A paper published in the journal eScience has explored the potential of electrospinning as a method for tailoring the structure of silicon-based anode materials and improving the properties of batteries that make use of them.

Study: Tailoring the structure of silicon-based materials for lithium-ion batteries via electrospinning technology. Image Credit: MAOIKO/Shutterstock.com

Silicon has emerged as a forerunner in research into anode materials for next-generation lithium-ion batteries. However, there are challenges with the material which hinder its commercial application.

Silicon-Based Anode Materials in Lithium-Battery Design

The demand for lithium-ion batteries is increasing due to the rapid electrification of multiple sectors of industry and the need to phase out fossil fuels to avert the climate crisis. The power demands for renewable energy, consumer electronics, and electric vehicles have all driven advances in battery design and deployment.

The demand for low-cost, high-energy-density batteries is increasing globally. This has facilitated the development of new materials for lithium-ion battery components such as cathodes and anodes. Traditional, commercially available materials are insufficient for next-generation applications due to their relatively low specific capacity.

Silicon has emerged as a candidate for next-generation lithium-ion battery anodes. Advantageous properties of silicon-based materials include high theoretical volumetric and gravimetric capacity. Additionally, silicon has a low lithiation potential. Moreover, it is an extremely abundant material in the Earth’s crust. Advances in the semiconductor industry have facilitated the conditions for producing and preparing silicon-based materials.

Illustration of effective structural design strategies to solve current issues of Si-based anode materials for LIBs. Image Credit: Huang, A et al., eScience

However, despite their advantageous properties, silicon-based anodes have severe shortcomings that hinder their commercial viability. They possess low electrical conductivity and undergo significant volume variation during device operation.

During the lithium-ion insertion and extraction process, the volume of silicon anodes can change by up to 400%. During delithiation, the anodes shrink. This volumetric change leads to serious capacity decay issues and destroys the electrode structure.

Ultimately, this causes a huge consumption of lithium ions and electrolytes, severely impacting the lifespan, reliability, and electrochemical properties of lithium-ion batteries. Enhanced electrode degradation and low Coulombic efficiency are two results of this.

Addressing the Challenges with Silicon Anodes

In order to address these challenges and overcome the limitations of silicon-based anodes, numerous studies have concentrated on enhancing materials with various structures. These include nanoparticles, nanocrystals, nanosheets, nanopores, nanospheres, nanomembranes, and nanotubes. Strain relaxation is facilitated by the rapid transport of lithium ions in the nanomaterials. Amongst these materials, 1D nanomaterials have shown promise for silicon-based lithium-ion battery anodes.

