Meat processing waste can provide solutions for sustainable agriculture and crop production, whilst valorizing the waste stream from slaughterhouses in a circular process. A new study published online in Sustainability has demonstrated the results of using meat and bone meal as soil nutrients in a multi-year agricultural study.

Study: Meat Processing Waste as a Source of Nutrients and Its Effect on the Physicochemical Properties of Soil. Image Credit: maxbelchenko/Shutterstock.com

Sustainable Agriculture

Sustainable agriculture relies on the rational management of nutrients for crop production. Because nitrogen production is an energy-intensive process, sustainable crop production processes make use of mostly natural sources of this important nutrient. Additionally, in sustainable agriculture, the nutrient balance and natural nutrient cycles must be balanced properly, and the use of external inputs minimized. Moreover, because widely used chemical fertilizers easily leach into ecosystems, sustainable practices must avoid their use as much as possible, if not entirely.

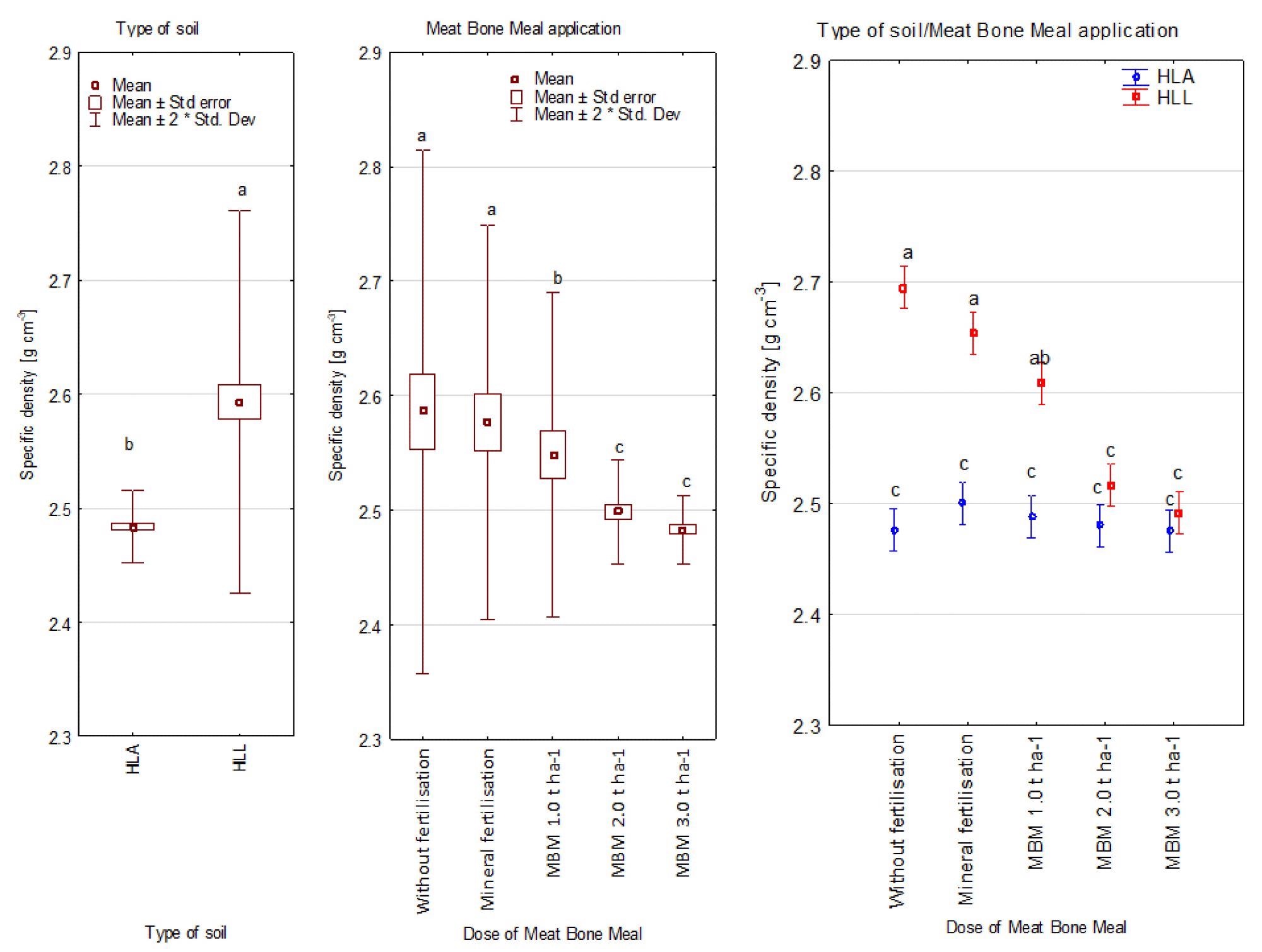

Specific density of soil depending on soil type, meat and bone meal application, soil type/meat and bone meal application, g cm−3. a,b,c—statistically homogenous groups (Tukey’s test); HLA—Haplic Luvisol Arenic soil; HLL—Haplic Luvisol Loamic soil. Image Credit: Stępień, A et al., Sustainability

Aside from nitrogen, another essential nutrient for crop growth is phosphorous. The main natural source of phosphorous is phosphate rock, but this resource is becoming quickly depleted and may run out entirely in the coming decades. Studies have found that 37% of phosphorous derived from human and animal waste would meet the total phosphorous demand of corn production in the USA. Corn is a staple crop that feeds a significant proportion of the world’s population.

