In a study published in the journal Energies, a group of researchers from Poland recently analyzed the effect of graphite and shungite on the properties of dielectric elastomer-based materials such as polydimethylsiloxane. They analyzed the structures, mechanical properties, thermal stability, and dielectric properties of the resulting composites.

Study: Comparison of How Graphite and Shungite Affect Thermal, Mechanical, and Dielectric Properties of Dielectric Elastomer-Based Composites. Image Credit: Wirestock Creators/Shutterstock.com

The samples with an optimum mass of additives indicated an enhanced dielectric constant with a negligible decrease of strain at break. Additionally, samples containing graphite showed improved mechanical and dielectric properties regardless of the filler content, whereas samples containing shungite above 5 weight% indicated a decrease in tensile strength.

Dielectric Elastomer Composites

Electrostrictive polymers, also known as the dielectric elastomers or artificial muscles, belong to a class of smart materials when subjected to an electric field exhibit high degree of deformation than most magnetic alloys comprising shape memory and piezoelectric materials. These polymers are mostly used in modern industries involving complex levels of automated mechanical activities such as robotic manipulators, in which electromagnetism-based solutions are inefficient, bulky, and costly.

Furthermore, carbonaceous fillers significantly affect the mechanical properties such as elongation and durability of these dielectric elastomers. Expanded graphite is a widely used low-cost, carbonaceous, electronically conductive additive in dielectric materials with excellent dielectric properties, which is prepared by heating an oxidized graphite intercalation compound interlayer.

Shungite is another highly porous lustrous carbonaceous mineral complex containing non-crystalline carbon, silicates, a small number of metal oxides, and carbon allotropes such as nanotubes and fullerenes in its structure.

About the Study

In this study, researchers synthesized dielectric elastomer composite samples using polydimethylsiloxane (PDMS) as the polymer matrix, 10 grams of which was dissolved in 40 grams of n-hexane solvent followed by the addition of expanded graphite and shungite (33% carbon) into the mixture in weight ratios of 1, 3, 5, 10, and 15%. The prepared mixtures were ultrasonicated for 30 minutes followed by drying at 70 ℃ for five days in squared polystyrene Petri dishes.

