Thin-film resistance temperature detectors are thin film-like devices that are generally made of platinum and used for temperature measurement. This is possible because an increase in temperature is proportional to an increase in platinum resistance. Therefore, this linear relationship can be modeled and applied to measure temperatures reliably.

Image Credit: Iaremenko Sergii/Shutterstock.com

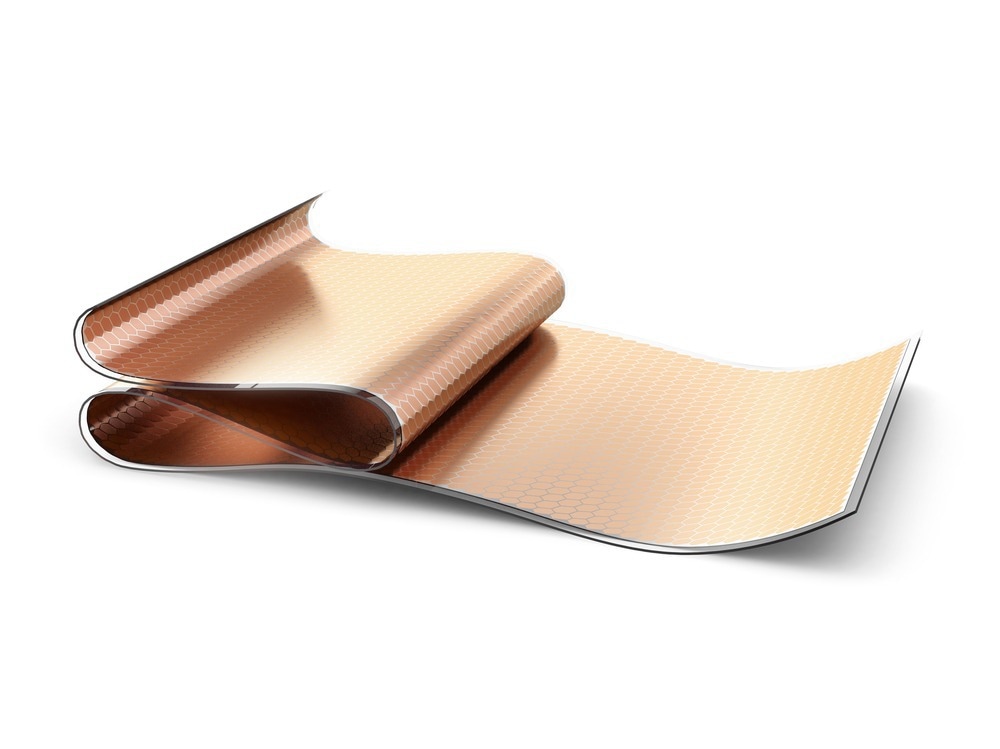

A thin film is a material layer that can be fractions of a nanometer thin to several micrometers thick. Thin-film materials are used in semiconductor devices, integrated circuits, solar cells, audio and video systems, compact discs, computer chips, wireless communications, telecommunications, emerging multifunctional coatings, cutting technologies, etc.

Materials that show similar patterns can be used in the same function; however, the stability, accuracy, and repeatability of the system are very crucial.

The Use of Gold in Thin Film Materials

Due to their distinctive performance, gold thin films have recently piqued the interest of corporations and researchers, particularly for optical applications. They are attractive because of their strength, malleability, inertness to oxidation, flexibility, and ability to conduct electricity and thermal energy. Gold is also an ideal material in thin films due to its ability to tolerate significant temperature changes.

Gold thin-film metals are often seen as the most significant signal amplification components in electrochemical and optical sensor applications.

Worth noting are observations of a study published in the Canadian Journal of Physics which reported that when the thickness of a gold thin film exceeds a critical value, the electrical resistivity of the film drops dramatically and approaches the resistance of bulk gold. This is an essential factor to consider during the production process.

Why is Heat Treatment Conducted for Thin Films

In thin-film structures, the tiny structure and small dimensions exert additional demands on the characteristics of the film. The microstructure of the thin film, which is a function of the deposition processes and associated parameters, as well as post-treatment, is crucial in defining the behavior and properties of the films.

Heat treatment is generally done to improve the structure and mechanical properties of metals and alloys. Several types of heat treatment exist and provide different outcomes for different metals and alloys. Heat treatment can affect the microstructure, hardness, crystallinity, grain size, texture, roughness, electrical resistivity, and residual stress.