Organic farms use manure as a more sustainable alternative to synthetic fertilizers. Organic materials such as manure are an important source of micronutrients such as nitrogen, phosphorous, zinc, copper, and manganese. Crop yields are comparable when using manure or synthetic fertilizer. In farms that only produce crops, alternatives to manure are being explored. Waste animal by-products such as meat and bone meal are a viable alternative.

Using Meat and Bone Meal

Meat and bone meal has similar organic content to manure but contains more nitrogen and phosphorous, whilst containing less magnesium and potassium. The nutrient content of processed animal waste depends upon its origin.

Animal by-products are produced by slaughterhouses. It used to be used as high-protein animal feed until it was banned in the EU in response to outbreaks of Bovine Spongiform Encephalopathy (BSE.) According to EU regulations, class 2 and 3 animal by-products can be used as a soil amendment, whereas class 1 animal by-products must be incinerated.

Meat and bone meal is a slow-release organic fertilizer. Biophysiochemical processes convert the nutrients in these animal by-products into minerals that can be absorbed by plant root systems. The mineralization process depends on several different factors such as the soil’s C/N ratio, temperature, the presence of micro-organisms, and physical and chemical properties. Supplemental fertilization may be required due to the small amounts of micronutrients supplied. Heavy metal contamination of soils does not occur when using meat and bone meal as a fertilizer.

