A study in Materials has compared the effects of ash derived from both sunflower stalks and corn cobs on the compressive strength of concrete, exploring the use of these waste materials to improve the sustainability of the cement industry.

Study: Corn Cob Ash versus Sunflower Stalk Ash, Two Sustainable Raw Materials in an Analysis of Their Effects on the Concrete Properties. Image Credit: EsfilPla/Shutterstock.com

The global cement industry is responsible for vast amounts of carbon dioxide emissions. This has led to increasing research into sustainable alternatives such as additives sourced from agricultural waste which possess cementitious properties.

The Need for Sustainable Alternatives for the Cement and Concrete Industry

The cement and concrete industry plays a huge part in driving global climate change. 2.3 gigatons of CO2 were emitted by the industry in 2019, which accounted for 7% of total global emissions. By 2030, global production of cement is predicted to be 4.83 billion tons, which is a tenfold increase on current estimates of 4.1 billion tons. Rapid industrialization, economic growth, and increasing urban density are drivers of this growth in production and emissions.

There is an urgent need to rapidly and decisively cut carbon dioxide emissions to net-zero by 2050 to avoid the worst effects of a rapidly warming globe. Climate change has been linked to worsening extreme weather events, impacts food security, increased risk of wildfires, heat stress in urban areas, loss of biodiversity, and may lead to worsening conflict and the phenomenon of climate refugees. As a major emitter of carbon dioxide, the cement industry must change its practices.

