.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 7 2022

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 7 2022A new paper published in the journal Materials by a group of researchers has demonstrated the potential and challenges of using phase change materials (PCM)-incorporated concrete in buildings.

Study: Phase-Change Materials in Concrete: Opportunities and Challenges for Sustainable Construction and Building Materials. Image Credit: Bannafarsai_Stock/Shutterstock.com

In concrete, the incorporation of PCM has demonstrated significant potential in clean area storage. However, the large-scale application of PCM-incorporated concrete has been hindered by adverse impacts of PCM on the durability and mechanical properties of concrete. Thus, researchers are trying to develop different techniques to incorporate PCM in concrete that can overcome these challenges.

Why use PCM-Incorporated Concrete?

Currently, the building sector utilizes a substantial amount of conventional power and natural resources across the world, thus contributing to environmental degradation and increased demand for energy. Consumption of energy by buildings is forecast to increase in upcoming years due to the construction of new buildings, which will further drive the energy demand.

Hence, these developments are not in line with the United Nations Sustainable Development Goals (UN SDGs). SDG intervention encourages the transition from fossil-fuel-based energy to renewable energy for attaining sustainability.

Significance of PCM-Incorporated Concrete for Sustainability

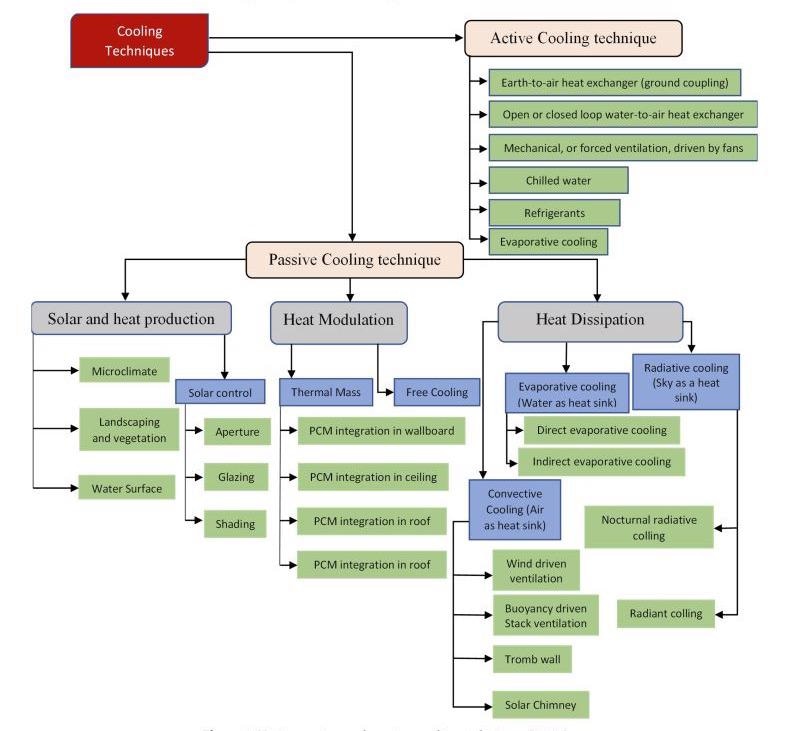

Currently, the focus has shifted toward passive cooling strategies that are sustainable in the long term. Passive cooling strategies such as the use of PCM-incorporated concrete can promote a sustainable future by helping to achieve net-zero carbon emissions from buildings. In the last decade, thermal energy storage (TES) has emerged as a promising technology for a low carbon future.

Various active and passive cooling techniques. Image Credit: Sharma, R et al., Materials

TES is a practical method that adheres to UN SDG principles concerning the use of clean energy for thermal comfort. Despite having certain deficiencies in mass and heat transfer, TES still demonstrates the largest heat storage density than sensible heat storage (SHS) and latent heat storage (LHS) methods.

Studies have shown that the use of PCMs can increase the TES needed for thermal comfort, which can reduce the projected energy demand and consumption of fossil fuels in the future.

PCMs can release and absorb heat at a constant temperature. PCMs can also store a significantly higher amount of heat per unit volume than SHS materials used in buildings such as rock, masonry, and water. Hence, LHS-based PCMs have been referred to as the most relevant TES material for practical building applications.

PCM and its Types

In the building sector, eutectic, inorganic, and organic PSMs are the commonly used PCM types. 20-32o is the accepted range of temperature for passive cooling of buildings with PCMs. Organic PCMs are either non-paraffin type or paraffin type. Paraffin is suitable for passive cooling and energy storage PCMs.

However, organic PCM has a lower rate of heat release/storage capacity owing to low thermal conductivity. Inorganic PCMs are referred to as metallic materials, nitrates, and salt hydrates. Properties such as non-flammability and high volumetric LHS capacities make them suitable for building applications.

However, phase segregation and separation and corrosion are the notable disadvantages of inorganic PCMs. Eutectic PCMs are referred to as the mixtures of organic and inorganic compounds. Single melting temperature and greater density than organics are the major properties of eutectic PCMs.

Techniques Used for Incorporating PCMs in Concrete

Microencapsulation, macroencapsulation, porous inclusion, and shape stabilization are the four common methods for incorporating PCMs in concrete. Low strength and stiffness are the major drawbacks of microencapsulated PCM. Macroencapsulation is similar to microencapsulation with minor differences. However, poor heat transfer and leakage are the major drawbacks of the technique.

Although the shape stabilization technique can address the issue of leakage, shape-stabilized PCM has lower thermal conductivity. The porous inclusion technique is mainly used to improve thermal inclusion. However, the use of all these techniques can increase porosity and decrease the density and strength of concrete, despite the improvements in thermal performance.

Techniques to Improve the Properties of PCM-Incorporated Concrete

Neutralizing or minimizing the effect of PCM on the mechanical properties of concrete is the only way to promote the field application of PCM-incorporated concrete. The adverse impact on the mechanical properties can be limited by depositing PCM in a lightweight aggregate and coating supplementary cementitious materials on the outer surface.

The use of nanomaterials in PCM, filling pipes with PCM, impregnating PCM in concrete pores from the surface, and adding carbon nanotube and silica fume during the paste phase have yielded better results than direct PCM-incorporation techniques.

Future of PCM-Incorporated Concrete

Efforts are on to improve the thermal conductivity of PCM-incorporated concrete by using materials such as metal foam and layered clay minerals.

This study focuses on different PCMs, their adverse effects on concrete properties, and ways to minimize the effects. Observations from the studies have demonstrated that the use of nanomaterials and additional cementitious materials can increase the strength of PCM-incorporated concrete. However, achieving a balance between thermal storage and mechanical properties remains a challenge for researchers. Thus, more research is required to eliminate the adverse effects of PCM on concrete.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Sharma, R. Jang, J.-G. Hu. J.-W. Phase-Change Materials in Concrete: Opportunities and Challenges for Sustainable Construction and Building Materials. Materials 2022, 15, 335. https://www.mdpi.com/1996-1944/15/1/335