up-gradation of syngas to biofuel. Technologies dependent on regenerable sorbents in the 300 ◦C –500 ◦C (intermediate temperature) range are used for improved process integration.

Graphene is an allotrope of carbon with excellent properties such as intrinsic strength, high specific surface, excellent mechanical properties, thermal conductivity, and electrical conductivity. Out of different forms of graphene, rGO (reduced graphene oxide) has advantages such as bulk quantity production and low cost. The high affinity of graphene for H2S makes it a potential adsorbent for separating H2S as the sulfur atoms can get bonded to graphene.

The researchers investigated hydrogen sulfide removal at intermediate temperature by applying zinc oxide sorbents supported on graphene. Hence, a new family of reduced graphene ZnO-NiO sorbents (Zn-Ni-rGO) was developed by researchers, and a preliminary study was conducted to assess its potential use for hydrogen sulfide removal at intermediate temperature.

Methodology

The synthesis of the new sorbent family (Zn-Ni-rGO) involved two steps - synthesis of graphite oxide and synthesis of ZnO- NiO-rGO sorbents. Graphite oxide was synthesized by the oxidation of graphite using two different methods – the improved Tour method (GrO-T) and the conventional Hummers method (GrO-H).

Five mg.mL− 1 homogeneous GO dispersions (total volume: 120 mL of both GrO-H and GrO-T) were prepared, followed by a sonication bath (using low power and probe sonication) for one hour. Samples containing different quantities of Zn(NO3).6H2O (99% pure), Ni(NO3).6H2O (99% pure), and urea were successively added to the GO dispersions.

It was followed by the hydrothermal method, which involved treatment in polytetrafluoroethylene lined (PTFE)-lined stainless steel autoclaves at 120 ◦C for 24 hours, two times washing with ultrapure water, drying at 60 ◦C under vacuum, and thermally annealing to obtain the Zn-Ni-rGO.

Results

The commercial ZnO-NiO sorbents (Z-SorbTM) and the synthesized novel Zn-Ni-graphene sorbents (rGO-NiO-ZnO) were studied at the post-reaction stage and characterized by XRD (X-ray diffraction), N2 adsorption, and XRF (X-ray fluorescence).

Further Reading: Using Graphene to Purify Seawater

Post synthesis, the total concentration of the elements present in each sample was determined by XRF analysis which showed that the novel Zn-Ni-graphene sorbents were efficient at intermediate temperatures.

The sulfidation tests indicated that desulfurization occurred by selective adsorptive reaction of hydrogen sulfide with ZnO and NiO to yield the corresponding sulfides, which was confirmed by the analysis of post-reaction samples. Further, Z-SorbTM and Zn-Ni-rGO samples were analyzed in a fixed bed reaction system developed by the researchers employing XRF and XRD to determine the nature of the sulfur species developed during the reactive adsorption sulfidation.

The sulfur content (ranging from 20 to 28 wt%) was higher than the sulfur content in the ZsorbTM sample. The results indicate a higher adsorption capacity compared to the commercial adsorbent. Porosity due to the interaction between Ni and Zn oxides, the oxygen groups attached to the graphene layers, and the formation of more active sites are probable reasons for the enhanced adsorption capacity.

Conclusions

In this study, new sorbents based on ZnO-NiO on reduced graphene (Zn-Ni-rGO) were synthesized by the researchers to remove hydrogen sulfide at intermediate temperature, and their performance was assessed.

The use of the improved Tour method (GrO-T) and the conventional Hummers method (GrO-H) produced stable precursors that were able to support the active types for hydrogen sulfide sorption (ZnO and NiO). The successive addition of Ni(NO3), Zn(NO3), and GO followed by reduction and annealing produced a suitable sorbent.

Full removal of H2S was possible at the process conditions employed by the researchers. Desulfurization occurred by selective adsorptive reaction of hydrogen sulfide with ZnO and NiO, which was further confirmed in the post-reaction stage.

The performance of all graphene-based sorbents developed by the researchers was better than the commercial reference material used in the study. The new family of reduced graphene ZnO-NiO sorbents, Zn-Ni-rGO synthesized by the researchers is a potential candidate for syngas cleaning and is produced using cost-effective and easily replicable methods.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Novel ZnO-NiO-graphene-based sorbents for removal of hydrogen sulfide at intermediate temperature. J.M. Sánchez-Hervás, M. Maroño, R. Fernández-Martínez, I. Ortiz, R. Ortiz, M.B. Gómez-Mancebo. Fuel. 2021, 122724. https://www.sciencedirect.com/science/article/pii/S0016236121025898