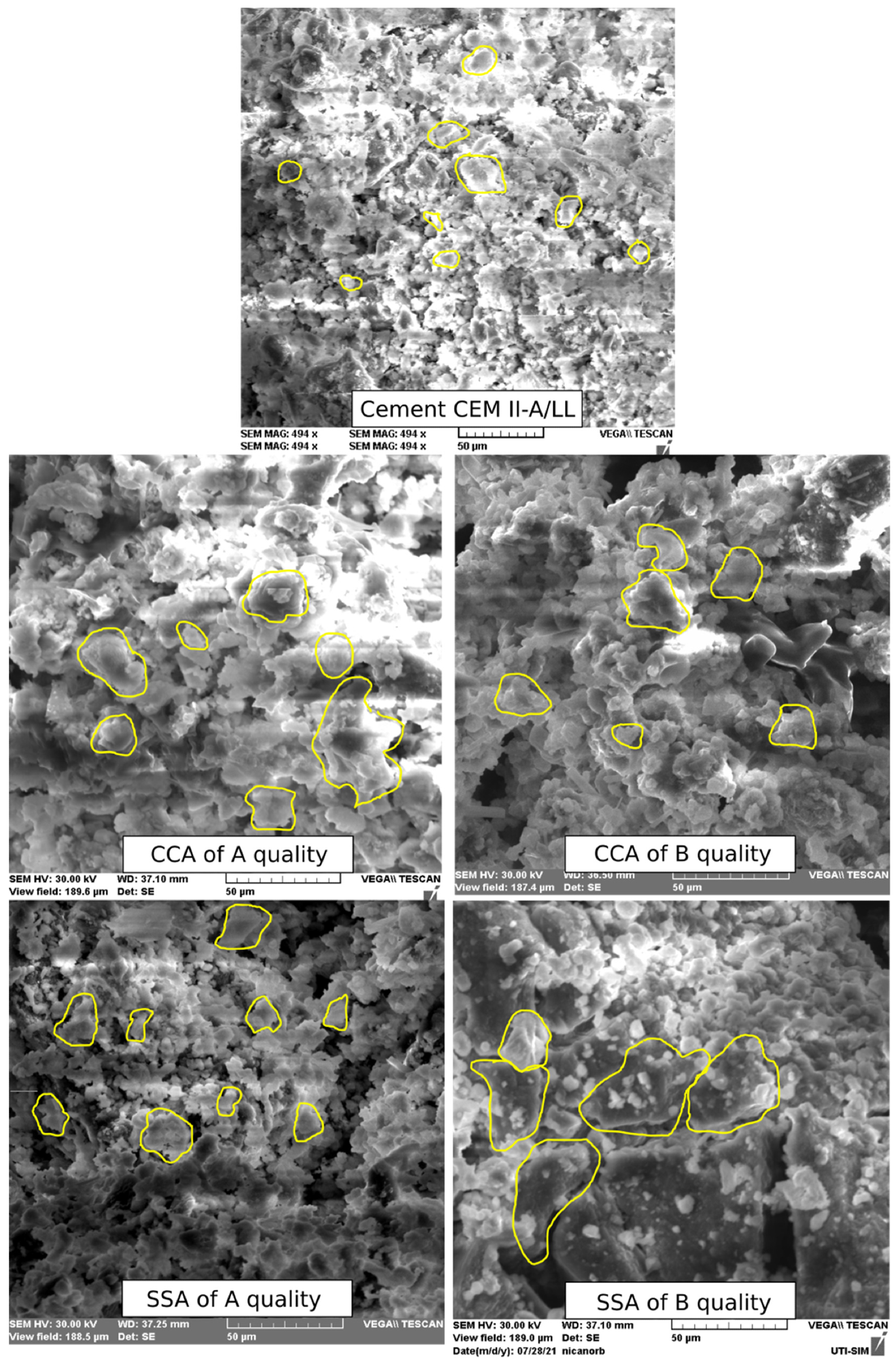

The SSA of A and B quality and CCA of A and B quality, compared with the cement aspect. Image Credit: Șerbănoiu, A.A. et al., Materials

Sustainable Cementitious Materials

Alternative, sustainable, supplementary cementitious materials (SCMs) have been explored in recent years to reduce CO2 emissions. Advantages of SCMs include less process heating, the ability to reclaim and reuse waste materials from various industrial sectors in line with the circular economy concept, smaller CO2 emissions, and improvements to some of the properties of concrete.

Amongst SCMS, there has been significant attention on materials obtained from vegetation. Studies have recently investigated SCMs, including those obtained from the ash of rice husks, corn cobs, sugarcane, wheat, straw, sunflowers, and many other organic waste materials that are by-products of the food and agriculture industries.

Some studies have demonstrated that, in the presence of calcium hydroxide, lignocellulosic ash that contains significant amounts of alumina and silica can develop pozzolanic activity. This increase in pozzolanic activity leads to improvements in the cementitious properties of concrete.

Resistance to the action of hydrochloric acid: (a) Specimens immersed in 18% HCl solution; (b) Specimens’ aspect after 10 days of immersion in 18% HCl solution. Image Credit: Șerbănoiu, A.A. et al., Materials

Corn Cob Ash and Sunflower Stalk Ash

Maize is a major staple crop in many parts of the world, being mainly grown in the USA, Latin America, China, Eastern Europe, and South Africa. Sunflower crops are grown in areas including Russia, South Africa, and Southern Europe. These crops are significant and widely available sources of lignocellulosic fibers and materials.

Corn cob ash has been studied extensively in recent years as an SCM for partial cement replacement in concrete, with mixed results. Improved resistance to sulfates and less water absorption have been demonstrated. Some studies have indicated using corn cob ash as an SCM reduces the compressive strength of concrete. Other research has determined that corn cob ash reduces the concrete slump, whereas other studies have found it is increased. Further research has demonstrated the advantages of composite corn cob/sawdust ash.

Sunflower stalk ash has been studied much less extensively than corn cob ash. Some studies have been performed on properties such as compressive strength and abrasive resistance of sunflower stalk ash SCMs. Studies have indicated that the optimal replacement rate of sunflower stalk ash in cement is 2.5%. Other research has indicated that sunflower stalk ash improves compressive strength and CSH amount, and decreases free lime content, with the optimal replacement rate in cement being 24 wt%.

SEM images of CCA, SSA and cement at the magnification rate of 50 µm. Image Credit: Șerbănoiu, A.A. et al., Materials

The Study

The study in Materials has sought to compare the effects of corn cob and sunflower stalk ash on normal concrete’s mechanical and durability properties. To the authors' knowledge, there are very few studies on the use of sunflower stalk ash in concrete production, and thus, this study is novel due to its comparative analysis of both SCMs.

The aim of the research was to develop a cementitious material with comparable mechanical and durability properties as ordinary concrete, with added benefits in terms of cost, sustainability, and energy efficiency. In the research, 8 mixes of concrete and sunflower stalk ash SCMs were developed, at 2.5% and 5% vol. % cement replacement and quality A and B.

![Mass loss due in case of chemical attack of 18% HCl solution [%].](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_58008_16431141162856212.png)

Mass loss due in case of chemical attack of 18% HCl solution [%]. Image Credit: Șerbănoiu, A.A. et al., Materials

Tests were performed, including the concrete’s compressive strength at 28 days and 3 months, splitting tensile strength, flexural tensile strength, and resistance to hydrochloric acid and repeated freeze-thaw cycles. The authors concluded that both SCMs reduced the tensile and compressive strength of concrete, but improved resistance to hydrochloric acid and freeze-thaw cycles.

In general, improvements were observed as the content of ash increased. Future directions identified by the authors are the effects of larger concentrations of corn cob and sunflower ash contents as additives or cement replacement materials on the freeze-thaw cycle.

Further Reading

Șerbănoiu, A.A. et al (2022) Corn Cob Ash versus Sunflower Stalk Ash, Two Sustainable Raw Materials in an Analysis of Their Effects on the Concrete Properties [online] Materials 15(3) 868 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/3/868

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.