Velo3D, Inc., a leading metal additive manufacturing technology company for mission-critical parts, has announced its first Sapphire® XC delivery. The Sapphire® XC, or “Extra Capacity,” is the company’s newest and largest metal 3D printer that delivers both faster production and larger parts. The Sapphire® XC is a scale-up version of the Sapphire® Printer, utilizing the same Flow™ print preparation software, the same Assure™ quality control software, and the same Intelligent Fusion® manufacturing process.

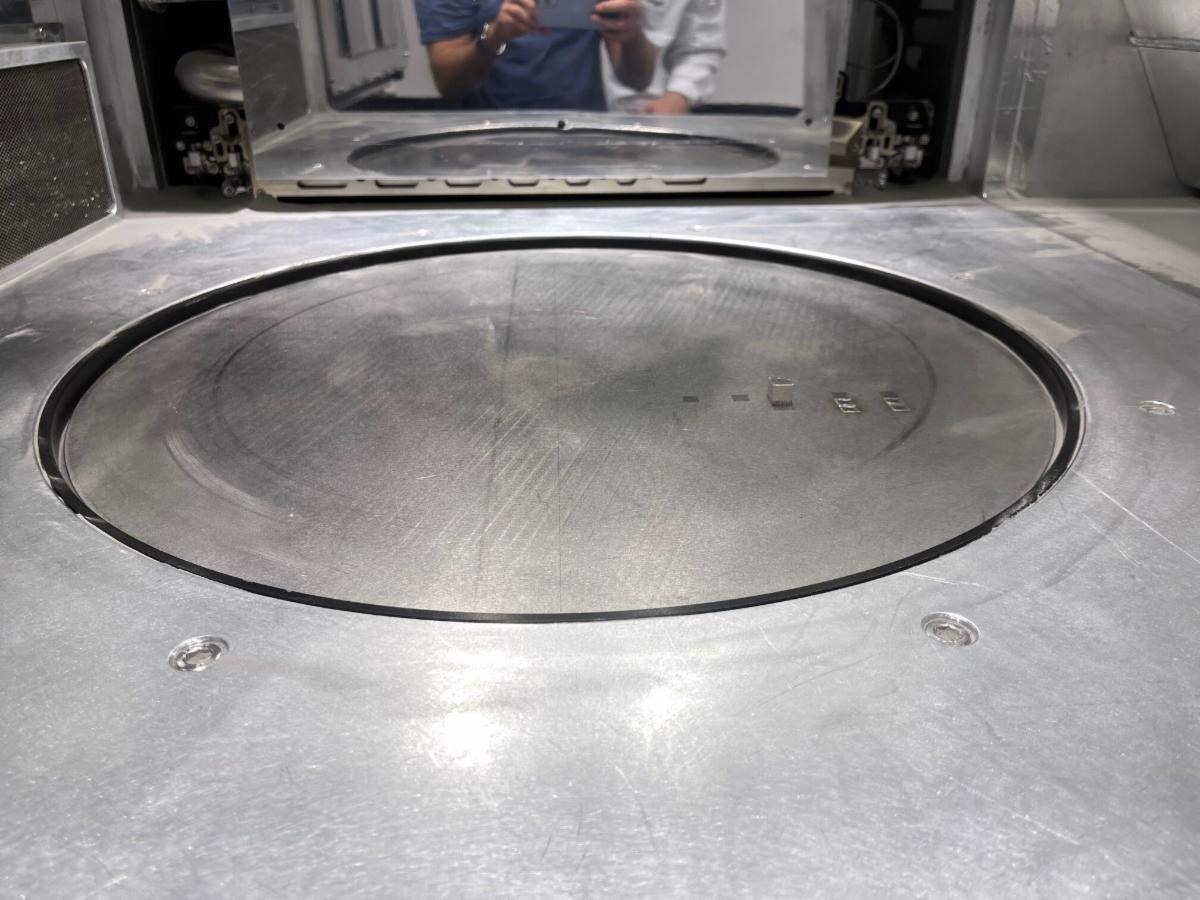

The extra-capacity build plate of the Sapphire XC metal 3D printer allows for larger parts, increased throughput and lower per-part costs. Image Credit: Velo3D, Inc.

The extra-capacity build plate of the Sapphire XC metal 3D printer allows for larger parts, increased throughput and lower per-part costs. Image Credit: Velo3D, Inc.

Sapphire® XC is built to enable a seamless transition of parts that were developed and qualified on Sapphire® to the larger, more productive Sapphire® XC, reducing the cost of producing parts by up to 75%. Sapphire® XC also expands the use of Velo3D’s production solution to parts that are up to 400% larger in volume than the largest parts possible with the original Sapphire®. The aerospace company receiving the new Sapphire® XC will use it to scale up production of its product that is built using the Sapphire® fleet of metal 3d printers they already have.

“I believe that the Sapphire® XC will quickly become the gold standard in advanced metal additive manufacturing,” said Benny Buller, Velo3D CEO and Founder. “Because our customer is already utilizing our end-to-end production solution, they can immediately and seamlessly move parts to Sapphire XC to achieve a phenomenal production rate increase. We made a huge effort to ensure that Sapphire® XC uses the exact same manufacturing process as Sapphire. The ability to move production seamlessly between different products was considered impossible when we started Velo3D, but I am proud to declare that we have unlocked this ability for our customers and partners. It is a huge accomplishment—our biggest achievement of 2021.”

Velo3D currently has a backlog of firm bookings for 17 additional Sapphire® XC systems as well as 19 additional reservations. This demand is driven by the lower production costs Sapphire® XC can enable for customers who have adopted the original Sapphire® printers and its ability to produce much larger parts. These improvements are largely driven by new features and capabilities the printer delivers, including:

- Larger build volume: The Sapphire® XC is one of the largest available laser powder bed fusion (LPBF) printers with a build volume of 600 mm in diameter and 550 mm in height— 400% larger volume than the original Sapphire® system.

- Additional lasers: The Sapphire® XC uses eight 1-kilowatt lasers to selectively weld powdered metal layer-by-layer. Velo3D’s Sapphire® system uses two 1-kilowatt lasers.

- Faster non-contact recoater: Compared to its Sapphire® system, Velo3D’s proprietary protrusion-tolerant recoater is now twice as fast on Sapphire® XC, significantly reducing non-productive overhead time.

All of these features come together to dramatically increase throughput by up to 400%, which lowers the cost of produced parts by up to 75%.

The ability to seamlessly transition from the Sapphire® to the Sapphire® XC is a key differentiator for the company. This is made possible by its end-to-end solution that preserves design intent and delivers predictable, repeatable outcomes.

The Flow™ pre-print preparation software analyzes part designs and prescribes a set of known recipes needed to manufacture the part. Customers simply upload the CAD file for a part they would like to print and the software’s integrated simulation engine creates a file that can be used across any device to build exactly the same part. As parts are printed, the Assure™ quality assurance and control system monitors the build and provides detailed reporting for full traceability layer by layer. This gives customers confidence that the parts produced are identical across Sapphire® printers.

The Sapphire® XC is able to print using a wide variety of materials that are often used in the production of mission-critical parts in the aviation, aerospace, defense, oil and gas, and energy industries. The list of available metals includes Inconel 718 & 625, Hastelloy® X, Hastelloy® C22, Aluminum, Scalmalloy©, and Titanium Ti-6Al-4V. Velo3D continually evaluates and qualifies new materials for use in its end-to-end solution.