By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 23 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 23 2022In an article recently published in the journal Cleaner Materials, researchers discussed the utility of vaporized granite waste powder as a secondary flux material for the long-term manufacturing of ceramic tiles.

Study: Valorization of granite waste powder as a secondary flux material for sustainable production of ceramic tiles. Image Credit: DUO Studio/Shutterstock.com

Background

Ceramic tiles have emerged as one of the most extensively used decorative materials and construction materials. As a result, the demand for ceramic tiles for construction has risen dramatically in recent years and is expected to continue to rise in the future. Ceramic tiles have also been the material of choice for architectural applications.

On the other hand, the rapid expansion of the ceramic industry has resulted in a massive intake of clay raw materials, resulting in overuse and, eventually, negative environmental consequences. As a result, recycling and repurposing industrial by-products into useful resources is critical in a circular economy. One of the most common industrial by-products created by the construction industry is granite waste. Regardless of its unique chemical qualities, granite debris is routinely wasted in large quantities without being used, posing a risk to the environment.

Due to the presence of important fluxing chemicals, granite powder could be considered a suitable alternative flux material. There has been a lot of use of granite waste in the production of high-performance concrete (HCP). On the contrary, there are sparse reports on the utilization of granite powder in ceramic tile manufacturing. Granite debris can be used as a feedstock for ceramic tile manufacture since it contains a significant number of fluxing agents and alumina silicates.

