In a recent study published in the journal Materials, researchers from Brazil analyzed polyethylene terephthalate (PET) sand as a replacement of quartz sand at different compositions and measured their compressive strength, flexural strength, density, capillarity, and water absorption.

Study: Recycled PET Sand for Cementitious Mortar. Image Credit: Dr. Norbert Lange/Shutterstock.com

Researchers found that PET sand is viable up to a content of 10%, which improves the mechanical properties of the mortar and without compromising its workability and incorporated air properties. However, above that the loss of properties is very excessive, especially at 24% it affects its hardenability.

Substitute Sands for Mortars and Portland Cement

Currently, quartz sand from rivers or dunes is used as fine aggregate in concrete and mortar, which is highly harmful to the environment owing to the lack of natural recovery of mineral resources, which are extracted at a much faster rate than they are formed. Also, the calcination of clinks at high-temperature releases harmful gases.

Many studies have tried to replace natural sand with reinforced concrete demolition (RCD) wastes, vermiculite in geo-polymeric mortars, rock residue in gypsum mortars for the restoration of historic structures, rock residue in cement mortars for block laying and wall cladding, and spherical glass waste particles.

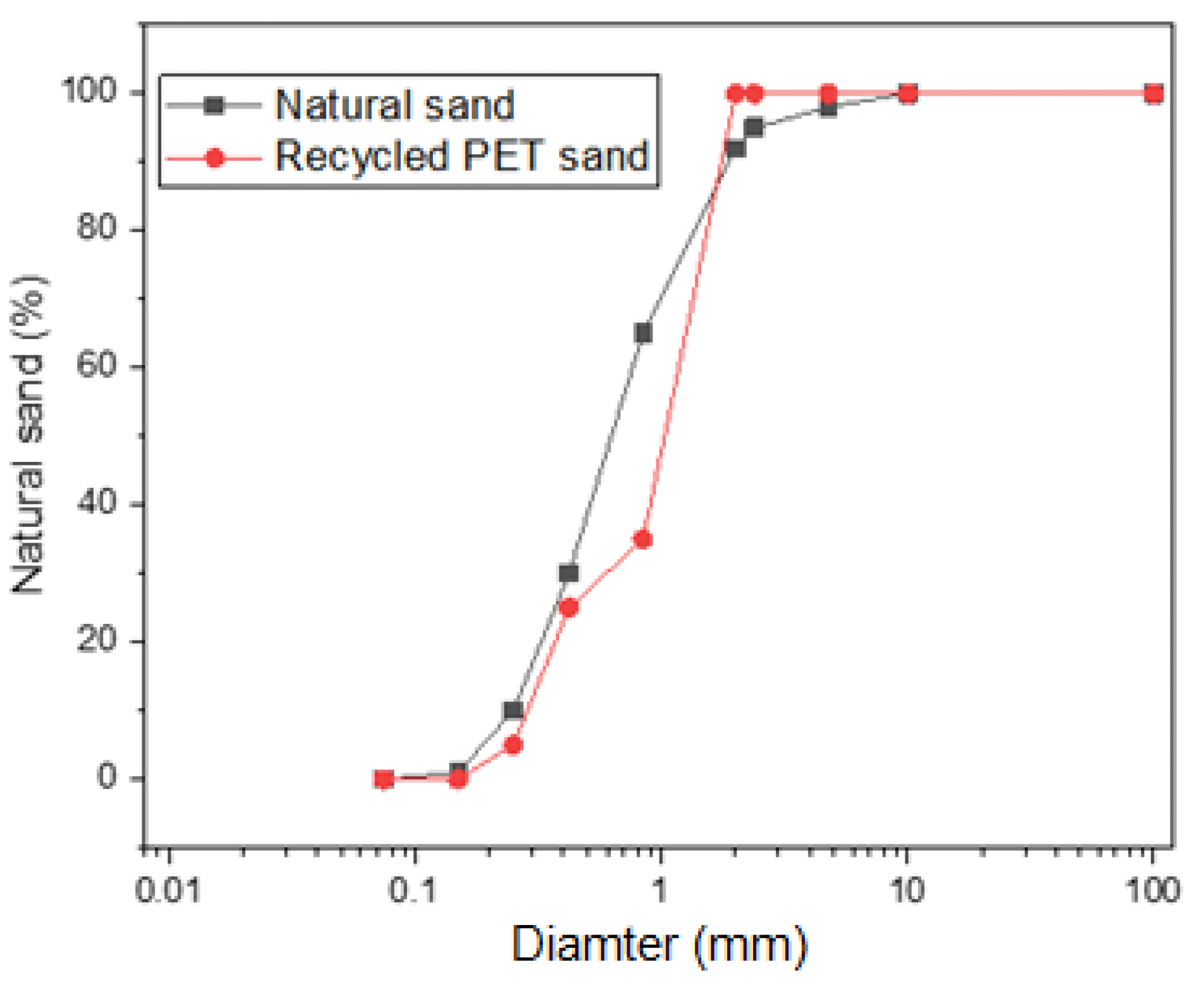

All previous researches indicate that the replacement sand should have adequate granulometry, packing, porosity, and inertness. Adequate particle size reduces porosity, contributing to the packing and mechanical strength, whereas inertness means, it must not interfere with the hydration of the cement and the reaction of other binders.

These factors contribute to mechanical strength, thermal conductivity, hardenability, workability of cementitious materials. PET has shown favorable packing order, ductility, and inertness when used in soil-cement blocks and reinforced polymer composites.

