In a recent study published in the journal Frontiers in Materials, researchers from Sweden investigated the sensitivity of products made of super duplex stainless steel (SDSS) with unified number system (UNS) code SDSS UNS S32750 under test conditions identical to natural environments and with no simulated thermal aging.

Study: Fatigue behavior of super duplex stainless steel exposed in natural seawater under cathodic protection. Image Credit: Maxx-Studio/Shutterstock.com

Super Duplex Stainless Steels

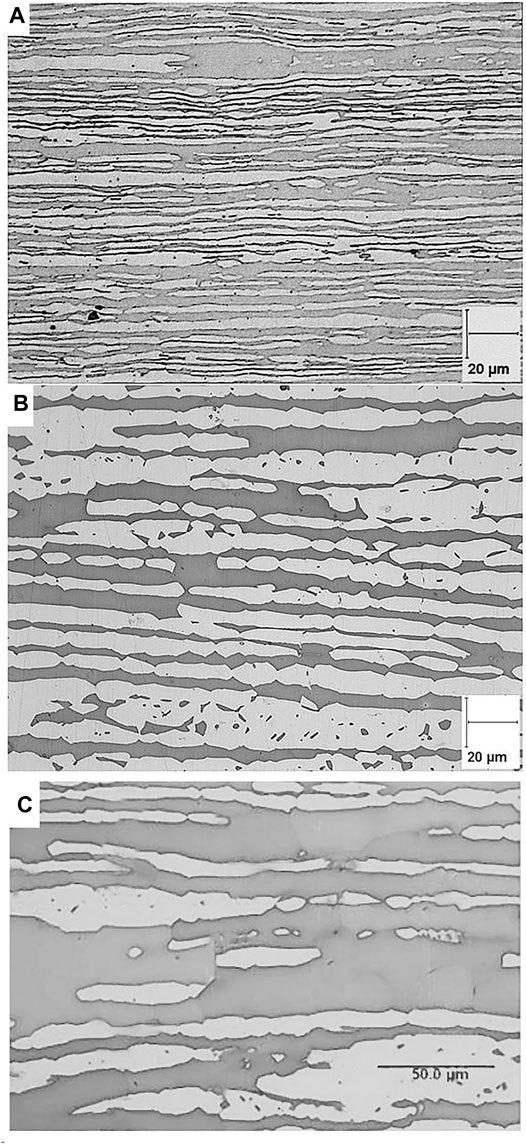

Super duplex stainless steels (SDSSs) are used in offshore functions and have a significant toughness, strength, and corrosion resistance. The microstructure of SDSS consists of a mixture of ferrite and austenite in equal amounts. For offshore applications, SDSSs are frequently mixed with carbon steel, due to which they are subjected to cathodic protection (CP). CP may also be used to protect SDSS when the operating temperature is higher than the maximum allowed temperature for using the alloys in seawater.

Microstructure of UNS 32750 SDSS alloys (A) thin tube SDSS 1, (B) thin plate SDSS 2, and (C) thick plate SDSS 3. Ferrite phase appears in dark gray and austenite phase in light gray. Image Credit: Vucko, F et al., Frontiers in Materials

A slight reduction in SDSS corrosion potential is beneficial as it reduces the risks of stainless-steel passivity breakdown and the formation of anodic sites, such as crevices. However, several failures in subsea applications have been reported due to cathodic protection, which finally results in hydrogen-induced stress cracking (HISC).

The present study aimed to examine the fatigue behavior of SDSS UNS S32750 in seawater with and without CP. They also determined the impact of grain size, surface defects, load ratio, temperature, and frequency on the steel’s fatigue life and material behavior. Additionally, researchers also examined the changes in the microstructure of the material when manufactured through orbital welding.

Methodology

Three SDDS samples with different austenite spacing were selected for the study. The selection process of samples was based on a line intercept method derived from the standard metallurgical practice. The first sample was SDSS 1 and SDSS 4 tubes with highly low austenite spacing. The second was SDSS 2 thin plates with intermediate austenite spacing, and the third was SDSS 3 thick plates with larger austenite spacing.

