.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 19 2022

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 19 2022A team of researchers recently published a paper in the journal Materials that demonstrated the crack-healing ability of ceramic composites at low temperatures.

Study: Self-Healing of SiC-Al2O3-B4C Ceramic Composites at Low Temperatures. Image Credit: An Mazhor/Shutterstock.com

Background

Ceramics are extensively used in certain complex environments owing to their high bending strength and hardness. However, brittleness is a major drawback of the material. Different toughening mechanisms and systems used to address the issue produce microcracks in the material and degrade the overall performance of the ceramic composite. Thus, the focus has shifted toward the self-healing mechanisms of ceramic materials, where cracks could heal spontaneously before causing any serious damage.

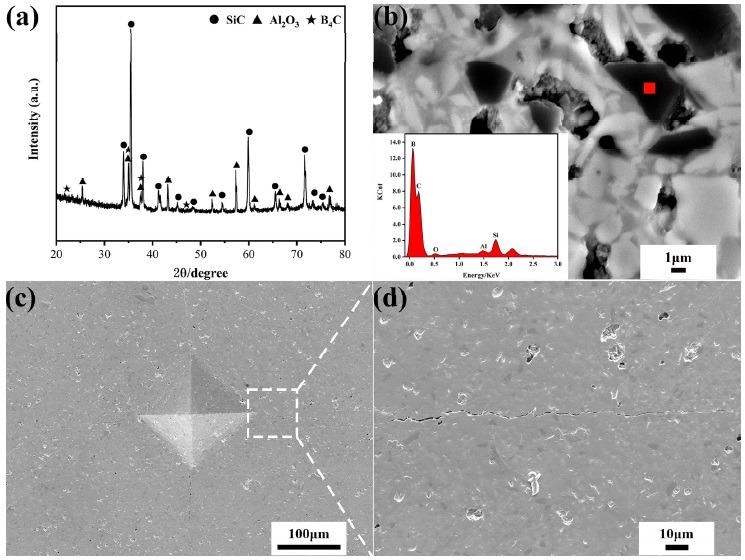

(a) X-ray diffraction pattern, back-scattering electron micrographs of phase composition (b) Vickers indentation (c) and crack (d) of SiC-Al2O3-B4C ceramic composite. Image Credit: Wang, B et al., Materials

Suitable healing agents were applied in ceramic composites to introduce the crack-healing ability. However, healing agents were mostly applied at moderate and high temperatures until now. Studies on the application of the healing agents at low temperatures (<800oC) have been sparse. In this study, the effect of the healing time and healing temperature of B4C (15% mass fraction) on the crack healing behavior in SiC/Al3O2 base ceramics was studied. The healing behavior was analyzed on macro-properties and the microstructure of the ceramics.

The Study

The raw materials used in the preparation of the sample for the study include glass powder, B4C, Al3O2, and SiC. A spark plasma sintering (SPS) process was used for preparing a sintered sample. The precision cutting machine was used to cut the sample into rectangular strips of size 3 × 4 × 20 mm. The cracks in the sample were prefabricated using a Vickers hardness test in order to simulate the cracks on the ceramic material surface, and the length of the cracks was measured by controlling the load.

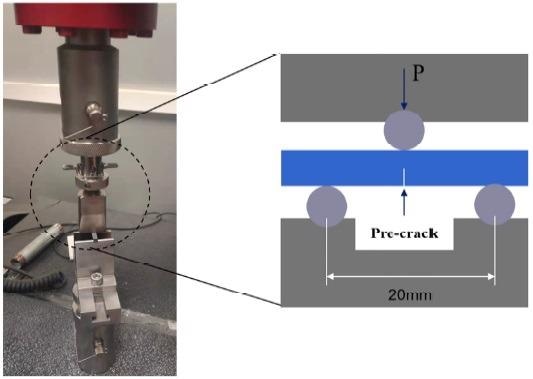

Cracks in the sample were healed for different temperatures (Th=600-800oC) and times (th=0-300 min) with a heating rate of 10 oC/min in air. The electronic universal testing machine was used for measuring the strength of the sample after and before healing by three-point bending. The three-point bending was performed at a loading rate of 0.5 mm/min with a span of 20 mm.

X-ray diffraction (XRD) was used for identifying the phase composition of the ceramic composite using Cu Kα radiation. A field emission scanning electron microscope (FE-SEM) helped observe the surface morphology of cracks in the sample.

