Lubricants are vital for industry as they reduce friction and wear in machine parts. However, their manufacture is currently unsustainable, with research into green alternatives in recent years seeking to address this issue. A paper published in the journal Molecules has explored the production of sustainable lubricants from microalgae.

Study: Microalgae Biomass as a New Potential Source of Sustainable Green Lubricants. Image Credit: Perception7/Shutterstock.com

Lubricants

Lubricants can either be solid, liquid, semi-solid, or gaseous in form. In essence, they form layers between two surfaces to separate them and provide some degree of protection. Using a lubricant facilitates the smooth operation of machinery parts and reduces the risk of failure, whilst also contributing to cost and energy savings. Moreover, lubricant quality is a determining factor in the performance and energy consumption of industrial parts and processes.

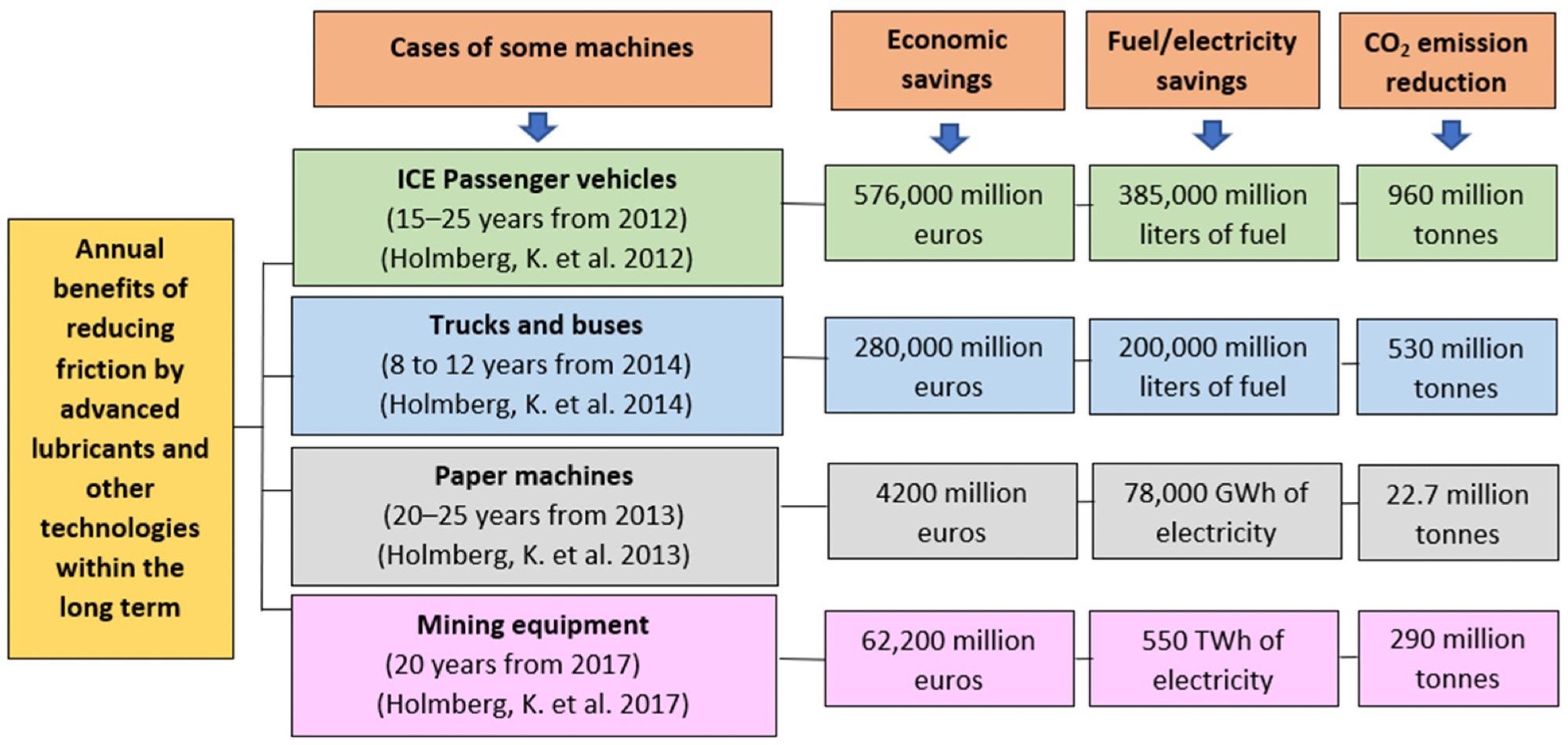

Annual global economic and energy savings, and CO2 emissions reduction by reducing friction in different industrial sectors. Image Credit: Farfan-Cabrera, L.I et al., Molecules

The service life of parts and machinery can be significantly improved by the selection of proper lubricants, and studies have demonstrated that reducing friction losses and using advanced lubricants and enhanced technologies can reduce the CO2 emissions of industrial processes.

However, most lubricants are produced from oil, coal, and natural gas, which presents problems with sustainability and eco-friendliness in their manufacture and use. Increasing costs of crude oil alongside the depletion of natural reserves and the carbon emissions produced during processing have increased interest in renewable, sustainable, non-toxic, and net-zero carbon-emitting green lubricants.

Lubricant Requirements

There are several requirements for a high-performance lubricant, depending on the industrial application. These include high thermal, oxidation, and hydrolytic stability, superior tribological behavior, corrosion inhibition, high boiling point, high viscosity, and a low pour point.

Conventional lubricants are formulated to meet the demands of industry and possess favorable properties. The two common types of lubricants are mineral oils and synthetic oils. Mineral oils are liquid mixtures of hydrocarbons that are obtained via different refining and distillation processes from crude oil, whereas synthetic oils are obtained by chemically modifying crude oil. Synthetic oils possess enhanced chemical and thermal properties compared to mineral oils and therefore are the preferred choice for demanding contemporary applications.