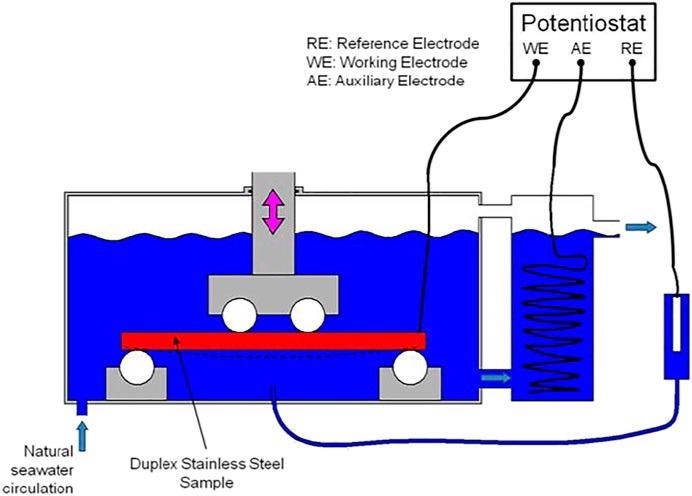

In the study, four-point bending was used to perform the in situ fatigue tests, and the experiments were performed with and without CP. Additional tests were carried out at a temperature of 80±1°C, and one fatigue curve was plotted using 12 samples.

The researchers developed a titanium tank to perform fatigue experiments under the seawater. The tanks’ counter electrode was made of titanium mixed metal oxide (TiMMO) and was placed outside the tank to avoid chlorination. Natural seawater from the Bay of Brest was used to fill the tank, and seawater circulation was performed to renew the tanks’ total volume. Additionally, the biological activity of natural seawater was also maintained during the experiments.

The researchers tested the specimens with no additional surface preparation, but machining treatment was performed to control the notches’ shape. They performed thermal desorption analysis (TDA) for hydrogen quantification, and a scanning electron microscope was used to examine the fracture surfaces and cross-sections after fatigue testing. TDA was used to measure hydrogen quantification after pre-charging SDSS samples for 1 to 30 days at temperatures of 20°C and 80°C.

As the mechanical strength of alloys reduces with an increase in temperature, the strength amplitude was normalized during the calculations to get accurate results.

Equipment to perform the 4-point bending fatigue test in natural seawater with CP. Image Credit: Vucko, F et al., Frontiers in Materials

Results

The results indicate that the hydrogen content increased with charging time but stabilized at certain stages during the experiment.

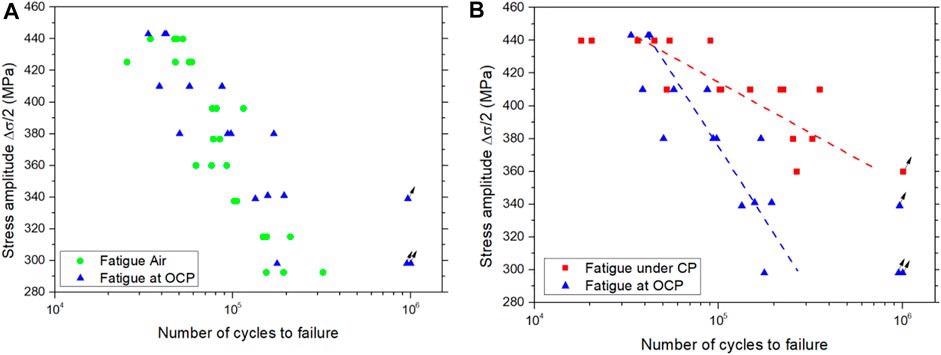

For fatigue tests with and without CP, the results demonstrated that immersion in seawater did not affect fatigue performance. Additionally, these findings were similar to previous studies conducted on fatigue performance.

The experiments conducted to identify the influence of test temperature indicated that the fatigue life reduced at 80°C when compared with results at 20°C. SDSS 3 with larger austenite content had the least fatigue resistance, whereas SDSS 1 and 2 with larger austenite spacing had similar results.

The fatigue performance of the specimens tested under CP was unaffected by stress concentration. However, fatigue performance under CP was higher than open circuit potential (OCP) at equivalent notch depth, which indicates that the hydrogen addition has had a significant impact on the fatigue performance of SDSS.

The fatigue performance of welded specimens was lower than that of samples tested without the orbital weld. The fatigue life of welded specimens was higher under CP than the OCP. Additionally, the failure occurred systematically at the weld toe in all the samples tested due to microstructural modifications and stress concentration.

Comparison of the fatigue lives of SDSS 1 (A) in air and in natural seawater at OCP and (B) at OCP and under CP at −1,100 mV/SCE. Runouts (>1M cycles) are indicated by arrows. Image Credit: Vucko, F et al., Frontiers in Materials

Conclusions

The study evaluated the fatigue performance of UNS S32750 stainless steel in air and natural seawater with and without CP. The results indicate that the SDSS is resistant to hydrogen embrittlement, but critical engineering examination is required for reliable offshore applications.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Vucko, F., Ringot, G., Thierry, D., & Larché, N. Fatigue behavior of super duplex stainless steel exposed in natural seawater under cathodic protection. Frontiers in Materials, 26. https://www.frontiersin.org/articles/10.3389/fmats.2022.826189/full