Granulometry of aggregates. Image Credit: Campanhão, A. et al., Materials

About the Study

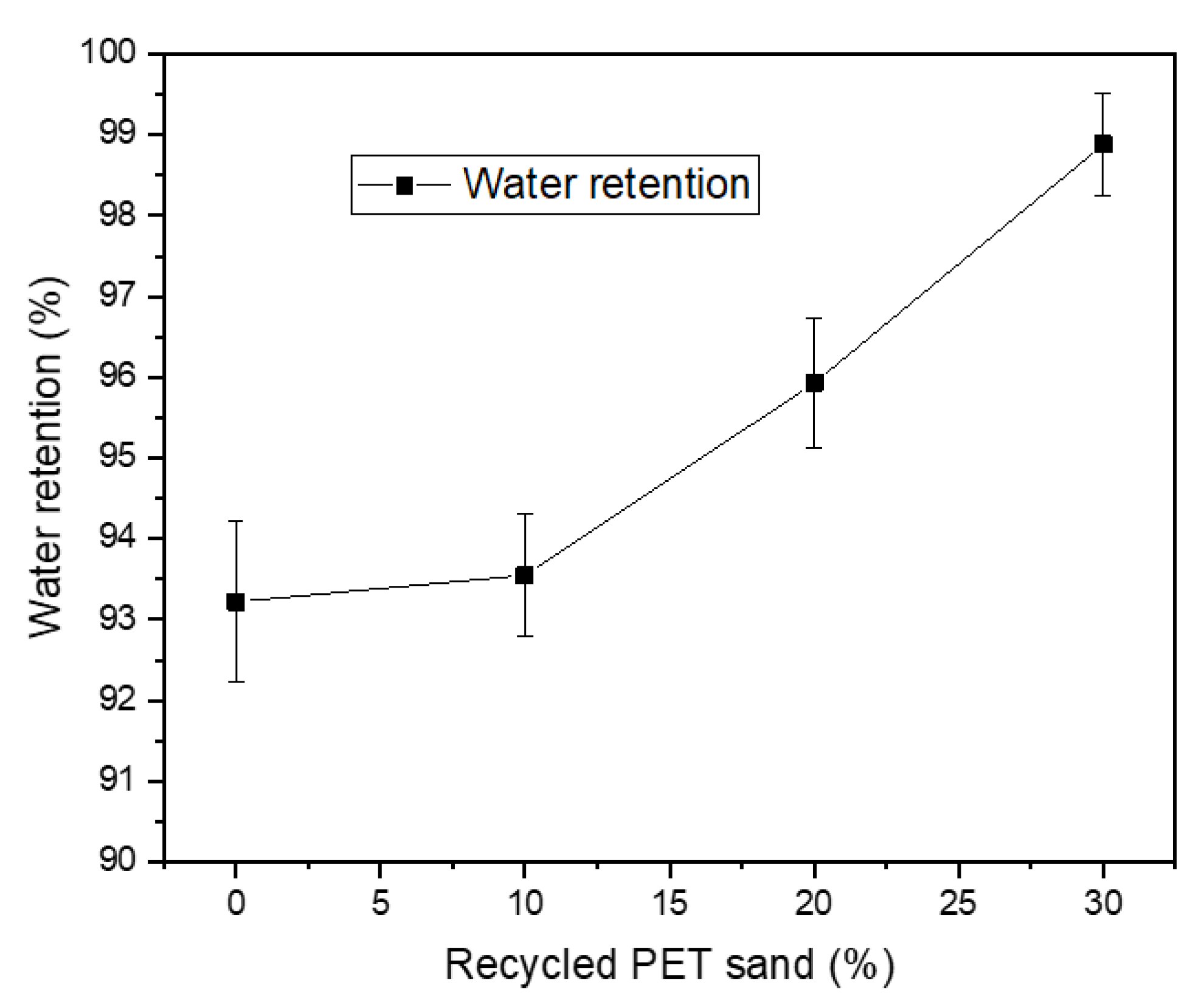

In this study, researchers evaluated the effects such as consistency index, incorporated air, water retention, water absorption, density, tensile strength in bending, and compressive strength of recycled PET sand when used as a substitute for natural quartz sand at composition levels of 0 to 30% in cementitious mortars.

The used ordinary Portland cement (OPC) composite samples had 20% blast furnace slag and 80% clinker, whereas the hydrated lime had 90% hydrated composite. The natural quartz sand and the recycled PET sand have similar granulometry as evident by their similar curvature coefficient and uniformity coefficient of aggregates. The mortar specimen of 40 x 40 x 160 mm3 were prepared and tested as per NBR 13276 and EN-BS 4551 standards with a composition of 1:1:6:1.4 (cement: hydrated lime: sand: water), in which the PET sand composition was varied between 0 to 30%.

Water retention results. Image Credit: Campanhão, A. et al., Materials

Observations

The consistency index results indicated that the recycled PET sand composition of 0% and 10% demonstrated had a compatible grain size within the scattering limit of 265 to 255 mm, whereas the 20% and 30% compositions indicated a high loss of workability due to the absorption of freely available water promoted by the recycled PET sand, which improved the spreading but increased the internal frictions of grains.

