In an article recently published in the journal Frontiers in Materials, researchers reported the fabrication of a superhydrophobic and eco-friendly coating of aluminum oxide/polydimethylsiloxane (Al2O3@PDMS) composite with mechanical robustness using PDMS, Al2O3 nanoparticles (NPs), and a spray coating method.

Study: Eco-Friendly Anticorrosion Superhydrophobic Al2O3@PDMS Coating With Salt Deliquescence Self-Coalescence Behaviors Under High Atmospheric Humidity. Image Credit: Stock-Asso/Shutterstock.com

The researchers also evaluated the self-coalescence and salt deliquescence characteristics of this robust and superhydrophobic Al2O3@PDMS coating.

Background

Because of their weldability, high specific strength, low cost, and machinability, carbon steels are frequently employed in structural applications in industrial and engineering structures. The aggressive character of various service environments, however, causes severe corrosion and deterioration of exposed carbon steels, resulting in significant financial losses and unavoidable safety mishaps.

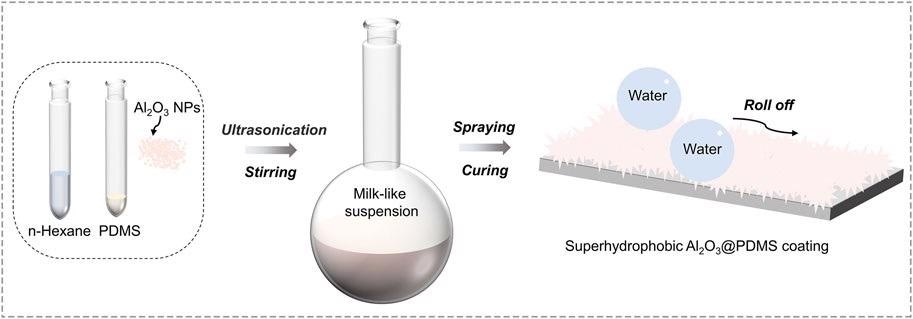

Schematic illustration of the preparation procedure of the superhydrophobic Al2O3@PDMS composite coating. Image Credit: Zhang, B et al., Frontiers in Materials

According to extensive research, one of the most efficient ways for minimizing the likelihood of metallic corrosion is to apply multifunctional protective coatings. Since it can act as a non-wetting physical barrier between the surrounding environments and the metallic surface, the production of bio-inspired superhydrophobic coatings has become a significant topic in the anticorrosion research field in recent years.

A surface having a sliding angle less than 10° and a stable water contact angle of more than 150° is known to have nature-inspired superhydrophobicity. The two most important requirements for creating superhydrophobic materials are micro/nano/binary rough features and low surface energy.

Many processes have been used to create superhydrophobic surfaces; however, despite tremendous progress in the scientific community, there are still several restrictions in large-scale production and extensive practical applications of superhydrophobic materials. Given these challenges, designing and developing simple, low-cost, eco-friendly superhydrophobic coatings without the use of fluorine-based chemicals for effective anti-corrosion applications is very important.

About the Study

In the present study, Al2O3 NPs and PDMS with intrinsic hydrophobicity were used to design and produce a superhydrophobic Al2O3@PDMS composite coating utilizing a simple one-step fluorine-free spray coating approach. The evolution of surface wettability was studied with varying Al2O3 NPs/PDMS mass ratios (1:2, 1:4, 3:4, 1:1, 3.2, and 5:4).

Subsequently, chemical compositions, surface morphologies, NaCl salt deliquescence behaviors, anti-corrosion characteristics, dynamic water droplet contacting process, and mechanical stability of the Al2O3@PDMS composite coating were all examined in depth by using XPS, EDS, FESEM, electrochemical impendence spectroscopy, potentiodynamic polarization, and contact angle meter techniques.

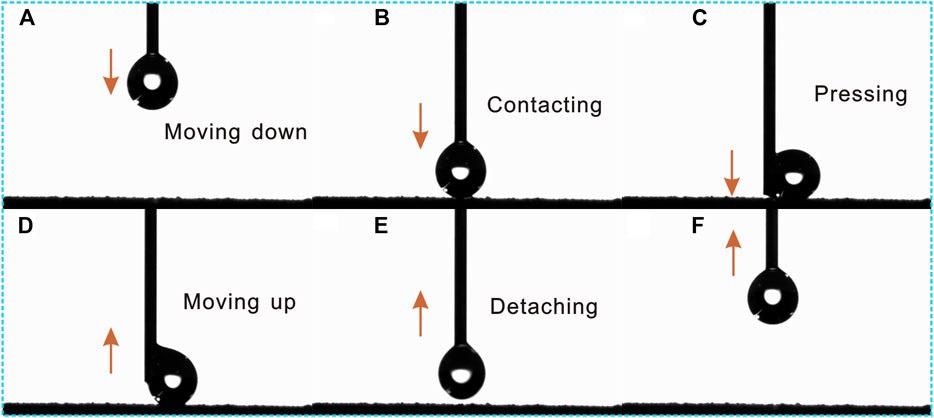

(A–F) Dynamic contacting process of water droplet on the as-prepared superhydrophobic Al2O3@PDMS composite coating. Image Credit: Zhang, B et al., Frontiers in Materials

