Materials with auxetic properties are a current research focus in the textiles industry due to their physical properties that make them useful for a variety of purposes. A paper published in the journal Polymers has explored the creation of novel, multi-functional materials from conventional compound fabrics by using traditional textile technologies and laser cutting.

Study: In-Plane Deformation Behavior and the Open Area of Rotating Squares in an Auxetic Compound Fabric. Image Credit: dkHDvideo/Shutterstock.com

Auxetic Materials

When stretched, auxetic materials tend to expand rather than contract, which gives them a multitude of functional uses. Auxetic materials possess a negative Poisson’s ratio, and their auxetic properties are a result of their unique structure, which when stretched resembles a honeycomb shape. A research focus in the textile industry is the creation of materials with auxetic properties at the fiber, yarn, and fabric levels.

At the yarn and fabric levels, auxetic materials can be produced in two ways. Either the yarn/fabric can be produced with induced auxetic geometry using standard fibers and yarns during the production process (for example, spinning, weaving, or knitting) or by using fibers that themselves possess auxetic properties.

The first laboratory attempt to create materials with auxetic properties was conducted in the early 1990s by Alderson & Evans. In this attempt, ultra-high molecular weight polyethylene was produced, which had a Poisson’s ratio of -1.2. This auxetic polymer was composed of a network of rectangular nodes connected by freely hinged, inextensible fibrils/rods in a microporous node-fibril structure. The material was produced using a three-stage thermal process.