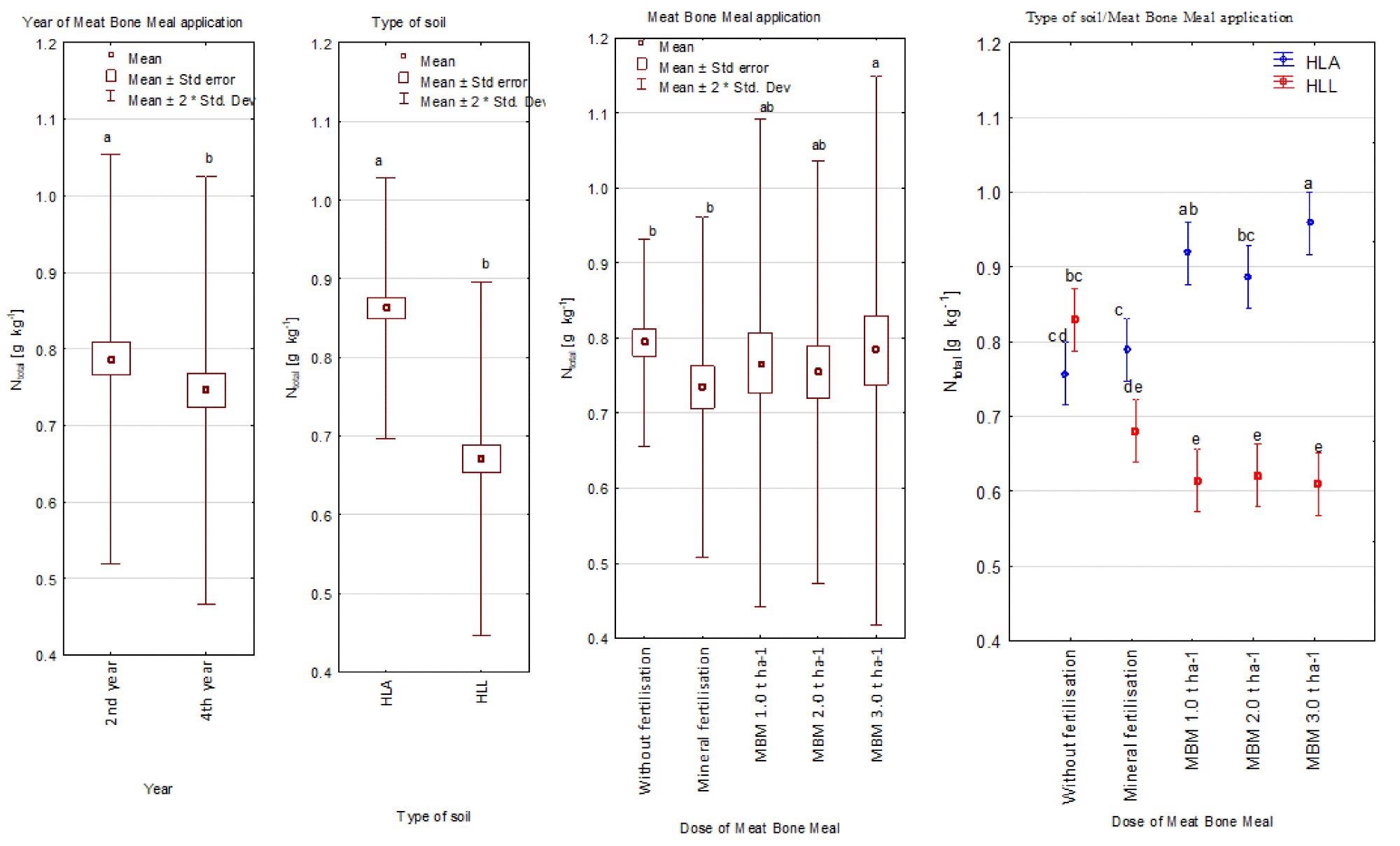

Concentration of total nitrogen in the soil depending on the year of meat and bone meal application, soil type meat and bone meal application, soil type/meat and bone meal application, g kg−1. a,b,c,d,e—statistically homogenous groups (Tukey’s test); HLA—Haplic Luvisol Arenic soil; HLL—Haplic Luvisol Loamic soil. Image Credit: Stępień, A et al., Sustainability

The Study

The objective of the study in Sustainability is to test the effects of meat and bone meal as a fertilizer for maize (corn) crops. Two types of soil, Haplic Luvisol Loamic, and Haplic Luvisol Arenic were studied for their effect on their physiochemical properties. The study was performed between 2014-2017. This was a short-term small-area field experiment using maize monocultures fertilized with the meat and bone meal at different concentrations applied during presowing each year.