A spectrometer attached to the FE-SEM was utilized for conducting energy-dispersive X-ray spectroscopy (EDS) analysis of the sample. The chemical compositions of surface oxides were studied using X-ray photoelectron spectroscopy (XPS), while the HSC chemistry thermodynamic software was used for calculating the thermodynamic data during the stoichiometric phase.

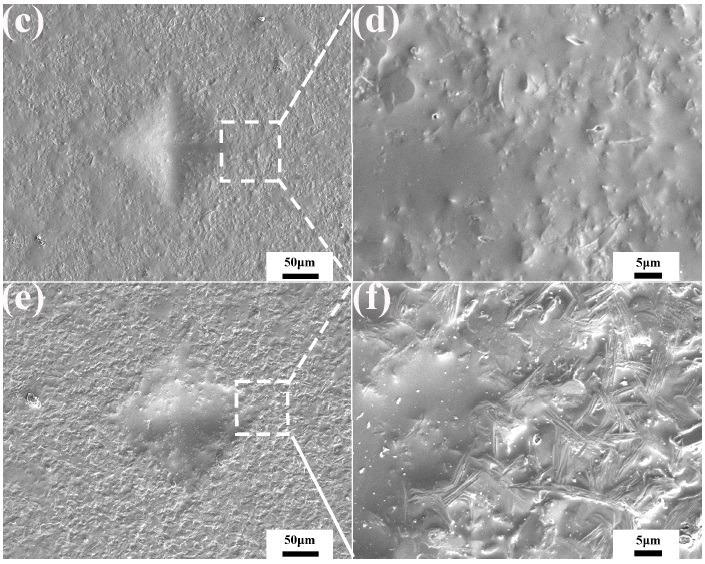

SEM morphology of Vickers indentation and cracks after healing at (a,b) 600 °C, (c,d) 700 °C and (e,f) 800 °C for 60 min. Image Credit: Wang, B et al., Materials

Observations

Apart from the crystalline phases of Al2O3 and SiC, no other side reactions were observed in the XRD pattern of sintered ceramic composites during the high-temperature sintering. The healing agent B4C was uniformly dispersed in the SiC/Al2O3 matrix, indicating the prerequisite for cracks healing.

Observations from the XRD patterns after healing the sample at 600-800oC for 60 min indicated that Al2O3 and SiC did not participate in the oxidation process, as their diffraction peak intensity remained the same at every temperature. The microstructure of the cracks healed at various temperatures for 60 min. The length of the cracks reduced after the sample was annealed at 600oC, indicating partial healing.

The cracks disappeared entirely and merged with the matrix when the sample was healed at 700-800oC. However, observations from the morphology of Vickers indentation indicated that cracks annealed at 700oC at different times. Although the cracks disappeared completely after the sample was healed for 30 min, several pores were produced after the sample was healed for 300 min. Thus, healing the sample for a long duration resulted in multiple defects and several pores in the sample, adversely affecting the properties of the ceramic material.

The flexural strength of the pre-crack samples was healed at various temperatures for 60 min. After healing the sample at 600oC, the flexural strength was recovered partially, while at 700oC the flexural strength recovered significantly. However, the flexural strength decreased at 800oC owing to the increase in the oxidation rate. At 700oC, the flexural strength recovered substantially when the sample was healed for 30 min. B4C showed an optimal self-healing behavior at 700-800oC.

As the oxidation reaction of the healing agent B4C was primarily responsible for the crack healing behavior, the recovery of the flexural strength mainly depended on the healing temperature and time. Observations from the XPS analysis indicated that B4C participated in oxidation-induced crack healing, while the observations from the SEM morphologies also indicated that B4C is effective for repairing cracks.

Schematic diagram of three-point bending of sample. Image Credit: Wang, B et al., Materials

Significance of the Study

This study demonstrated that rapid healing of prefabricated cracks at low temperatures improves the mechanical properties, service life, and utilization rate of ceramic materials. Cracks in the composite can be completely healed at 700oC for 30 min, leading to a substantial recovery in flexural strength. The good crack-healing ability of the SiC-Al2O3-B4C ceramic composite at low temperatures can make the material highly useful in several applications in the future.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Wang, B., Tu, R., Wei, Y. et al. Self-Healing of SiC-Al2O3-B4C Ceramic Composites at Low Temperatures. Materials 2022, 15, 652. https://www.mdpi.com/1996-1944/15/2/652