.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 26 2022

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 26 2022In a study published in the journal Materials, researchers discussed the use of reactive multilayer thin films to coat tungsten wires to induce an exothermic reaction. The heat generated from this reaction was used to liquify materials with low melting temperatures and block the propagation of cracks in metallic materials.

Study: Development of Actuators for Repairing Cracks by Coating W Wires with Reactive Multilayers. Image Credit: Whitelion61/Shutterstock.com

Background

Metal1/Metal2 reactive multilayers such as Al/Ni multilayers are energetic materials with a bilayer thickness or nanometric period. Others like Ni–Ti can be used to prepare thin films of NiTi shape memory alloy with excellent mechanical properties.

Exothermic reactions can occur between the metals under certain conditions, which may lead to a self-propagating high-temperature synthesis (SHS). Reactive multilayers are usually deposited by physical vapor deposition techniques such as sputtering or DC magnetron sputtering.

Due to the exothermic and self-propagating properties of reactive multilayers, they are used as highly localized heat sources in many applications. Some of these applications take advantage of the heat released and the nanometric character of these reactive multilayer thin films to improve diffusion bonding. Since they are localized heat sources that promote joining, they can be used in self-healing applications where the released heat promotes the melting of repairing material.

The Study

In the present study, researchers deposited Ni/Me (Me = Al, Ti) multilayers onto tungsten wires of diameters 0.05 and 0.20 mm using a direct current (DC) magnetron sputtering from two targets - Ni and Me. In order to minimize cross-contamination and prevent atomic flux mixing, the researchers placed a stainless steel shield between the two targets.

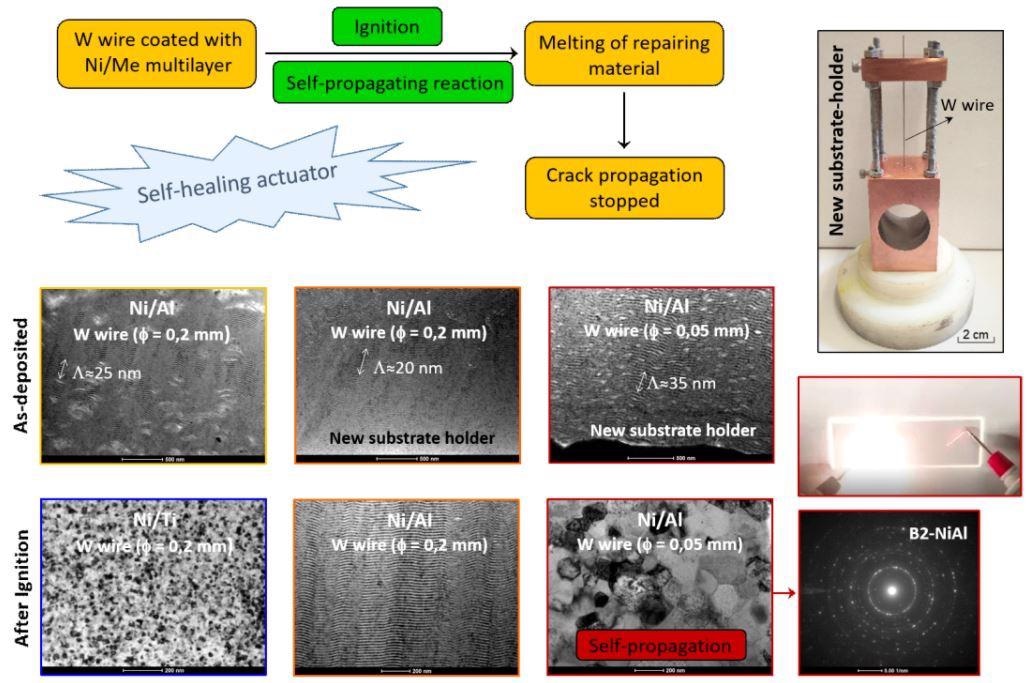

Image Credit: Santos Silva, G et al., Materials

Energy dispersive spectroscopy (EDS) was used to evaluate the average chemical composition in the multilayer thin films. On achieving the desired chemical composition, the team deposited the Ni/Me multilayer thin films onto the W wires of varying diameters.

The depositions help obtain films with almost equiatomic average chemical composition and a bilayer thickness in the range of 20 to 50 nm. The authors also used electron microscopy to analyze the cross-section of the film before and after electrical ignition.

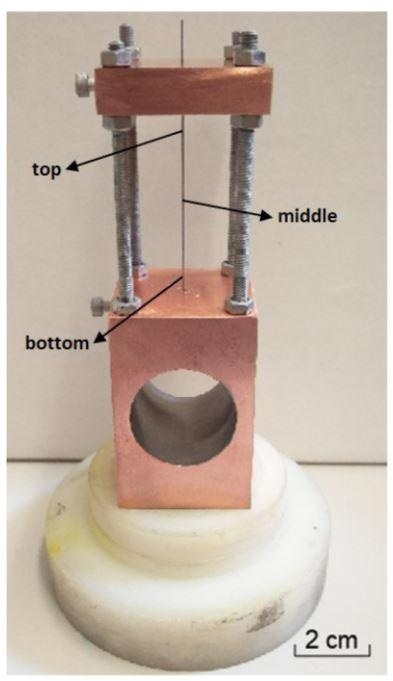

The new substrate holder dedicated to the coating of wires. Image Credit: Santos Silva, G et al., Materials