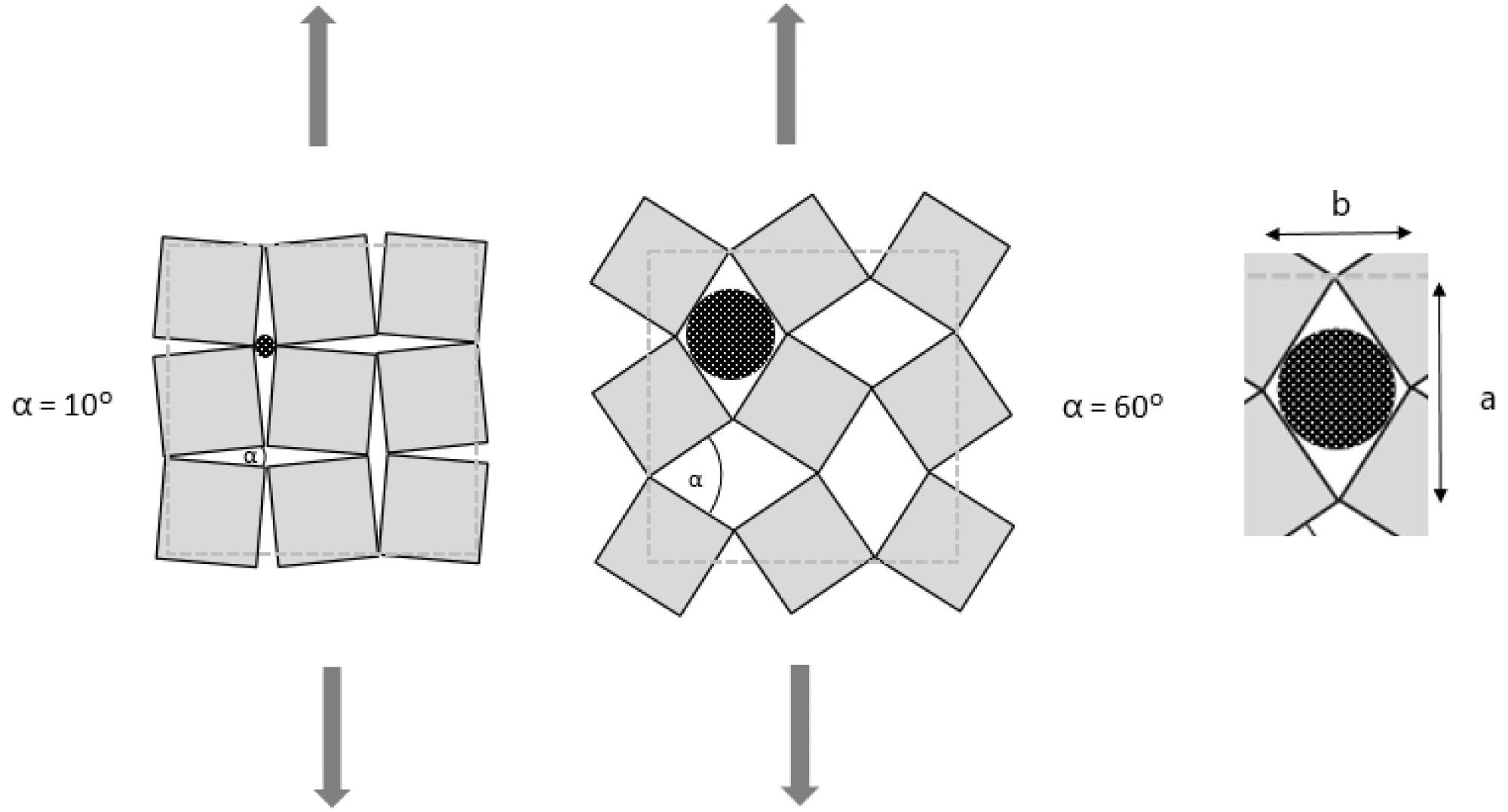

Deformation of fabric with rotating square unit cells geometry under loading (dashed lines–the initial size of the specimen) with particles of different sizes going through the fabric’s open area depending on the applied tension force (a and b are rhombus diagonals). Image Credit: Dubrovski, P.D et al., Polymers

Since the initial experiments, there has been a growing body of studies on manufacturing varied materials with auxetic properties. Anderson et al. used a modified industrial scale conventional melt spinning technique to produce auxetic polypropylene and polyethylene. In 2002, Ravirala et al. produced auxetic polyamide and polyester fibers by modifying an earlier auxetic polypropylene fiber fabrication method. He et al. in 2005 produced auxetic liquid crystalline polymers.

Work in the last decade by Hook, Sloan, Ge, and Ng, amongst others, has developed and improved helical auxetic yarns (HAY.) These auxetic materials consist of a thick yarn core and finer, stiffer helically wound wrap yarn which under tension starts to uncurl, with the core yarn moving laterally. This increases the width of the yarn and achieves the negative Poisson’s ratio characteristic of auxetic materials. The auxetic yarn undergoes a resulting lateral extension.

Producing Low-Cost Auxetic Fibers Using Conventional Fibers and Yarn

Another way to produce low-cost auxetic fibers is to manufacture auxetic fabrics using conventional fibers and yarn. By inducing a unique fabric structure, a multi-functional auxetic material can be manufactured. Numerous studies have been published which have developed these low-cost auxetic fabrics.

