By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 15 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 15 2022In an article recently published in the open-access journal Nanomaterials, researchers discussed the potential of few-layered graphene additives in effectively tuning the performance of conductive silicon compounds.

Study: Effective Tuning of the Performance of Conductive Silicon Compound by Few-Layered Graphene Additives. Image Credit: 3d_illustrator/Shutterstock.com

Background

The strain on the high-voltage transmission and substation equipment is continually increasing as the coverage of new ultra-high voltage transmission expands. Electrical joint compounds (EJCs) have been offered as a possible alternative to improve electrical contact reliability in recent years. High-quality EJC should have strong electrical conductivity and acceptable friction qualities, in addition to high-temperature stability and moderate hardness, and the latter two properties are more difficult to develop.

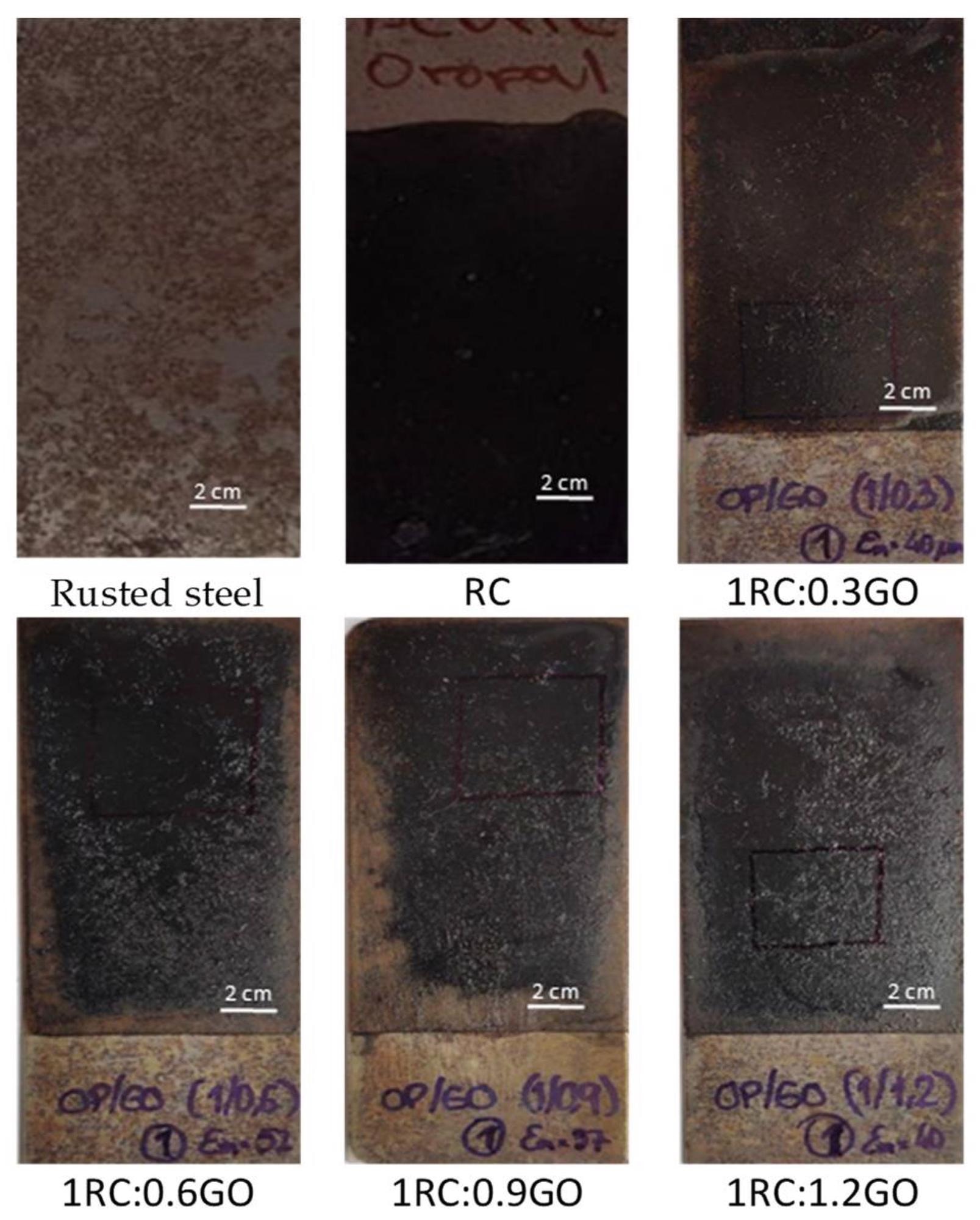

Pictures of rusted steel samples that were coated using the different RC:GO ratios, with 80 mm × 30 mm × 1 mm dimensions. Image Credit: Wu, Z et al., Nanomaterials