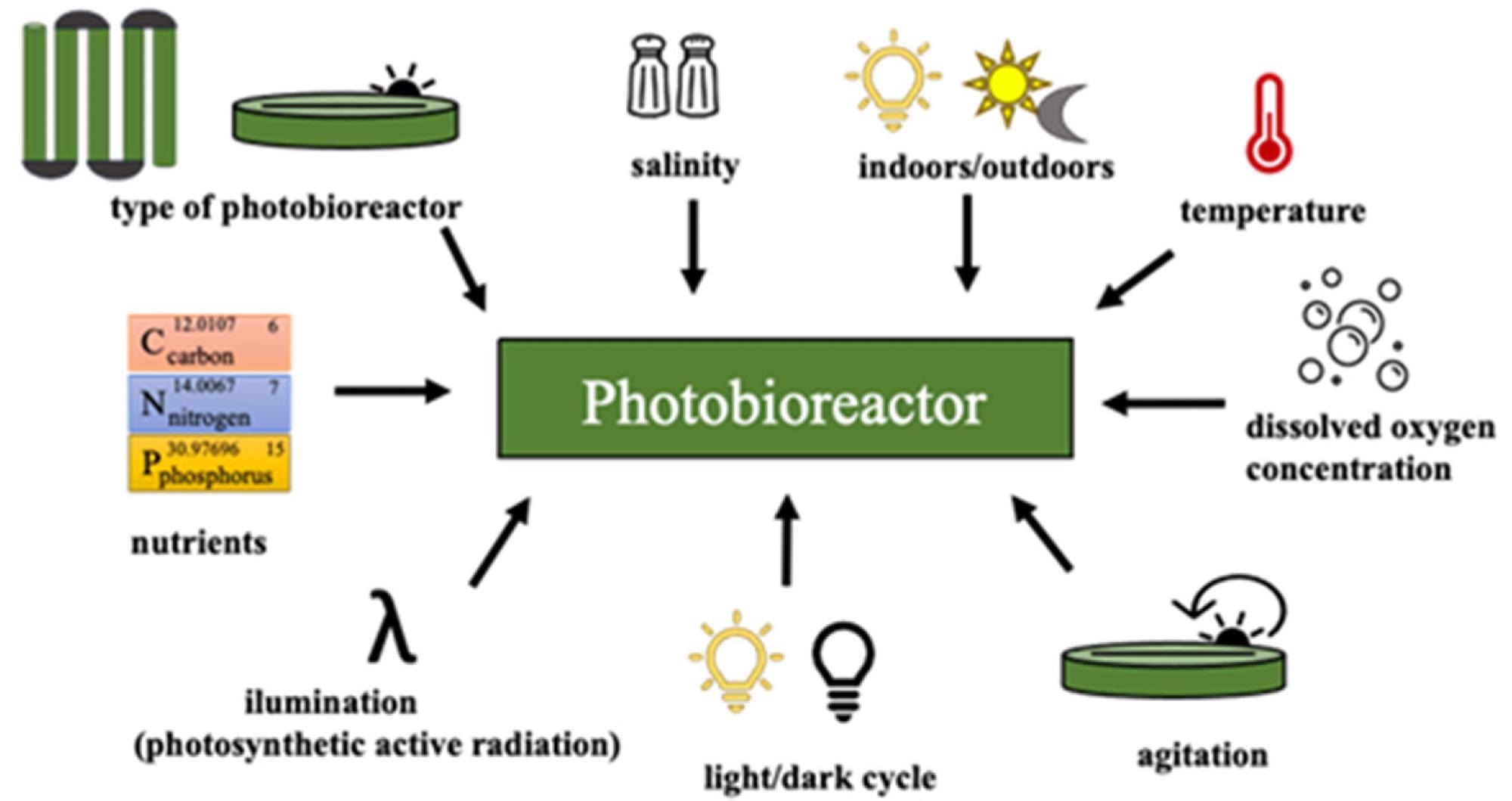

Schematic representation of the main variables in cultivation of microalgae biomass. Image Credit: Farfan-Cabrera, L.I et al., Molecules

The Environmental Damage Caused by Conventional Lubricants

Despite their superior properties and their essential applications for industry, the production and use of lubricants have been linked with significant environmental damage. Additionally, the production, use, and disposal of these materials can cause harm to the health of individuals handling them. For this reason, several governments have introduced regulations that govern the entire life cycle of lubricants, covering toxicity, safety, handling, and their safe disposal.

According to some sources, 50% of the total lubricants produced and used globally end up in the environment via evaporation and spillages. Formal disposal methods are complicated and challenging, and the production and disposal of lubricants cause greenhouse gas emissions, contributing to anthropogenic climate change.

To address this, green lubricants have been widely proposed, investigated, and developed by scientists across the world. These lubricants have higher biodegradation rates than conventional mineral and synthetic oils and are sourced from biomass such as vegetable oil. Widely explored and promising sources for green lubricants include coconuts, sunflowers, rapeseed, soybeans, castor oil, as well as inedible crops such as neem and Callophyllum innophylum.

The interest in using vegetable oils is attested to by companies such as Total, ExxonMobil, and Dutch Royal Shell producing and marketing bio-lubricants. Despite their eco-friendliness, safety, and non-toxicity, however, the production of green lubricants from vegetable oil is problematic from the standpoint of land and crop usage. One approach which can lessen this impact is to use vegetable oil-based lubricants as additives in conventional lubricants, but this is not an ideal solution.

The Study

An alternative production route for green lubricants has been explored in the new study published in Molecules. Rather than using vegetable oil, which uses up valuable food resources, the team has investigated the use of microalgae biomass to produce ecologically friendly and sustainable bio-lubricants.

As bio-lubricants and biofuels share the same chemical origins (fatty acid esters) existing studies on microalgae-derived biofuels could prove useful for bio-lubricant production. However, as the desired properties for each are different, the research has stated that a variety of chemical treatments are needed to obtain bio-lubricants with the required performance. A second transesterification process or other conversion processes can obtain the required properties.