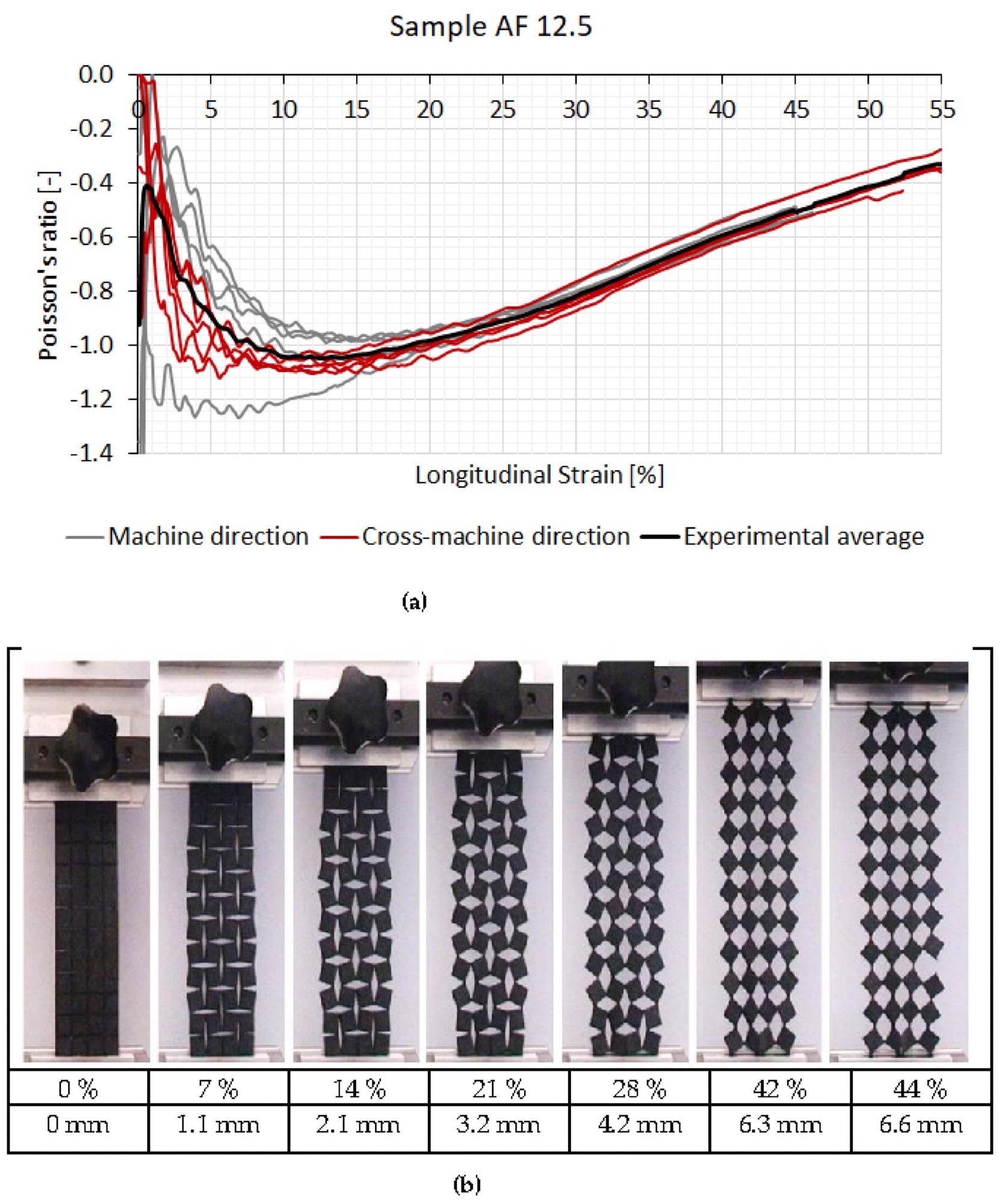

Poisson’s ratio of the AF 12.5 sample with the longitudinal strain (a) and corresponding fabric deformation in the machine-direction (b) (LS–longitudinal strain (%), LD–longitudinal displacement (mm)). Image Credit: Dubrovski, P.D et al., Polymers

Foldable geometry and re-entrant geometry have been utilized in studies to develop novel knitted and woven fabrics that display in-plane auxetic behavior. In 2011, Hu et al. created auxetic weft-knitted fabrics which had rotating rectangles using rotating unit geometry. Partial interlock knitting was used to form the rectangle units which were connected in the wale direction by using a binding-off technique with elastic yarn.

The rotating rigid unit cell geometry was first proposed by Grima et al. in the early 2000s. This geometry connects units (squares, rectangles, and triangles) with corner hinges. Further rotating rigid units (parallelograms and rhombi) were investigated by Grima et al. to create auxetic fabrics.