Results

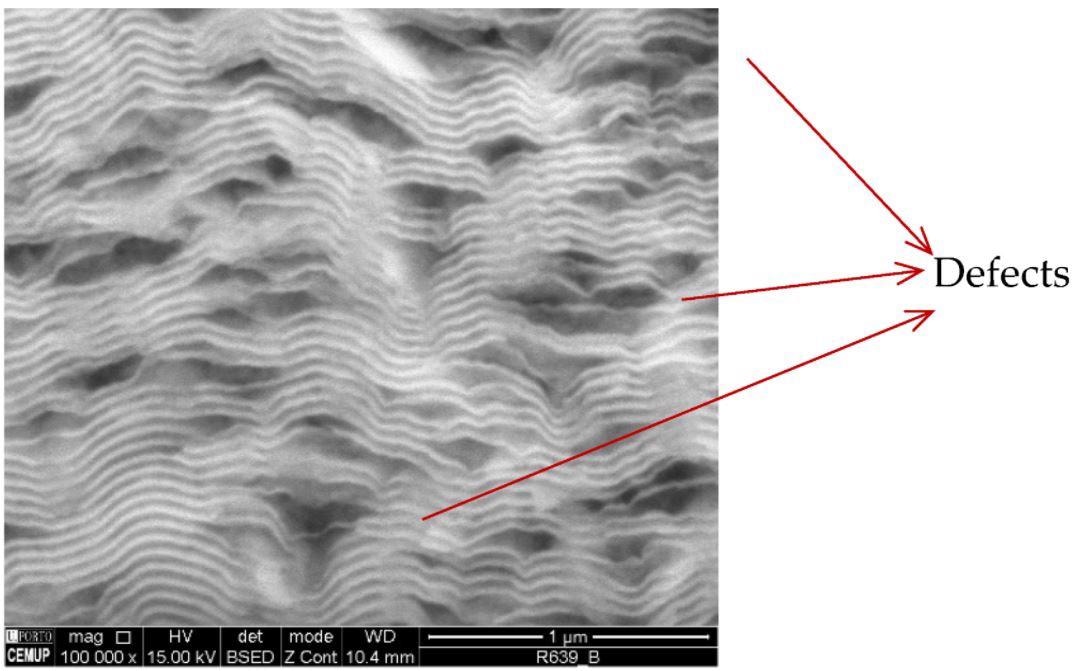

The results showed that the modulation period of the multilayer was nearly 50 nm. Several defects of submicrometric size were identified as dark regions in the scanning electron microscopy (SEM) images. Al-rich defects were observed in the transmission electron microscopy (TEM) bright field (BF) images. In addition to defects, zones of well-defined alternate nanolayers were also observed along with undefined zones in both periods. The defect sizes increased as the period increased.

The presence of an Al3Ni intermetallic phase was explained by the local reaction between Ni and excess Al during deposition without substrate cooling. Differential scanning calorimetry (DSC) measurements showed that the reaction occurs below 200°C for intermediate periods between ~25 and ~40 nm.

The team developed a new substrate holder to reduce defects and enhance the quality of the Al/Ni films, which allowed a significant reduction in previously observed defects. No discernible defects were observed in the Ni/Ti thin films, regardless of the type of substrate holder. However, the Ni + Ti reaction was in a non-self-propagating mode after electrical ignition. By passing a current through a wire of ϕ = 0.05 mm that is coated with an Al/Ni thin film, the team promoted a flash of light, which signaled the start of a self-propagating reaction. The product of the reaction was a B2-AlNi intermetallic phase.

BSE SEM cross-section micrograph of an Al/Ni thin film with a period close to 50 nm deposited onto a W wire (ϕ = 0.20 mm). Image Credit: Santos Silva, G et al., Materials

According to chemical composition results, there was a slight Ni enrichment, and the electron diffraction pattern was mainly indexed as B2-AlNi, despite some low-intensity peaks being present indicating a Ni-rich minor phase like AlNi3.

Conclusion

The deposition of nanoscale reactive multilayer thin films onto small diameter wires is a challenging task. The present study showed that coating tungsten wires with reactive multilayers could help in crack filling and turn the wires into self-healing actuators.

While TEM confirmed the nanostructured character of Ni/Me multilayer thin films deposited onto tungsten wires, a new substrate holder resolved the defects, allowing the preparation of more homogeneous films throughout the wires. In the Ni–Ti system, multilayer thin films without any defects were deposited independently of the wire diameter, substrate holder, or the modulation period.

In conclusion, self-propagation along with heat release illustrated in this method of producing multilayer-coated W wires is very promising in the development of actuators that can be used for self-healing applications.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Santos Silva, G.; Maj, L.; Morgiel, J.; Vieira, M.T.; Ramos, A.S. Development of Actuators for Repairing Cracks by Coating W Wires with Reactive Multilayers. Materials 2022, 15, 869. https://www.mdpi.com/1996-1944/15/3/869