Valorizing waste materials is a key strategy for achieving a circular economy. Writing in Sustainability, a team of researchers from Saudi Arabia and Australia has investigated the use of marble waste in road construction.

Study: Experimental Study of the Usability of Recycling Marble Waste as Aggregate for Road Construction. Image Credit: mbrphoto/Shutterstokc.com

Road Construction

The need for infrastructure due to population growth, rapid urbanization, and industrialization across the world has led to the exploitation of vast amounts of virgin resources. Road construction is widespread and uses huge amounts of aggregates and raw materials.

Aside from the exploitation of dwindling resources, constructing roads and pavements emits significant amounts of carbon dioxide and other greenhouse gases. Moreover, the cost of quarrying aggregates and using them for roads is expensive, and the process is environmentally damaging and labor-intensive. Road layer performance is influenced by the aggregates used and their behavior in the material matrix.

Crushing process steps of the marble waste. Image Credit: Benjeddou, O & Mashaan, N et al., Sustainability

Utilizing Industrial Waste as Aggregate Materials

Due to the environmental damage caused by the extraction, processing, and utilization of finite raw materials in road construction, researchers have focused on utilizing industrial waste materials in recent decades. The recycling and reuse of waste materials reduces the demand for raw natural resources, improves sustainability in construction, and reduces the costs associated with extraction and processing.

Industrial waste materials such as fly ash, blast furnace slag, foundry sand, and plastic waste have been investigated thoroughly for use as aggregate materials. Their physical, chemical, and mechanical properties have proven advantageous for replacing traditional aggregates.

Other materials evaluated as fillers for flexible pavements include ceramic waste and marble dust. Studies have demonstrated that ceramic and marble waste meet the minimum international standards requirements for mineral fillers used in bituminous mixes.

The scanning electron microscope (SEM) test. Image Credit: Benjeddou, O & Mashaan, N et al., Sustainability

Marble Waste

Marble waste has been evaluated for use in many construction materials. Studies have been carried out into its ability to improve the mechanical properties of concrete, as a material for incorporation in Portland cement, and as additives in industrial bricks. Studies have also investigated the use of this waste material for soil stabilization.

However, few studies have concentrated on its use as an aggregate for road construction. One study has investigated its inclusion as an aggregate in base layers, with test results demonstrating that aggregates of marble waste satisfy the minimum standard requirements for base layer materials.

Other studies have evaluated marble waste powder as a filler for concrete asphalt and using marble waste to replace sand in high-quality concrete pavement. Research has indicated that incorporating this material into asphalt imparts superior flexibility performance. Marble dust can replace 20-30% of soil in sub-grade preparations, improving the strength and stability of the layer.

Overall, observations have demonstrated that marble waste used as an aggregate possesses acceptable properties for road and flexible pavement construction without affecting the quality of materials used for this purpose.