The Study

The study published in Polymers has expanded on the author’s previous work investigating modified conventional non-woven fabrics with rotating rigid cell geometry and auxetic behavior. The authors discovered that non-woven samples which had smaller cell sizes possessed the highest negative Poisson’s ratio, making them highly auxetic.

The presented research deals with the auxetic behavior of fabrics but focuses on compound fabrics and on the open area during tensile loading as the consequence of cell rotation. To the authors’ knowledge, the development of auxetic compound fabrics is missing from current literature. Additionally, no current studies have attempted to turn a conventional compound fabric into an auxetic fabric. Compound fabrics behave differently under tensile forces than non-compound fabrics; additionally, they have a more complex structure.

Moreover, whilst rotating cell geometry has been extensively investigated, it has not been as widely studied on textile substrates, especially compound fabrics. The goal of the study was to create a novel auxetic material that could be used as a novel filtration material that has an adjustable open area that could be used to filter multiple particles.

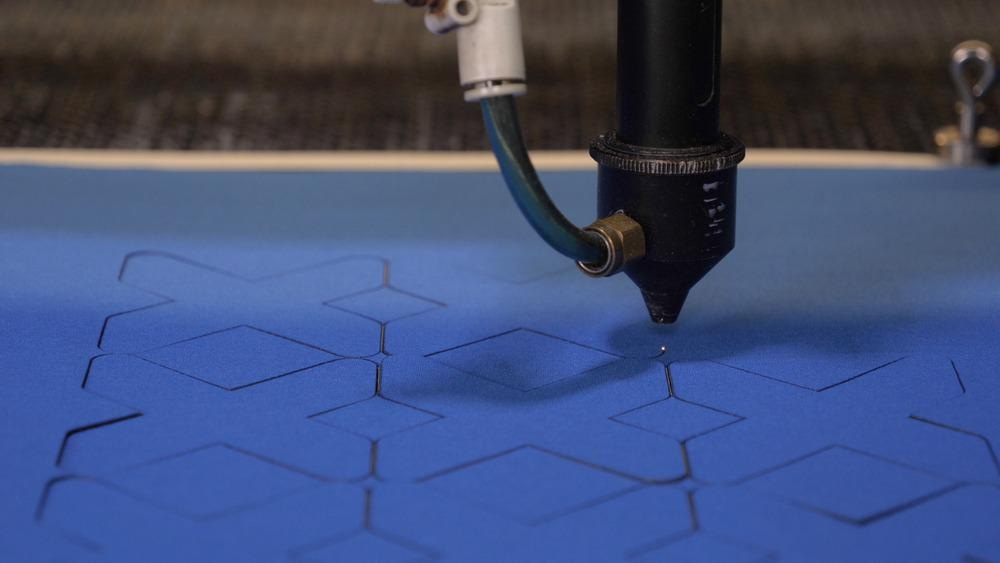

In the research, conventional compound fabric, for example woven fabric-reinforced needle-punched non-woven fabric, was cut with a laser to form rotating square structures and induce auxetic behavior in the compound material. The authors analyzed and discussed properties such as the material’s Poisson ratio, in-plane deformation behavior under tensile load, and the relationship between the applied force and the fabric’s open area.