The electrochemical measurements were performed to assess the corrosion resistance capacity of the superhydrophobic Al2O3@PDMS coating in comparison to the bare Q235 carbon steel. Furthermore, under high atmospheric humidity, the deliquescence behaviors of the NaCl salt particles as well as their instantaneous self-coalescence phenomenon on the as-grown Al2O3@PDMS coating were elucidated.

Observations

In this study, the researchers observed that for producing superhydrophobic Al2O3@PDMS composite coatings, a mass ratio of 5:4 (Al2O3/PDMS) was optimum. The adhesive force between the solid surface and the water droplet was found to be incredibly low in the as-grown superhydrophobic coating.

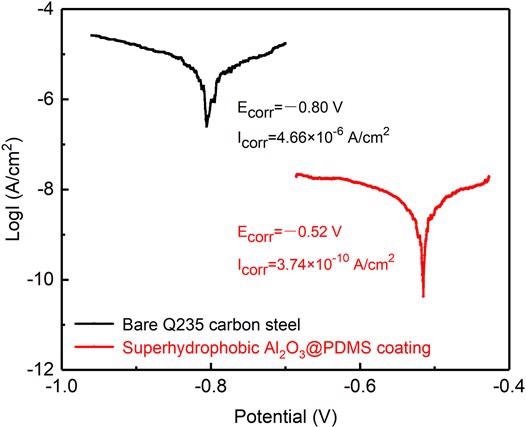

The superhydrophobic Al2O3@PDMS coating had a |Z|0.01 Hz value of 1.53 x 107Ω.cm2, which is higher by four orders of magnitude compared to bare Q235 carbon steel, having |Z|0.01 Hz value of 1.31 x 103 Ω.cm2. This demonstrated the exceptional corrosion prevention characteristics of the Al2O3@PDMS coating. Furthermore, the superhydrophobic Al2O3@PDMS coating's Ecorr changed by 0.27 V in the positive direction, and the reduction in the magnitude of Icorr was found to be more than four orders.

The deliquescence behaviors of single and double NaCl salt particles over the as-prepared superhydrophobic Al2O3@PDMS coating demonstrated instantaneous self-coalescence and spherical saline droplets. This showed that the superhydrophobic surface's Cassie–Baxter interfacial phase contacts could act as an efficient barrier to repress atmospheric corrosion in industrial and marine environments with high relative humidity.

Potentiodynamic polarization curves of the bare Q235 carbon steel and the as-prepared superhydrophobic Al2O3@PDMS coating with a scanning rate of 0.167 mV/s. Image Credit: Zhang, B et al., Frontiers in Materials

Conclusions

In conclusion, a simple one-step substrate-independent spray coating technique was used to create an environmentally-friendly and resilient superhydrophobic Al2O3@PDMS coating without the utilization of hazardous fluorochemicals. The micro-/nano-roughness caused by Al2O3 NPs and the low surface energy of PDMS both contribute to the generation of water-repellent superhydrophobicity.

The superhydrophobic Al2O3@PDMS coating's |Z|0.01 Hz and Rct values were found to be four orders of magnitude greater than that of the bare Q235 carbon steel, according to the electrochemical studies. This indicates that the substrate-independent superhydrophobic Al2O3@PDMS composite coating has outstanding adaptability and corrosion suppression capabilities.

The instantaneous self-coalescence and deliquescence behaviors of NaCl salt particles were observed on the Al2O3@PDMS coating. This implied that the superhydrophobic surface could act as an effective barrier in order to prevent the formation of saline liquid thin films and protect the underlying substrate from corrosion.

Overall, the researchers believe that this tough and superhydrophobic Al2O3@PDMS coating should be easy to apply to a range of substrates and will find applications in self-cleaning, liquid repellency, corrosion resistance as well as other areas.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Zhang, B., Yan, J., Xu, W., et al. Eco-Friendly Anticorrosion Superhydrophobic Al2O3@PDMS Coating With Salt Deliquescence Self-Coalescence Behaviors Under High Atmospheric Humidity. Frontiers in Materials 9 (2022). https://www.frontiersin.org/articles/10.3389/fmats.2022.839948/full