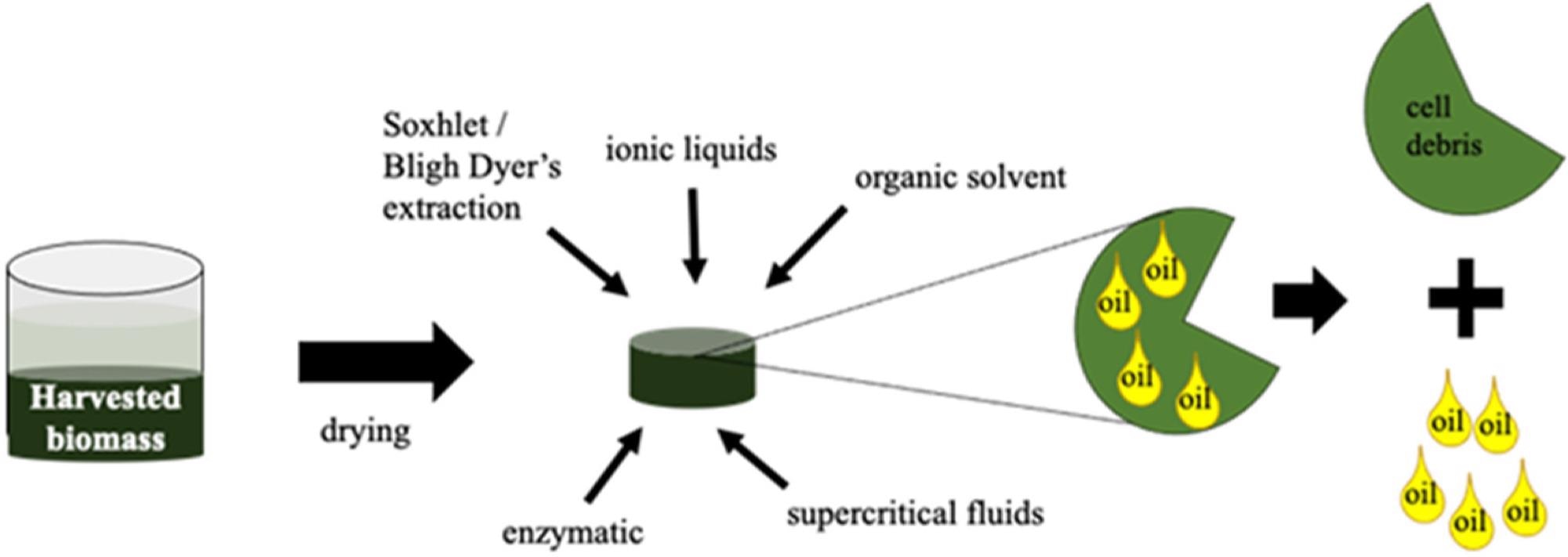

Schematic representation of oil extraction from microalgae biomass. Image Credit: Farfan-Cabrera, L.I et al., Molecules

The review presented in Molecules has four main purposes. Firstly, it reviews and discusses current attempts and progress in technologies for microalgal biorefinery processes and methods of developing bio-lubricants for several industrial processes. Secondly, prospective microalgal strains are identified and examined with respect to their abilities for lipid accumulation, their fatty acid profiles, and their feasibility for industrial-scale production.

Thirdly, the main chemical modifications which enhance the properties of lubricants produced from microalgae are investigated by the authors. Finally, the review has presented a guide for the reader to select appropriate microalgae oils and chemical modifications for further research and development of microalgae bio-lubricants for specific industrial processes. The study makes a significant contribution to the field and can be used as a basis for the future development of sustainable green lubricants.

Further Reading

Farfan-Cabrera, L.I et al. (2022) Microalgae Biomass as a New Potential Source of Sustainable Green Lubricants [online] Molecules 27(4) 1205 | mdpi.com. Available at: https://www.mdpi.com/1420-3049/27/4/1205

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.