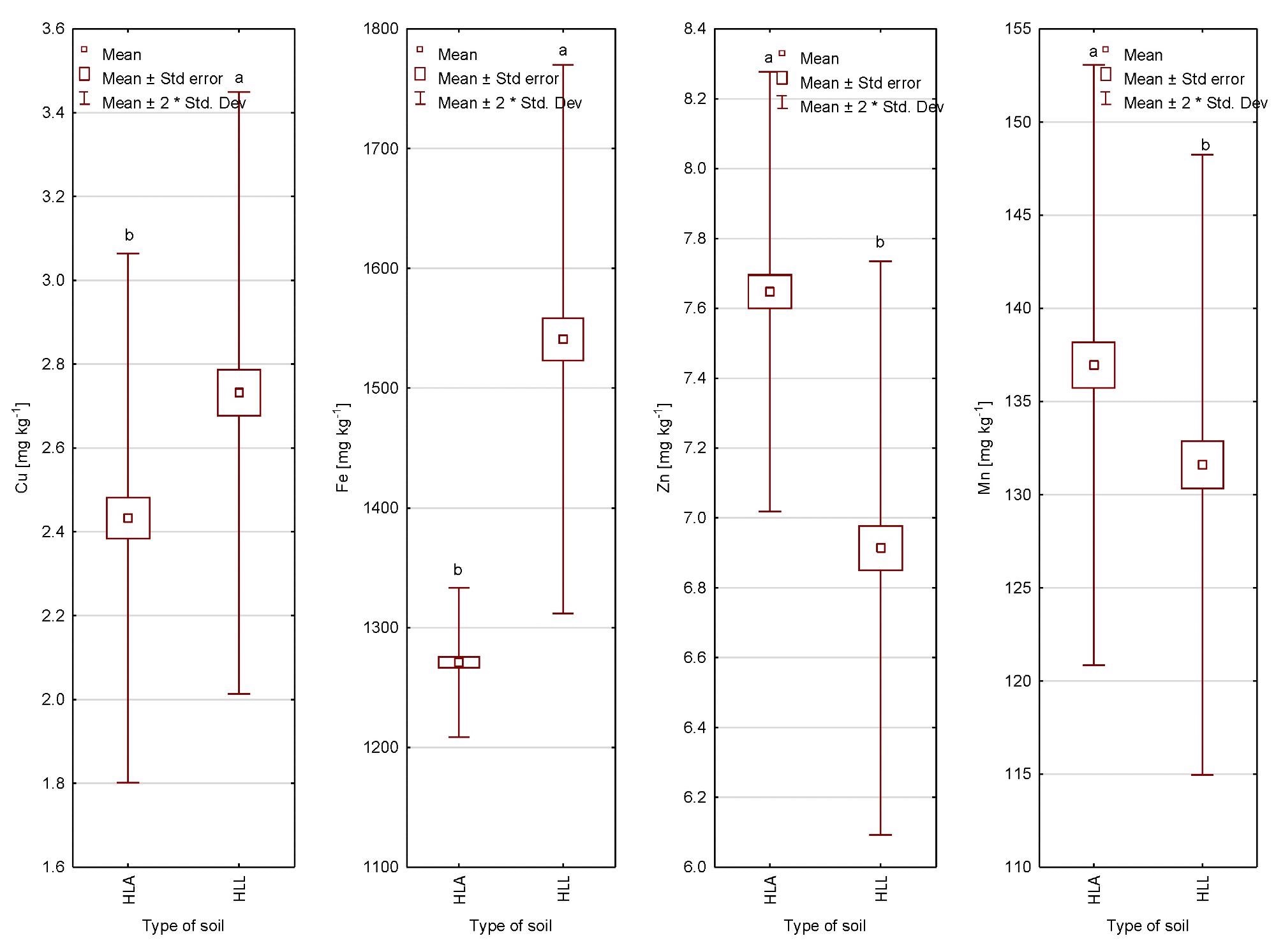

Concentrations of Cu, Fe, Zn and Mn in soil depend on soil type, mg kg−1. a,b—statistically homogenous groups (Tukey’s test). Image Credit: Stępień, A et al., Sustainability

The study demonstrated some positive experimental results. In the Haptic Luvisol Loamic soil, bulk density and specific density decreased and pH increased when meat and bone meal was applied. In Haptic Luvisol Arenic soil, the nitrogen content was highest when meat and bone meal was applied at a concentration of 2.0 t ha-1 and at 3.0 t-1 in Haptic Luvisol Loamic soil. High nitrogen utilization by maize plants accounted for minor differences between untreated and treated soils.

Additionally, increased phosphorous content in soil was observed when the meat and bone meal dose was increased. In Haptic Luvisol Arenic soil, the content of the arable soil layer was lower than Haptic Luvisol Loamic soil, which was caused by higher phosphorous uptake by the plants. In the final year of the study, the highest maize yield was achieved. This was due to the highest dose of meat and bone meal as well as the effect of residual fertilizer in the soil.

Meat and bone meal contains an abundance of micronutrients, and when supplemented with other nutrients, these micronutrients are sufficient to meet the needs of crops. However, the authors have stated that the levels are not high enough for adequate soil enrichment (facilitating the need to re-fertilize soil regularly.) The research published in Sustainability has provided an insight into the potential of using animal by-products for sustainable agricultural practices.

Further Reading

Stępień, A et al. (2022) Meat Processing Waste as a Source of Nutrients and Its Effect on the Physicochemical Properties of Soil [online] Sustainability 14(3) 1341 | mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/3/1341/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.