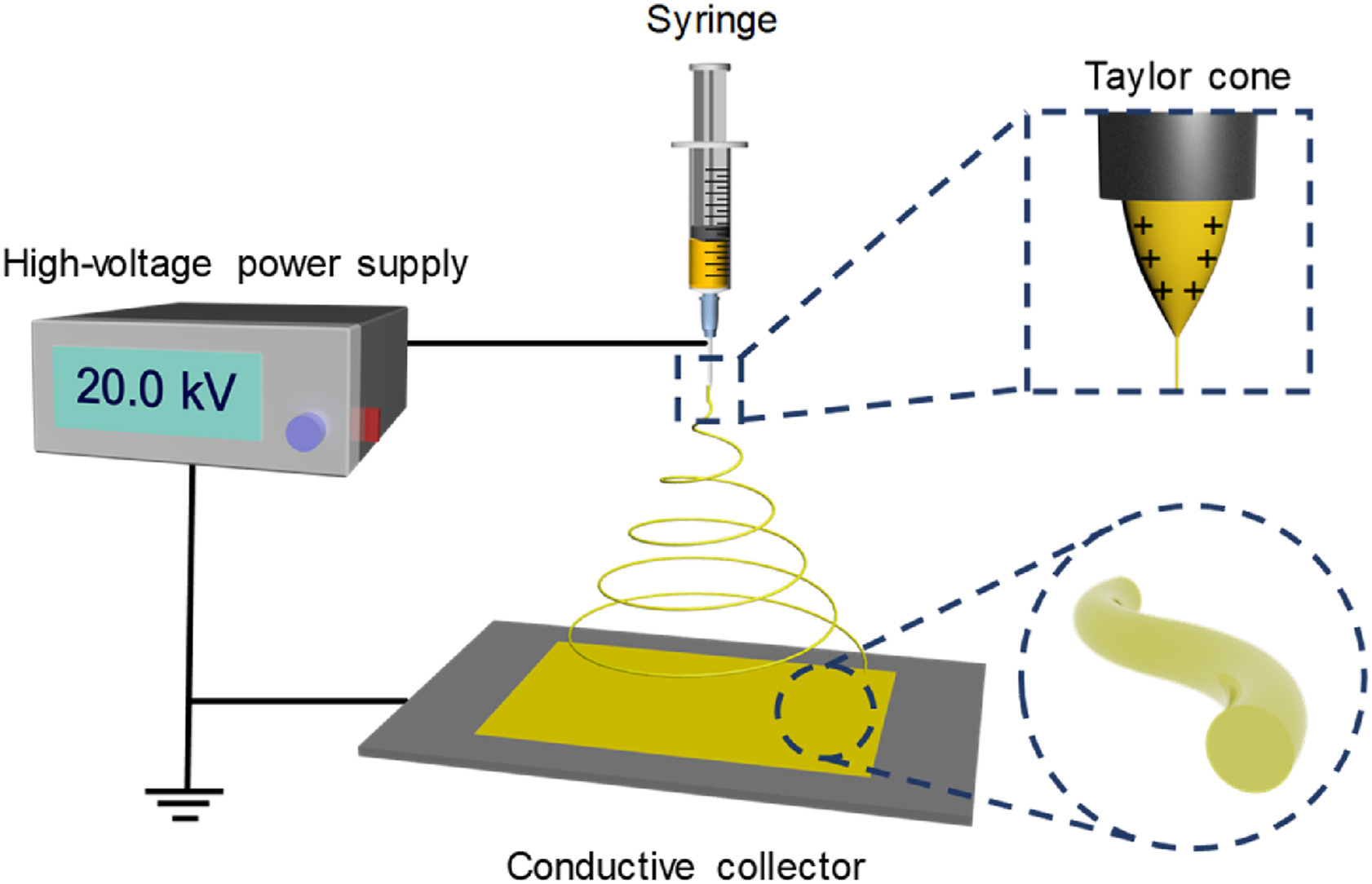

There are many methods that can be used to fabricate 1D nanomaterials, including chemical etching, electrospinning, and chemical deposition. Of these strategies, electrospinning has proven to be particularly attractive due to its efficiency, simplicity, and ease of mass production for preparing 1D nanofibers. The technique is used in several industries such as energy, environmental protection, and biomedicine.

The electrospinning process can be adjusted by changing its parameters. This facilitates the possibility of tailoring structures produced by the process. Structures with unique morphologies can be created, and electrospinning can be combined with other processes. The process has unique advantages for electricity storage applications.

Schematic illustration of a basic electrospinning setup. Image Credit: Huang, A et al., eScience

