In an article recently published in the open-access journal Nanomaterials, the authors reviewed the fabrication and applications of various graphene and polydimethylsiloxane (PDMS) composite-based compact wearable devices to detect the physiological state of the human body by sensing electrochemical and strain signals.

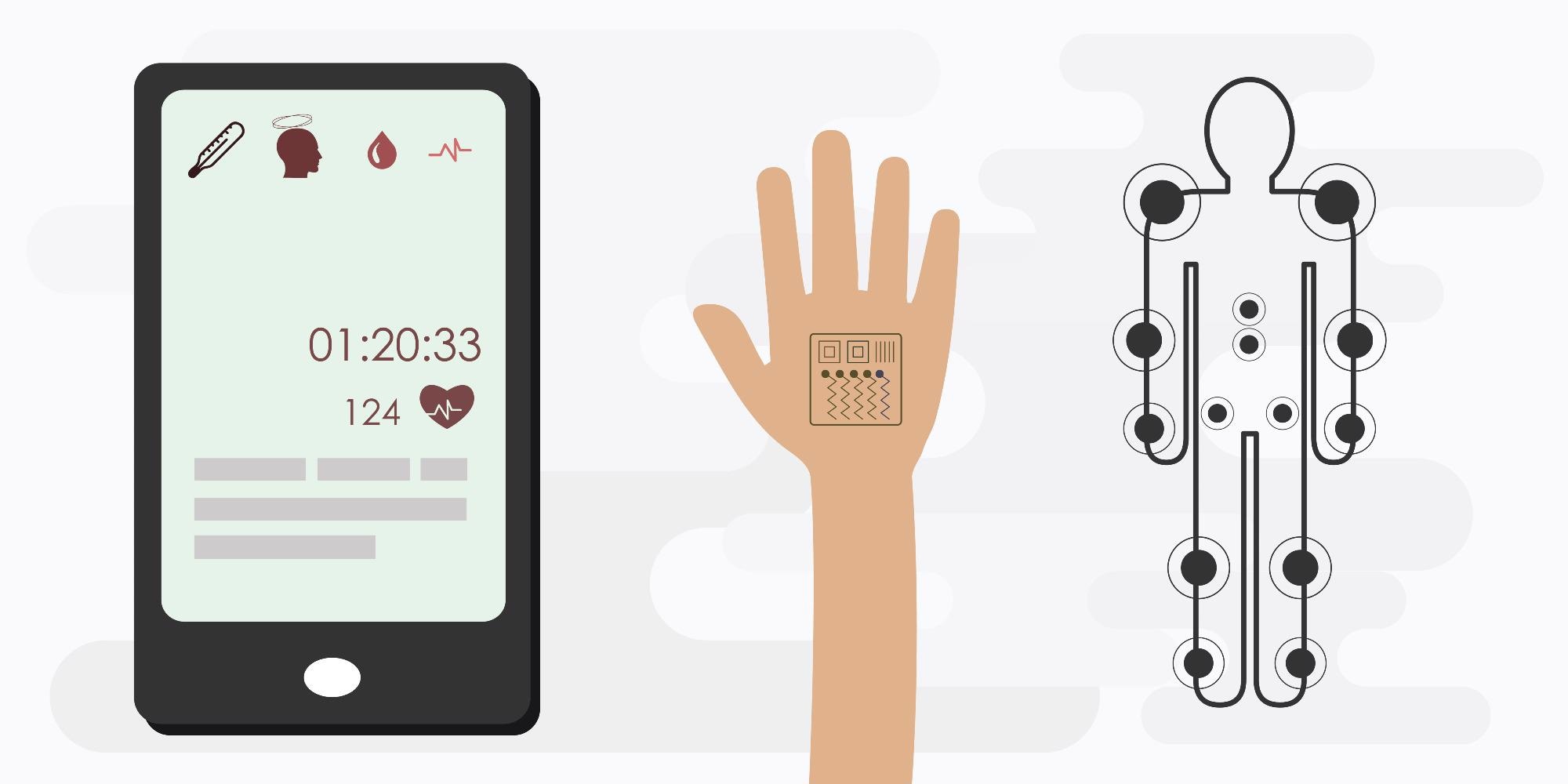

Study: Integration of Different Graphene Nanostructures with PDMS to Form Wearable Sensors. Image Credit: magic pictures/Shutterstock.com

Graphene and Polymer-Based Composites

In recent years, graphene has become the most researched material for nanotech electronic devices owing to its lowest thickness, transparency, high thermal and electrical conductivity, high mechanical strength, high aspect ratio, lightweight, and excellent control on diverse functionalization.