The Study

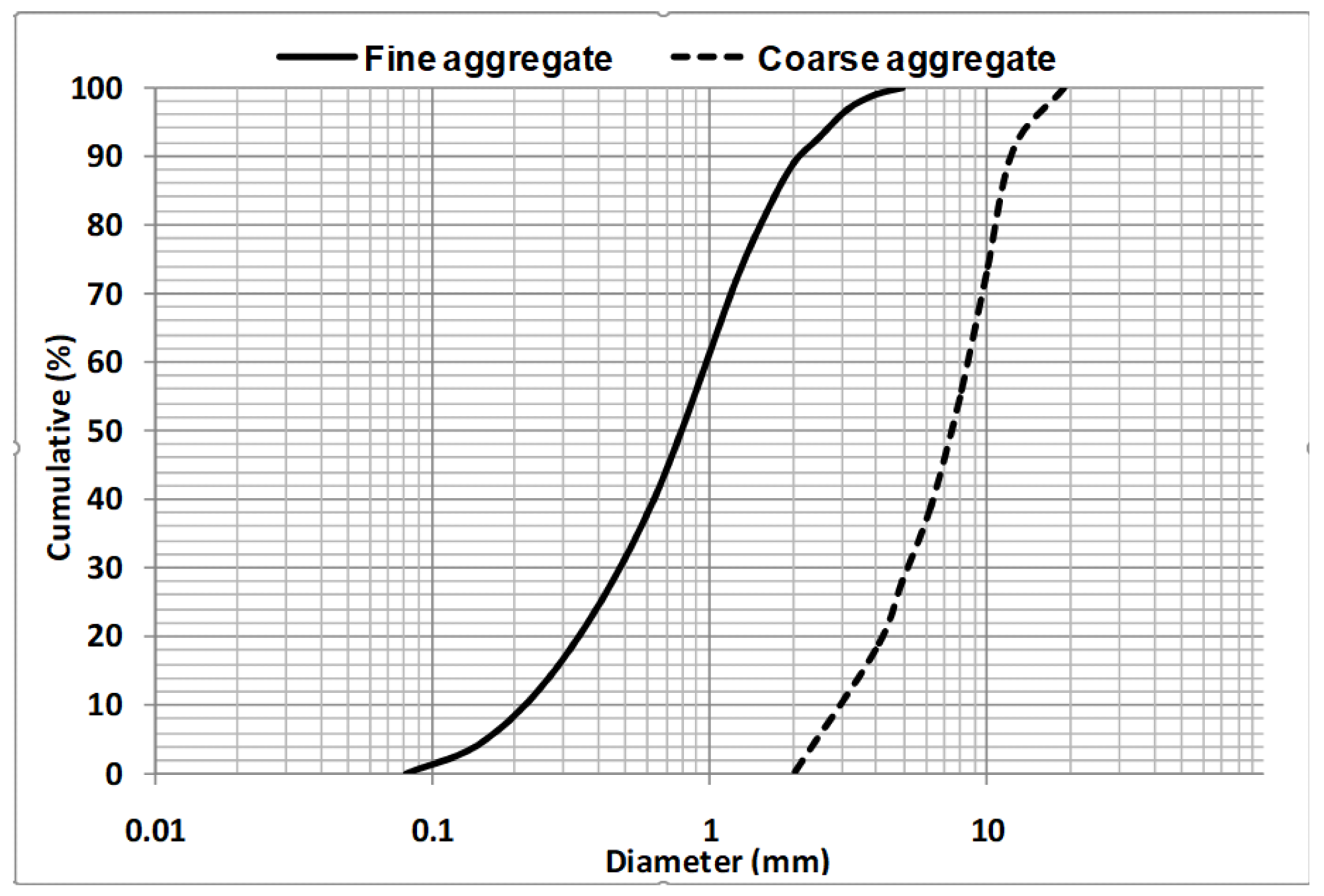

The study published in the journal Sustainability has investigated using crushed marble waste as aggregates to replace conventional aggregates in road construction. Waste material was collected by the researchers from a marble factory. A three-step method was used to obtain both fine and coarse samples. This method used a hammer, crushing machine, and a final sieving step.

A calcimeter was used to investigate the content of calcium carbonate in the samples. XRD and Scanning Electron Microscopy were used to analyze the microstructure of the samples to provide information on the mineralogical composition and the morphology of the prepared marble waste samples. The waste material’s hydraulic properties were studied.

Additionally, the authors analyzed particle size, measured the absolute densities and bulk densities of the fine and coarse aggregate samples, and obtained the sample’s water absorption coefficient. Micro-Deval, and Los Angeles tests were carried out in the research to measure aggregate abrasion and toughness. Furthermore, the flakiness and elongation indexes of the samples were determined in the research.

Particle size distribution curves of marble aggregates. Image Credit: Benjeddou, O & Mashaan, N et al., Sustainability

Analysis results demonstrated the advantageous properties of marble waste. Observations included acceptable resistance to abrasion and fragmentation, there is no clay fraction, the water absorption coefficient is lower than the acceptable value for conventional aggregates, a lack of pozzolanic activity in the presence of water, and maximum flakiness and elongation indexes well below the acceptable standards.

The authors also proposed a four-step system for crushing and storing marble waste aggregates. Based on their analysis, the authors have concluded that marble waste possesses acceptable physical, chemical, and mechanical properties for use as road aggregates. They have stated that future works will include preparing samples of concrete asphalt with marble waste aggregates for experimental observation.

Further Reading

Benjeddou, O & Mashaan, N (2022) Experimental Study of the Usability of Recycling Marble Waste as Aggregate for Road Construction [online] Sustainability 14(6) 3195 | mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/6/3195

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.