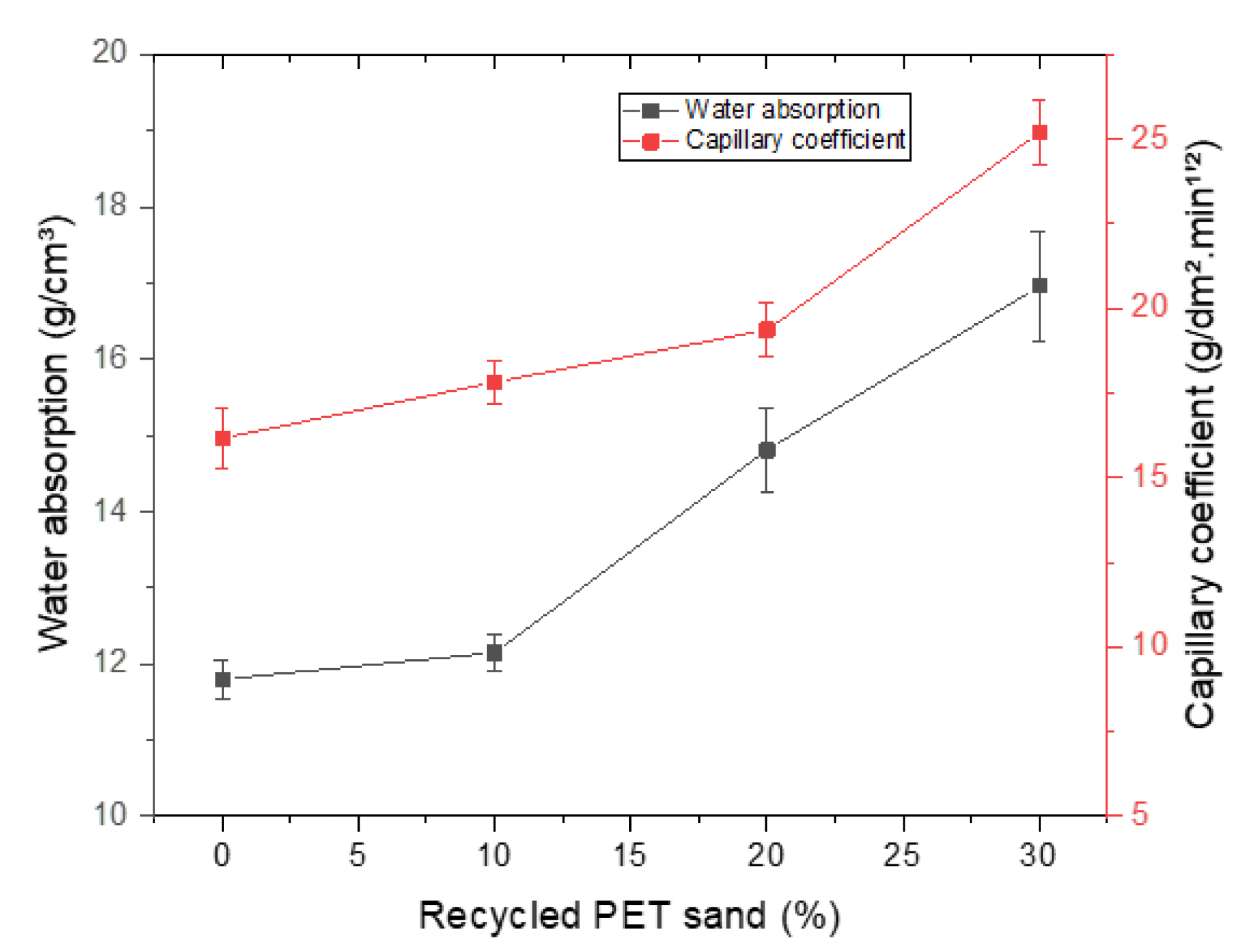

Moreover, the use of PET sand reduced the density of mortar specimens in the fresh state from 2.65 g/cm3 (i.e. in the case of natural sand) to 1.65 g/cm3. Also, the compositions 0%, 10%, and 20% had similar incorporated air around 7.5%, but the 30% composition had an excessive incorporated air content of 24% owing to the lack of homogeneity and formation of low adhesive surface between PET and cement interface. The incorporated air content had an adverse effect, as caused porosity in the hardened cementitious matrix and reduces mechanical strength.

Additionally, the 20% and 30% mortar compositions had inadequate water retention capacity higher than the preferable range of 75% to 95%. Repeating the similar pattern, the 20% and 30% mortar compositions showed inadequate flexural strength below 1.0 MPa.

Water absorption and capillary results. Image Credit: Campanhão, A. et al., Materials

Conclusions

In this study, researchers replaced 0 to 30% of natural quartz sand with recycled PET sand and studied its effect on mortar specimens.

The specimens with 10% or less composition of PET sand demonstrated values close and equivalent to the reference sample with only natural sand without any noticeable harm to any essential properties, whereas 20% and 30% composition samples indicated a drop in the consistency index, workability, excess incorporated air, high porosity, and low flexural and compressive strength. Hence, mortar with a low concentration of recycled PET and is a promising and eco-friendly option.

Reference

Campanhão, A., Marvila, M., de Azevedo, A., da Silva, T., Fediuk, R., Vatin, N., Recycled PET Sand for Cementitious Mortar. Materials 2022, 15, 273. https://www.mdpi.com/1996-1944/15/1/273

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.