Tailoring Silicon-Based Anodes with Electrospinning

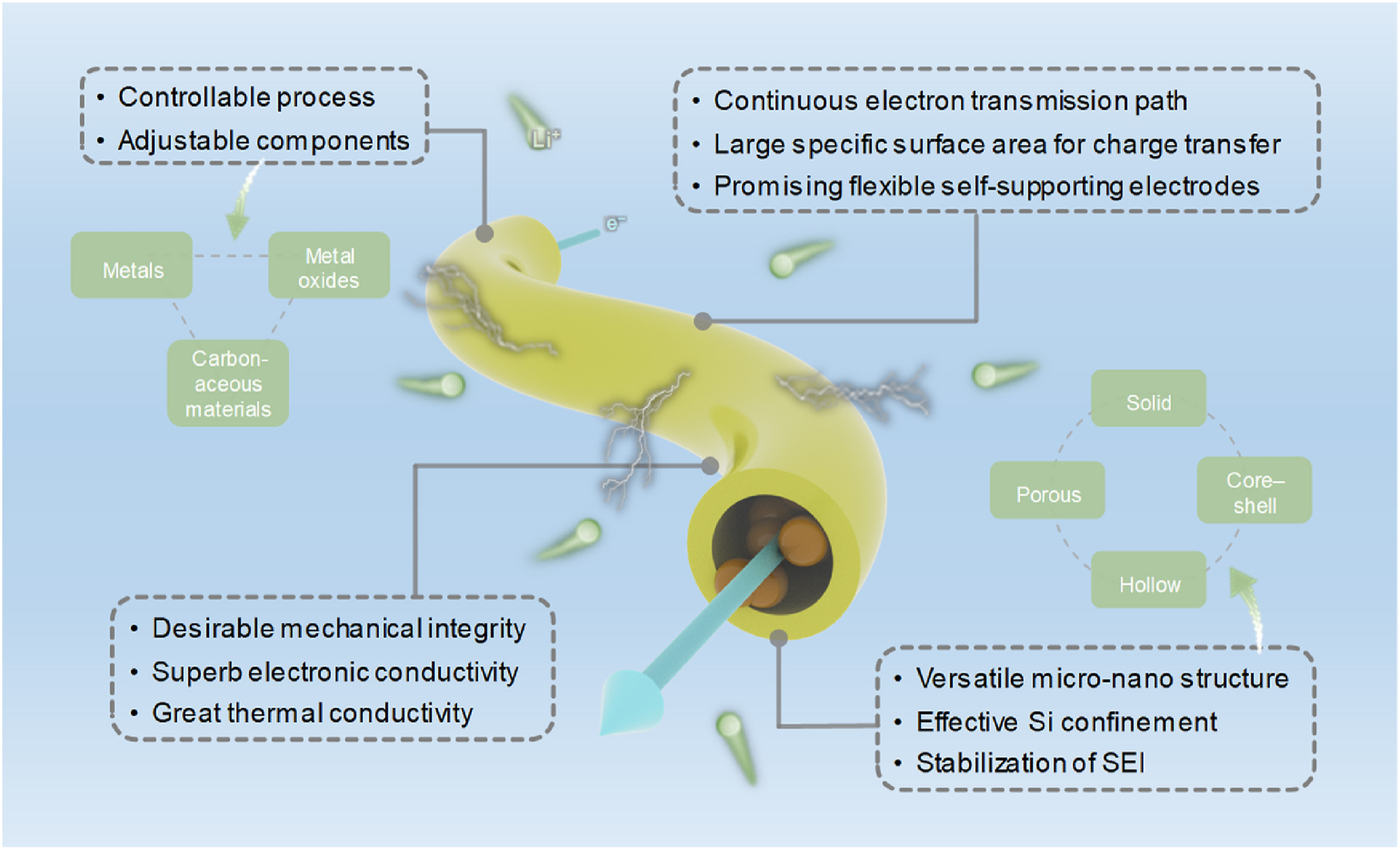

Aside from the ability to tailor silicon-based anode materials with specific morphologies, there are other advantages to electrospinning for their manufacture. The process provides continuous one-dimensional channels which enhance the speed of electron transfer in materials.

Moreover, electrospun silicon-based anode materials tolerate the volumetric change fluctuations during operation. This significantly improves their electrochemical performance, structural integrity, and electrical conductivity.

Additionally, electrospun silicon anodes possess superior self-supporting and flexibility properties, which make them attractive for inclusion as electrodes in wearable electronic devices. These advantages have driven the investigation of electrospinning for preparing silicon-based anode materials in recent years.

This has been the focus of a paper published recently in eScience. The authors have stated that there is a lack of literature on recent progress in this area. The study covers the preparation process, the design of electrospun silicon-based fibers with tailored nanostructures, the performance of electrospun materials, and provides a review of the history, development prospects, and perspectives on future research possibilities and new ideas for advances in the field.

The advantages of electrospun Si-based fibers as anodes for LIBs. Image Credit: Huang, A et al., eScience

The Future

The study has highlighted that there are a few companies that are currently focusing on using silicon and SiO in small electronic devices, and some are concentrating on developing high-mileage batteries. The current problems with material properties and design need to be overcome before large-scale commercial and industrial production can be realized.

However, surmounting these challenges will provide future opportunities for pioneering work which will facilitate a technological leap forward.

Additionally, the authors have identified that the kinetic and thermodynamic mechanisms that govern the electrochemical performance of electrospun silicon materials are poorly understood currently. Further investigation of electrochemical behavior and failure mechanisms are necessary to improve the lithium storage performance of electro-spun silicon-based anode materials.

The study has provided important information on the subject which will inform future research directions.

Further Reading

Huang, A et al. (2021) Tailoring the structure of silicon-based materials for lithium-ion batteries via electrospinning technology [online] eScience | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/pii/S2667141721000380

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.