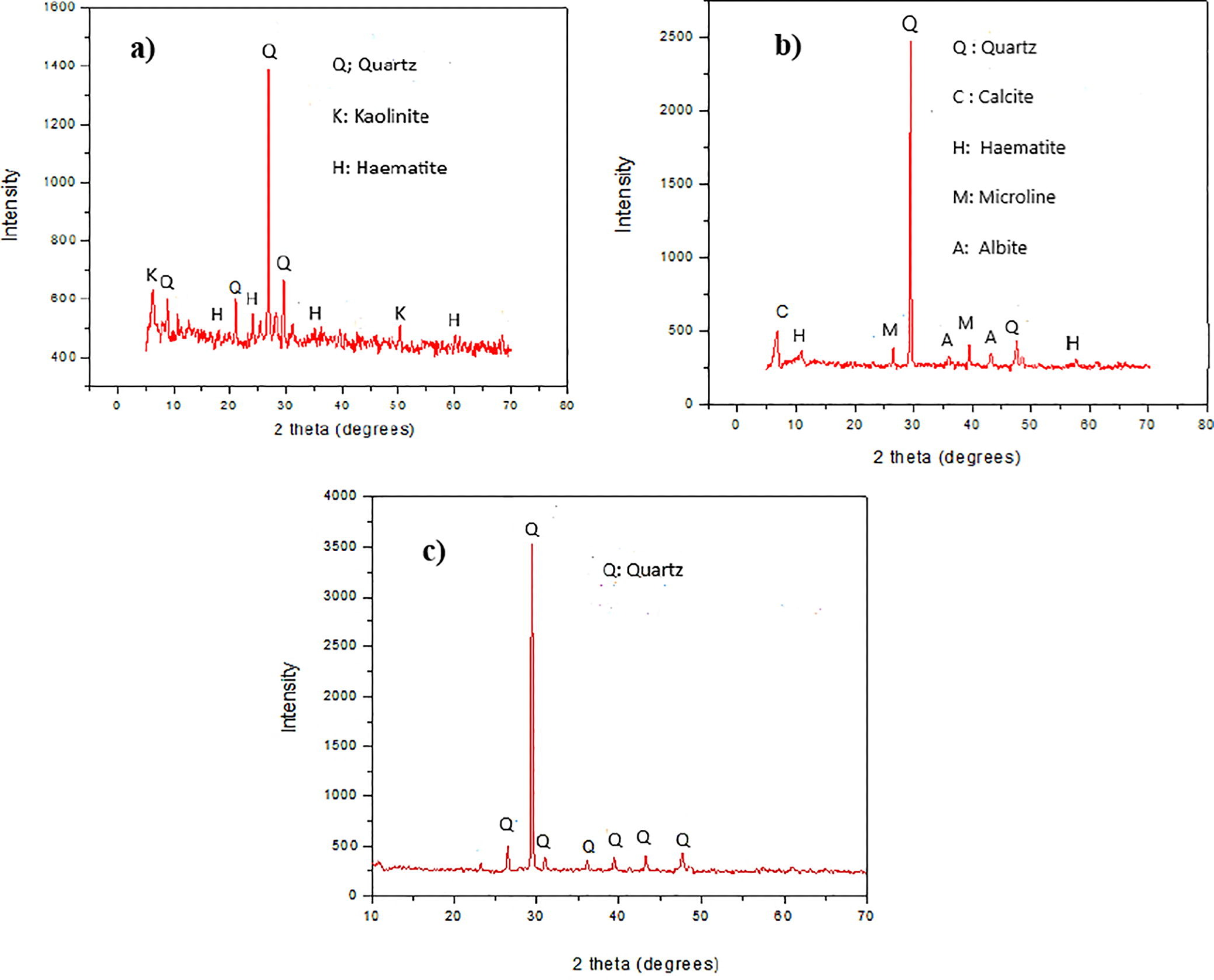

XRD patterns of a) Kaolin b) Granite powder c) Quartz. Image Credit: Ngayakamo, B et al., Cleaner Materials

About the Study

In this study, the authors proposed a viable method for the recovering and utilization of granite waste as a secondary flux in the production of ceramic tiles. To make a fine powder, the granite waste was crushed and pulverized. Different batch compositions with varying proportions of granite powder were made and burned at different sintering temperatures, i.e., 1100, 1150, and 1200 °C. Chemical compositions, mineralogical, microstructural, and physical-mechanical properties of ceramic bodies and raw materials were studied.

The team investigated the impact of altering batch compositions and sintering temperature on the mechanical strength and physical characteristics of ceramic tiles. X-ray fluorescence was used to determine the chemical makeup of the raw components (XRF). The microstructural characterization of ceramic samples and raw materials was done using scanning electron microscopy (SEM). X-ray diffraction (XRD) was used to determine the mineralogical compositions of ceramic samples and raw materials. The green bodies were made by changing the amounts of granite and kaolin while maintaining a consistent quartz concentration.

The researchers demonstrated the ideal batch compositions for achieving the best physical-mechanical properties of ceramic tiles by varying the quantity of granite powder and sintering temperature. The physical parameters, such as apparent porosity, water absorption, and bulk density, were characterized using ASTM 373–88 standard procedures. The standard method was used to conduct the compressive strength and bending tests, which followed ASTM C67 criteria. Three-point testing was used to determine bending strength.