After heat treatment, technologies such as Raman spectroscopy, scanning electron microscopy, X-ray diffraction, and atomic force microscopy can be used to study the structural, morphological, and surface roughness of the samples.

Applications of Heat-Treated Gold Thin Film Resistance Temperature Detectors

In the case of gold, a study recently published in the journal eTransportation focused on gold thin films as temperature detectors, which play a central role in the management of heat produced in proton exchange membrane fuel cells.

Proton exchange membrane fuel cells have emerged as one of the most promising prospects for renewable energy conversion devices in recent years due to their high energy density and zero-carbon emission. Durability is necessary for commercialization, and the quality of heat management influences the lifetime of the fuel cell.

The researchers aimed to fabricate a gold thin film, then enhance its properties through heat treatment.

First, the researchers created a micro-electro-mechanical system-based gold thin-film resistance temperature detector. Then low-temperature heat treatment was used to improve the performance of the resistance temperature detector, which helped achieve good linearity and low thermal hysteresis.

Finally, the gold thin film was utilized as a resistance temperature detector to measure temperatures in the proton exchange membrane fuel cell's cathode catalyst layer under various current loads and relative humidity.

Their results revealed that current loads are positively correlated to temperature changes. The greater the current, the greater the Joule and irreversible heat generated. Also, the anode and cathode relative humidity had a more complex impact on temperature evolution, depending on the water concentration in the electrode sites, which was controlled not only by relative humidity but also by the oxygen reduction reaction. Flooding occurred when the water content in the electrode area was too high.

In another older study, published in the Journal of Vacuum Science and Technology B: Microelectronics and Nanometer Structures, the researchers explore the thermal and long-term stability of gold thin films. They investigated the effect of a post-deposition thermal treatment on gold thin films in terms of stress in correlation with their structure and microstructure.

The films exhibited tensile stress and below 100-150 degrees Celsius, and sputtered films showed no appreciable variation in grain size or tension. An increase in grain size and a linear increase in tensile stress were seen after annealing both the evaporated and electroplated films at temperatures higher than the deposition temperature. Furthermore, the existence of broad voids led to stress evolution with time in electroplated films, which had reduced as-deposited stress but less thermal stability.

Challenges of Using Gold Thin Films

Some difficulties encountered throughout the manufacturing and treatment processes included correctly sustaining the pure thin film and maintaining it in an annealed condition by appropriate heat treatment of the materials so that it does not alter physically. In addition, the thin film must be stored in a contamination-free environment to avoid chemical alterations.

In summary, gold thin films are very desirable for use as temperature detectors in microdevices. This is supported by many beneficial properties such as flexibility, malleability, strength, inertness to oxidation, and the ability to conduct electricity and thermal energy. Heat treatment also proves to be a way to enhance the desirable properties of gold thin films. This will continue to broaden their applications to new technologies.

References and Further Reading

Ahn, C., Park, H., Kim, H.H., Park, S., Son, C., Kim, M., Lee, J.-B., Go, J. (2013). Direct fabrication of thin-film gold resistance temperature detection sensors on a curved surface using a flexible dry film photoresist and their calibration up to 450 °C. Journal of Micromechanics and Microengineering 23, pp.065031. https://doi.org/10.1088/0960-1317/23/6/065031

Brett, S. (2021). An Overview of Gold Thin Films: From Sensors to Cell Culture [WWW Document]. AZoNano.com. URL https://www.azonano.com/article.aspx?ArticleID=5862

Gilani, T., Rabchuk, D. (2017). Electrical Resistivity of Gold Thin Film. Canadian Journal of Physics 96. https://doi.org/10.1139/cjp-2017-0484

Malek, C.K. (1991). Effect of thermal treatment on the mechanical and structural properties of gold thin films. Journal of Vacuum Science and Technology. B 9, 3329. https://doi.org/10.1116/1.585336

Song, X., Liu, H., Fang, Y., Zhao, C., Qu, Z., Wang, Q., Tu, L.-C. (2020). An Integrated Gold-Film Temperature Sensor for In Situ Temperature Measurement of a High-Precision MEMS Accelerometer. Sensors 20, 3652. https://doi.org/10.3390/s20133652

Yuan, L., Wang, Q., Tang, F., Li, B., Ming, P., Zhang, C. (2022). An enhanced thin-film resistance temperature detector and its application for catalyst layer surface temperature measurement inside PEMFC. eTransportation pp.100178. https://www.sciencedirect.com/science/article/pii/S2590116822000248

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.