Some researchers have enhanced the contact qualities of conductive fillers by using nanometal elements to increase the specific surface area of the fillers. Carbon-based materials offer a higher electrical conductivity, a bigger specific surface area, and a lower cost than nano-metal particles, making them a viable option for improving EJC performance.

Mechanically exfoliated few-layered graphene (MEG) provides a low defect density, low cost, and eco-friendly preparation procedure to increase the key performance of silicon EJCs because of its chemical stability and strong thermal and electric conductivity.

About the Study

In the present study, the authors investigated the impact of MEG content on the physicochemical parameters of EJC to solve the problem of low contact reliability of electrical joints in high-power transmission and distribution equipment. Various amounts of few-layer MEG prepared using the traditional mechanically exfoliated method were added to conductive silicon compounds, and various physicochemical properties were systematically assessed and compared to those with copper additive.

The conductive fillers were copper, graphite, and graphene, and the electrical joint compound was made with phenylmethyl silicone oil as the foundation oil. The electrical joint compound's cone penetration, dropping point, volume resistivity, and friction properties were studied.

The impact of adding MEG on the material volume resistivity, mechanical and thermal stability of EJC was illustrated. To modify the physicochemical features of EJCs, MEG was used as an addition. To systematically characterize the performance of the resulting EJCs, a variety of measurements was utilized, including penetration, drip point, volume resistivity, and frictional properties.

The effect of adding MEG on the frictional properties, drip point, and penetration was also determined. The mechanically exfoliated graphene was made by utilizing expanded graphite as the raw material as well as a high-pressure homogenization and a high-vacuum shear grinding process. Atomic force microscopy, field emission scanning electron microscopy, infrared spectroscopy, and Raman spectroscopy were used to characterize the produced samples.

![X-ray patterns obtained for dried rust powder and rust + RC mixture after being in contact for 15 days. The identification of the main crystalline compounds is also included together with the diffraction planes in each identified species based on refs. [31,32,33].](https://www.azom.com/images/news/ImageForNews_58530_16473418124699404.jpg)

X-ray patterns obtained for dried rust powder and rust + RC mixture after being in contact for 15 days. The identification of the main crystalline compounds is also included together with the diffraction planes in each identified species. Image Credit: Wu, Z et al., Nanomaterials

Observations

MEG was spread in small flakes with a single lateral size of 0.5–5 µm. The MEG skeletal structure was characterized by a strong C=C bond vibration characteristic peak near 1580 cm-1. The action of water molecules in air and water used in the fabrication of MEG was found responsible for the –OH hydroxyl stretching vibration peak around 3437 cm-1 and the –OH hydroxyl bending vibration peak near 1632 cm-1. Graphite power grease and copper powder power grease reduced cone penetration by 18.7 and 14.9, respectively.

The obtained mechanically exfoliated graphene had an average number of layers of 5–6, with fewer in-plane flaws and smooth surfaces. With a value of 26.4, the cone penetration corresponding to the MEG power grease was lowered the most.

When the MEG concentration was between 2 and 4 wt%, penetration was within a tolerable range. When compared to pure copper fraction and graphite-added compound grease at the same filler ratio, MEG-added compound grease had the highest dropping point, with a maximum value of 330 degrees at 3 wt% MEG filler.

The cone penetration corresponding to the power complex grease dropped as the filler ratio increased, and the decrease in cone penetration was more noticeable when the graphene ratio changed. The electrical joint compound's dropping point increased initially and subsequently declined as the filler concentration was increased, with the electrical joint compound comprised of mechanically exfoliated graphene having the highest dropping point at a 3 wt% graphene ratio.

