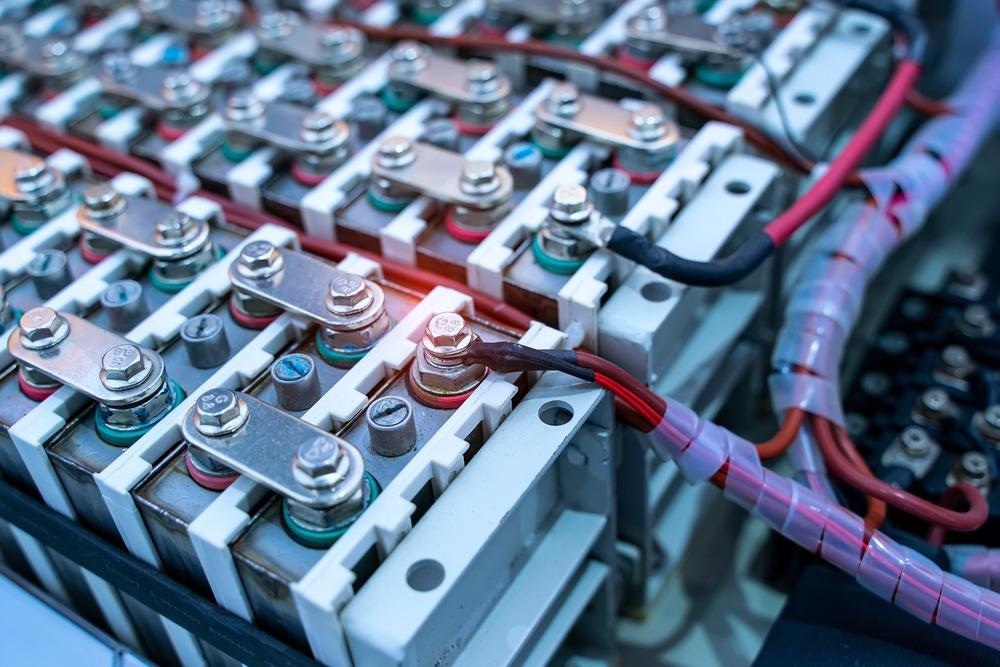

Lithium-ion batteries (LIBs), known for their high energy density, excellent charge storage characteristics, longevity, and high operating voltage, have become the key component of electronic vehicles, portable electronics, and the alternate energy economy.

Image Credit: asharkyu/Shutterstock.com

Exploiting the electrode material of LIBs is the most crucial and feasible technique for enhancing their electrochemical properties. Existing electrode material research has gone beyond traditional carbon-based graphite anodes and toward alternative materials such as tin, transition metal oxides, and silicon-based materials.

Silicon, the most plentiful element on earth’s crust following oxygen, has gained plenty of attention as a favorable anode material owing to its electronic properties, mainly a high capacity.

However, there is a limitation: this material also experiences a very large volume alteration during operation. This impacts its structural integrity, stability, and electrical properties, which leads to issues such as peeling of the current collector or particle breakage during charging and discharging. These problems have prevented silicon-based materials from being commercialized in the LIB sector.

To avoid these issues, Research Fellow Ravi Nandan, Doctoral Course Student Noriyuki Takamori, Technical Specialist Koichi Higashimine, Senior Lecturer Rajashekar Badam, and Prof. Noriyoshi Matsumi of the Japan Advanced Institute of Science and Technology, explored zinc blende for inspiration.

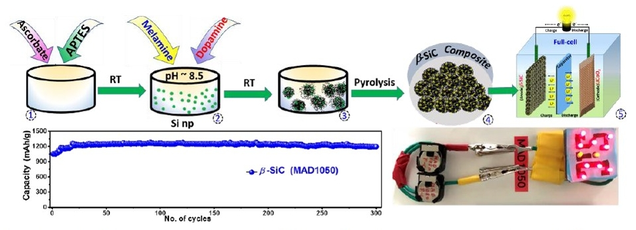

In new research that has appeared in the Journal of Materials Chemistry A, the researchers present an advanced, instrumentation-free, and novel approach for creating exclusive zinc blende silicon carbide nanoparticles that can be carried out at comparatively lower temperatures.

An outline of the proposed methodology for designing silicon carbide, an enduring and effective anode for potential adoption and application in Li+-ion battery. Image Credit: Noriyoshi Matsumi from JAIST

The three-dimensional intermetallic structure of the zinc blende system securely holds lithium ions in its interstitial sites. It also experiences very little volumetric variations when the lithium-ion is traveling between host materials, which guarantees enhanced longevity and reversibility.

The silicon-based equivalent of zinc blende type material is β-silicon carbide (SiC). Earlier studies have described methods for the production of β-SiC composites for anode materials, but most of them entailed complex processes using advanced instruments.

The energy, cost, and consumption associated with conventional β-SiC composite synthesis techniques severely limits its usage. We aimed to develop a user-friendly, easily adaptable, economical, and robust to widen the horizon of β-SiC across laboratories for electrochemical exploration. Without facile preparation methods, it would be difficult to match the literature and scientists’ insights available for other peers like graphite from a LIB application point of view.

Noriyoshi Matsumi, Professor, Japan Advanced Institute of Science and Technology

The researchers formulated a two-step synthesis process for the preparation of the βSiC-based anode material for LIBs. The first step required the creation of silicon nanoparticles in a polydopamine matrix, and the second step was its transformation into the unique variant β-SiC nanoparticles in an N-doped carbon matrix. Remarkably, this transformation requires a lot lower temperature (as low as 600°C) compared to conventional approaches.

The material acquired was then used in anodic half-cell configuration and made to undergo electrochemical screening. The results showed rated capacity, high current density, and favorable compatibility for reversible lithium-ion storage. It also displayed high-capacity retention, around 94% after 300 cycles of charging and discharging to keep discharging capacity of 1195 mAhg-1.

This manufactured material can be effectively used as an anode when integrated with the commercial LiCoO2 as the cathode, and the full cells produced this way support the potential of β-SiC for use in a commercial LIB system. The facile preparation method in this research has paved the way for numerous β-SiC and LIB-related research that were restricted by the availability of materials.

The global carbon emissions due to fossil fuel-powered transportation is increasing by the day. Our low-cost methodology for fabricating highly efficient β-SiC anode materials will allow the development of high-energy density batteries for the cleaner and greener electric automotive industry through use in electric vehicles. In fact, their application can potentially be expanded to even other classes of vehicles such as trains, planes, and ships.

Noriyoshi Matsumi, Professor, Japan Advanced Institute of Science and Technology

Journal Reference:

Nandan, R., et al. (2022) Zinc blende inspired rational design of a β-SiC-based resilient anode material for lithium-ion batteries. Journal of Materials Chemistry A. doi.org/10.1039/d1ta08516f.