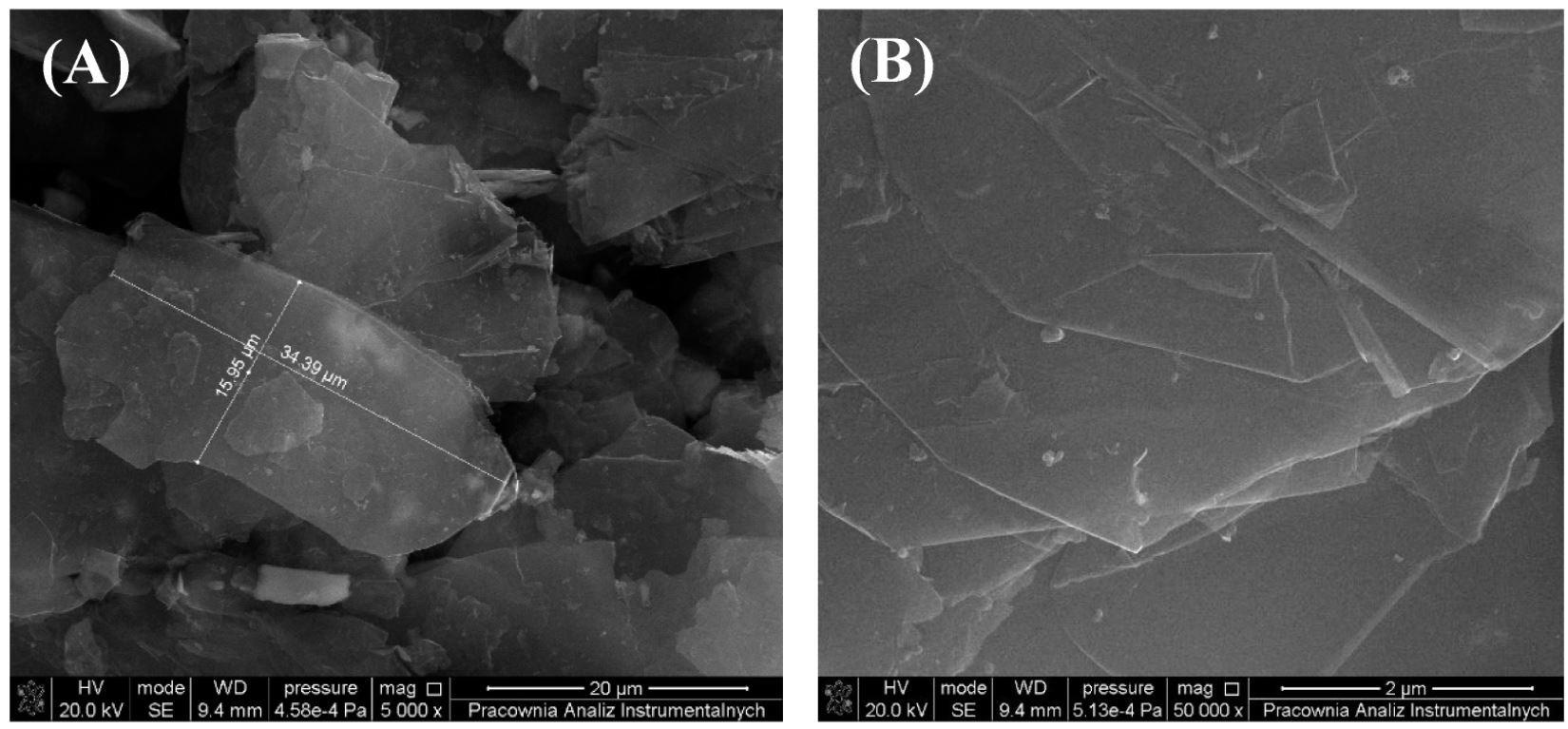

SEM images of graphite with magnification (A) 5000× and (B) 50,000×. Image Credit: Olewnik-Kruszkowska, E et al., Energies