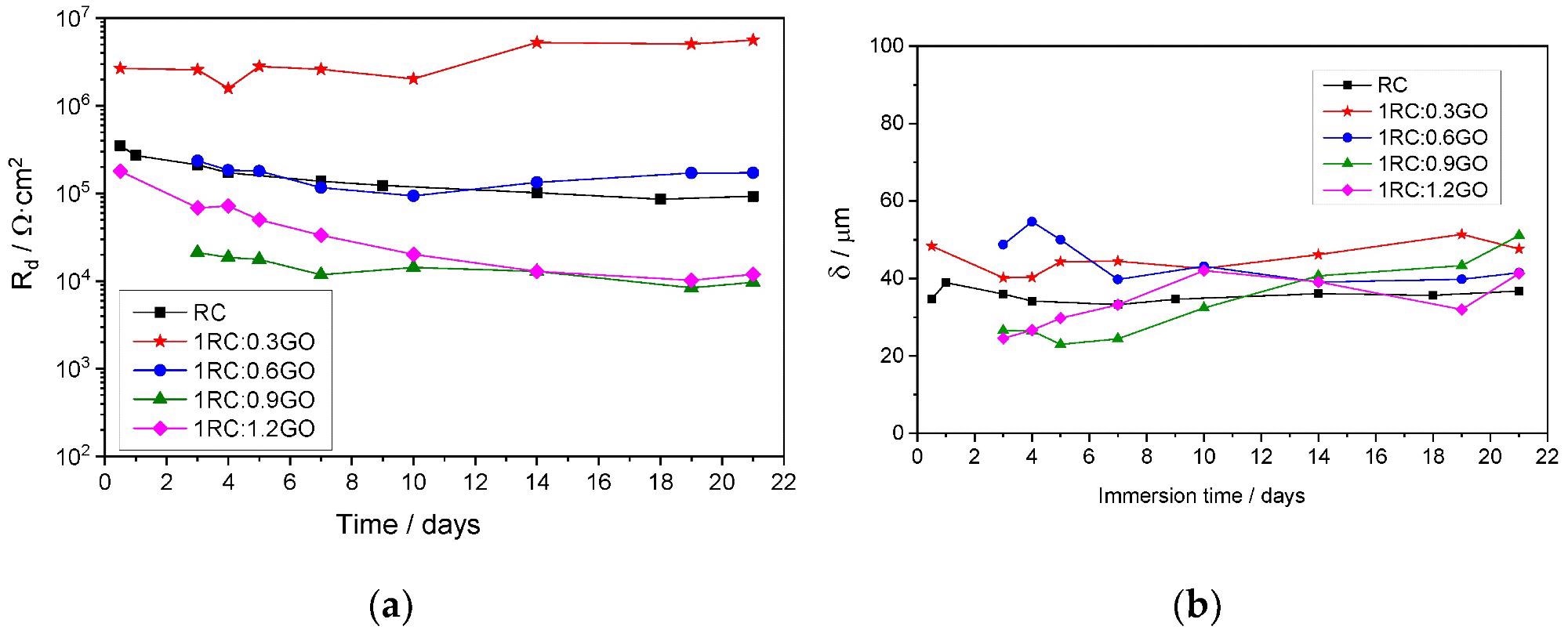

Evolution with the immersion time of (a) Rd and (b) the diffusion length δ. Image Credit: Wu, Z et al., Nanomaterials

Conclusions

In conclusion, this study provides the road for improved nanomaterials to increase the main performance of electric conductive silicon compounds.

In comparison to the other controls, the volume resistivity corresponding to the graphene power loading grease fell dramatically. Furthermore, the graphene filler significantly improved the electrical joint compound's frictional qualities, with the minimum average wear spot size and friction coefficient at a 4 wt% graphene concentration.

It was discovered that graphene prepared by mechanical peeling improves drop point, electrical joint compound penetration, friction properties, and volume resistivity, all of which are beneficial to improving electrical joint contact performance and ensuring the efficient and stable transmission of electric power.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Wu, Z., Yang, H., Tian, F., et al. Effective Tuning of the Performance of Conductive Silicon Compound by Few-Layered Graphene Additives. Nanomaterials 12(6), 907 (2022). https://www.mdpi.com/2079-6412/12/3/345