Moreover, it has effectively replaced earlier large integrated circuits (ICs)-based sensors, which were mostly semiconductors with silicon substrate or matrix, and conductive metallic nanoparticles deposited on it to form a continuous conducting path. However, the zero bandgap tunability of pristine graphene makes it different from semiconductors. Several methods have been shown to open up the bandgap of multilayer graphene and its composites.

Flexibility is another desired characteristic of wearable electronic devices, which can be imparted through the incorporation of polymers. Polymers such as PDMS, polyethylene terephthalate (PET), polyethylene naphthalate (PEN), and polyimide (PI) are extensively used in products that require high flexibility and mechanical properties.

Additionally, there are conductive polymers such as polyaniline (PANI), polyacetylene (PA), polypyrrole (PPy), and poly(3,4-ethylene dioxythiophene) polystyrene sulfonate (PEDOT:PSS) that require zero or very little amounts of metallic nanoparticles to form a conductive path.

Among the above-mentioned polymers, PDMS is a suitable material to form composites with graphene due to their similar properties. Both are chemically inert, optically transparent, hydrophobic, and mostly biocompatible. Additionally, PDMS is known to form strong interfacial bonding with nanofillers. These composites can add new dimensions to currently available health bands, glucose sensing strips, and smartwatches for monitoring the physiological state of the human body in terms of responsiveness and accuracy.

Types of Graphene-PDMS-Based Sensors

Graphene nanopowder-based:

Graphene in nanopowder form maintains its excellent ion carrying capability. Additionally, powdered graphene can adjust with the high flexibility of its substrate without breaking its conductive network. Laser-induced multifunctional graphene powder can be deposited on a flexible PDMS/PI substrate to make blood glucose sensing electrochemical sensors.

Similarly, super-elastic rippled PDMS substrates with graphene nanopowder are used for flexible strain sensors. The stretching and squeezing of the rippled PDMS substrate under a stain affect the conductivity of the graphene powder network. Squeezing increases the electrical resistance, while stretching decreases the electrical resistance.

Reduced graphene oxide (rGO)-based:

rGO is less expensive than pristine graphene, but very minor differences in similar properties. The advantage in using rGO is its high surface area, which is crucial in absorption-based sensing applications. The higher the surface area, the higher the absorption quantity of the targeted chemical or gas. This results in higher accuracy, linearity, and cyclic stability of the measured value.

More from AZoM: A to Z of Lithium-Ion Battery Recycling

Moreover, it can induct more secondary sensing materials that enhance its multi-functionalization capability. rGO-coated silica (SiO2) nanospheres, glucose oxide, and Nafion solution deposited on a carbon nanotube (CNT) and PDMS composite substrate are used to detect glucose in sweat. Chemiresistive gas sensors are made from rGO and zinc oxide (ZnO) nanorods.

Graphene nanoplatelets (GNPs)-based:

GNPs have a size less than a micron with an average density between 0.2 and 0.4 g/cm3. The larger size of GNPs compared to graphene nanopowder results in high robustness and repeatability. GNP/polycaprolactone (PCL) mixture with PDMS masking is used for the chemiresistive detection of ethanol vapors. GNPs, platinum nanoparticles (Pt NPs), and silicone rubber composite is used as polymer electrolyte membrane fuel cell catalysts.

Graphene quantum dots (GQDs)-based:

GQDs are graphene nanoparticles with a size of less than 100 nm. GQDs/PDMS-based sensors are used to quantify CA-125 antigen, which is an ovarian cancer biomarker. These sensors consist of amino-modified glass chips with a 3-aminopropyl-trimethoxysilane (APTMS) functionalized GQDs layer that uses chemiluminescence resonance energy transfer process to capture the antibody of the CA-125 antigen.

Existing Challenges

The solvents that promote homogenous dispersion of graphene often disrupt the mechanical integrity of graphene. Moreover, the homogenous dispersion of graphene in an aqueous solution is still unachievable. The hydrophobic nature of PDMS opposes the deposition of additional layers on the sensors. Thus, they cannot be coated with protective or extra-functionalized layers. Graphene nanoparticles may agglomerate inside the PDMS matrix, which requires additional material and methods to balance its zeta potential during deposition.

Conclusions

To conclude, the authors of this article reviewed composites of PDMS and graphene group materials as wearable devices to detect the physiological state of the human body by sensing electrochemical and strain signals. In these sensors, PDMS provides a flexible and durable substrate or matrix and graphene-based materials act as electrodes.

They can be used in health bands, smartwatches, strain sensors, and, glucose, gas, and enzyme sensing devices. Moreover, they are biocompatible and biodegradable. Thus, they can add a new level of accuracy and responsiveness to existing biosensors.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

He, S., Zhang, Y., Gao, J., Nag, A., Rahaman, A., Integration of Different Graphene Nanostructures with PDMS to Form Wearable Sensors. Nanomaterials 2022, 12, 950. https://www.mdpi.com/2079-4991/12/6/950.