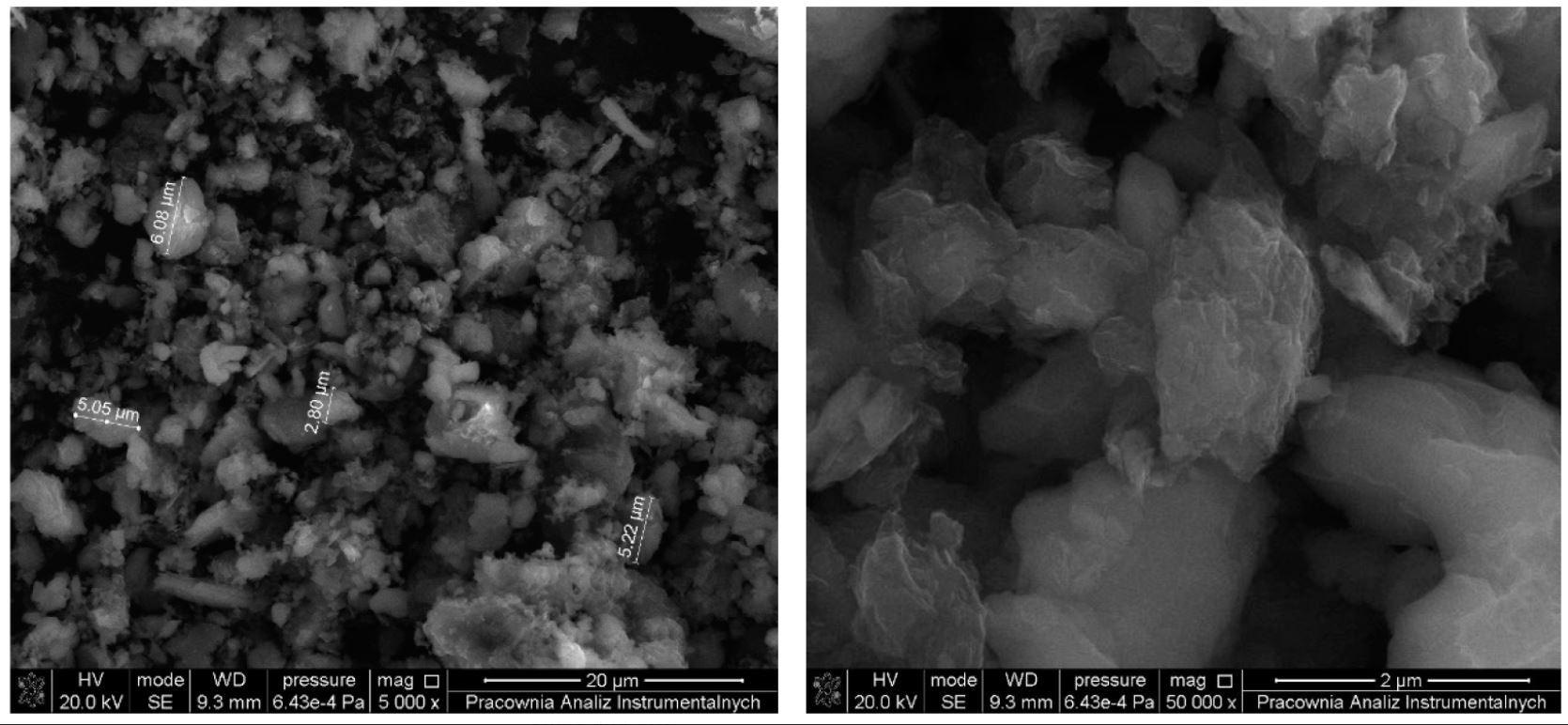

Subsequently, the morphology of prepared composite samples and the element mapping of the used fillers were studied using a scanning electron microscope (SEM) connected with an energy dispersive X-ray spectrometer (EDX). The thermal stability of the samples was analyzed using a thermal gravimetric analysis (TGA) and differential thermal analysis (DTA) instrument. Finally, dielectric measurements were performed by using a dual display LCR DE-5000 analyzer with an AC voltage of 600 mV and within a frequency range of 102 to 105 Hz at room temperature.

Observations

The SEM images indicated the presence of graphite flakes of 50 nm thickness in the PDMS matrix, whereas shungite particles were much smaller than the graphite. Additionally, the addition of graphite did not affect the morphology of the prepared composites, whereas, in the sample containing 15 weight% shungite, the formation of filler aggregates caused the differentiation of the surface morphology. Moreover, the cross-section morphologies samples containing 1, 10, 15 weight% of either filler showed uniform dispersion, while only for 3 and 5 weight% samples agglomerates of both fillers were visible near the top layer.

SEM images of the shungite with magnification (A) 5000× and (B) 50,000×. Image Credit: Olewnik-Kruszkowska, E et al., Energies

The TGA results indicated that graphite has more resistance to temperature changes than shungite. The samples containing graphite lost less than 3% mass up to 600 ℃, whereas shungite samples lost 5% and 10% mass at temperatures of 546.7 ℃ and 584.7 ℃, respectively. However, the formation of a char layer on the surface of the sample containing 15 weight% shungite resulted in a more thermally stable sample than samples with any compositions of graphite.

The dielectric properties study revealed that the addition of either of the fillers significantly enhanced the dielectric constant of the composite samples with a relatively low increase in dielectric losses. Moreover, there was a slight decrease of dielectric constant with the increase in frequency due to the reduction of space charge polarization attributed to dielectric dispersion. Also, the dielectric constants of shungite and graphite mixed composites were higher than only shungite-based samples.

Conclusions

The researchers studied the effect of the addition of two carbonaceous fillers namely, expanded graphite and shungite, in a dielectric elastomer matrix of PDMS using the solution casting method. The results indicated that the dispersion of graphite and shungite in the polymer matrix depends upon the number of fillers used. At lower concentrations, graphite samples demonstrated better thermal stability; however, at high concentrations, shungite samples demonstrated the highest thermal stability due to the formation of a char layer on the surface.

Also, samples containing graphite showed improved mechanical and dielectric properties regardless of the filler content, whereas samples containing shungite above 5 weight% indicated a decrease in tensile strength. Thus, both carbonaceous fillers are suitable candidates for dielectric application based on their availability and processing condition.

References

Olewnik-Kruszkowska, E., Adamczyk, A., Gierszewska, M., Grabska-Zielińska, S., Comparison of How Graphite and Shungite Affect Thermal, Mechanical, and Dielectric Properties of Dielectric Elastomer-Based Composites. Energies, 2022, 15, 152. https://www.mdpi.com/1996-1073/15/1/152

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.