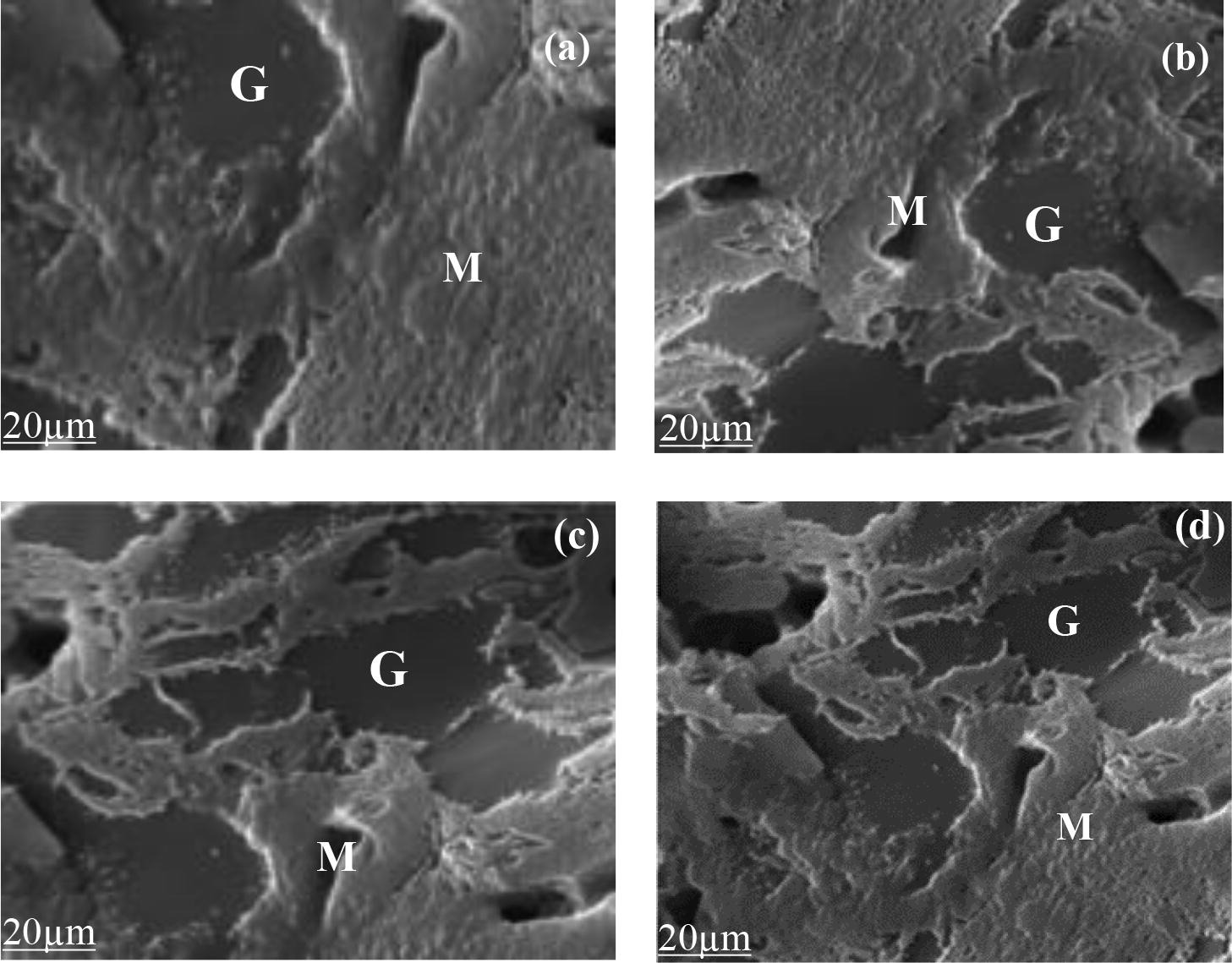

SEM micrographs of ceramic samples with a) 30 wt% of GP b) 35 wt% of GP c) 40 wt% of GP and d) 45 wt% of GP fired 1200 °C showing glass (G) and mullite (M) phase. Image Credit: Ngayakamo, B et al., Cleaner Materials