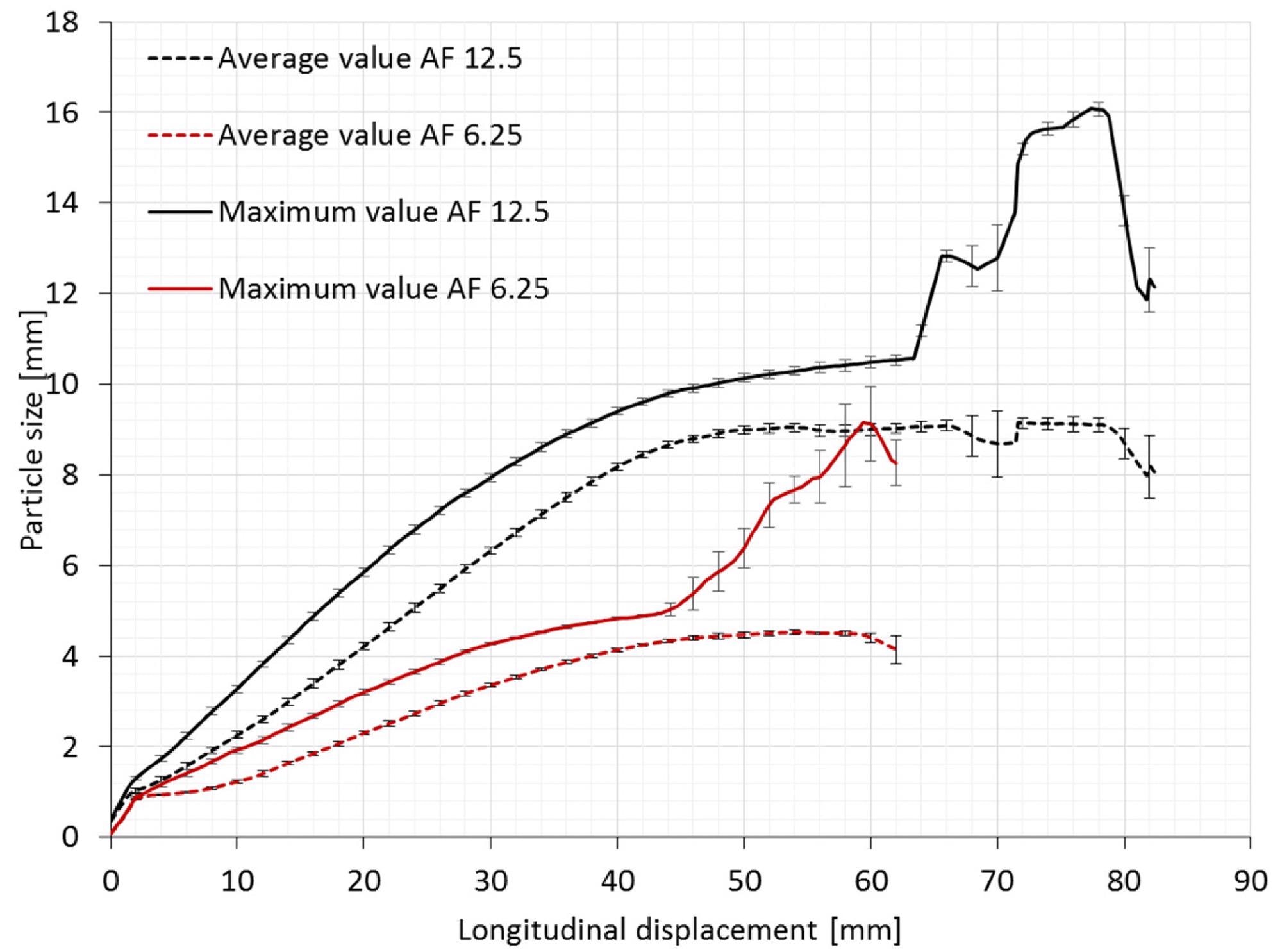

The relationship between the particle sizes and longitudinal displacement. Image Credit: Dubrovski, P.D et al., Polymers

The authors concluded that larger unit cells in the fabric exhibited higher average negative Poisson’s ratio, a major tensile strength reduction due to the introduction of auxetic geometry which limits their application to low tensile loads, and a higher particle size range for filtering depending on tension load related to a larger unit cell size in compound auxetic fabrics.

Finally, the authors have stated that future research will focus on the parametric study of geometric parameters and how they influence the material’s deformation and mechanical behavior, as well as considering different rotating unit structure patterns.

Further Reading

Dubrovski, P.D et al. (2022) In-Plane Deformation Behavior and the Open Area of Rotating Squares in an Auxetic Compound Fabric [online] Polymers 14(3) 571 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/3/571

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.