Observations

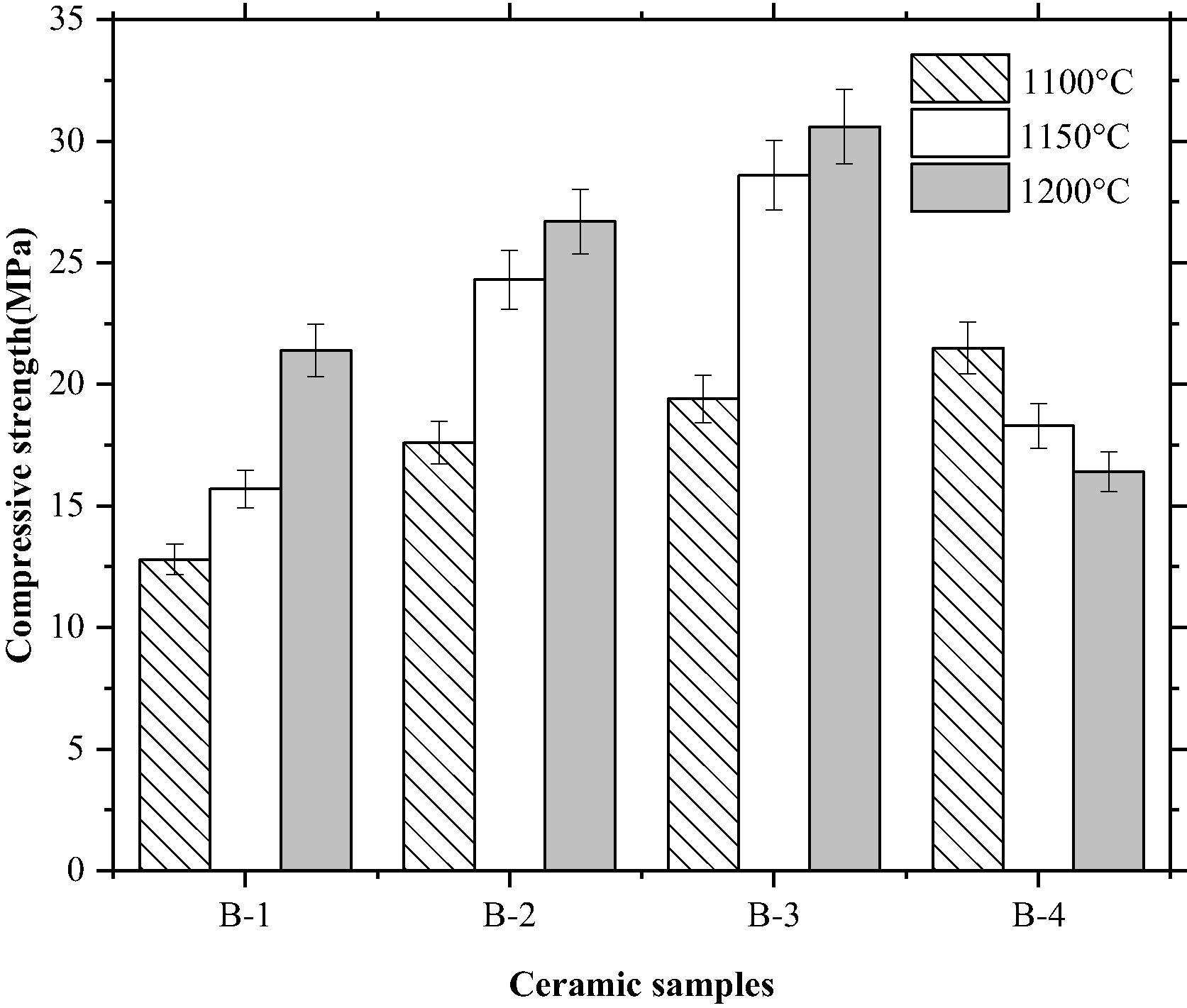

The B3 ceramic sample at 1200 °C had a maximum bending strength of 36.1 MPa and compressive strength of 30.6 MPa. At 1100, 1150, and 1200 °C, batch compositions B2 and B3, which comprised 35 and 40 wt% granite powder, had the lowest values of water absorption and apparent porosity compared to batches B1 and B4.

Fluxing agents diffused into the decomposing clay and reacted to generate mullite crystals when the firing temperature was above 1130 °C. According to the XRF study, all the raw materials had a large proportion of silica (SiO2), followed by alumina (Al2O3) in kaolin and granite powder. Fluxing agents were found in both raw materials in concentrations ranging from 0.3 to 4.74%, while granite powder had the highest concentration.

The findings revealed that altering batch compositions and sintering temperature improved the mechanical strength and physical attributes of ceramic tiles. At a firing temperature of 1200 °C, the batch composition (B3) of 50% kaolin, 40% granite powder, and 10% quartz satisfied the minimal specifications required by ISO13006 for the production of ceramic tiles.

Compressive strength of ceramic samples fired at 1100–1200 °C. Image Credit: Ngayakamo, B et al., Cleaner Materials

Conclusions

In conclusion, this study elucidated the possibility of using granite waste powder as a secondary flux material for long-term ceramic tile manufacture. The batch compositions and firing temperature had a substantial impact on the ceramic samples' physical-mechanical properties.

The authors emphasized that the use of granite waste powder as a secondary flux material in the industrial manufacture of ceramic tiles is a viable and long-term option for reducing granite waste output. They also believe that the use of granite waste as a value-added flux material will speed up the production of ceramic tiles that are both cost-effective and environmentally beneficial while reducing the massive amount of granite waste generated by the building industry.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Ngayakamo, B., Bello, A., Onwualu, A.P., Valorization of granite waste powder as a secondary flux material for sustainable production of ceramic tiles. Cleaner Materials 4 100055 (2022). https://www.sciencedirect.com/science/article/pii/S2772397622000156