By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 25 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 25 2022In a review recently published in the open-access journal Energies, researchers discussed the utility of a rice-based product in the development of a novel methodology for capturing CO2 gas from effluent gases.

Study: A New Method for Capturing CO2 from Effluent Gases Using a Rice-Based Product. Image Credit: Sarah Marchant/Shutterstock.com

Background

The United Nations' Food and Agriculture Organization (FAO) released a report in 2019 on the major drivers of global food waste, estimating that one-third of all food produced each year is wasted or lost. Food production and disposal necessitate a significant amount of land, energy, soil, and water. Greenhouse gases are produced by all parts of the food chain, and they all contribute to global warming.

CO2 emissions are known as a substantial contributor to change in climate and efforts to reduce them are proving insufficient in combating global warming. Hence, many ways of removing CO2 from the environment have been proposed. Sequestration of carbon dioxide (CO2) from power plants is one of the strategies that can be implemented to reduce CO2 emissions. However, permeance membranes and high selectivity are required for efficient CO2 separation. At least 40% of the rice available on the market is thrown away, adding to the country's CO2 emissions. Evidently, there is great potential for ecologically beneficial and cost-effective rice waste reuse.

About the Study

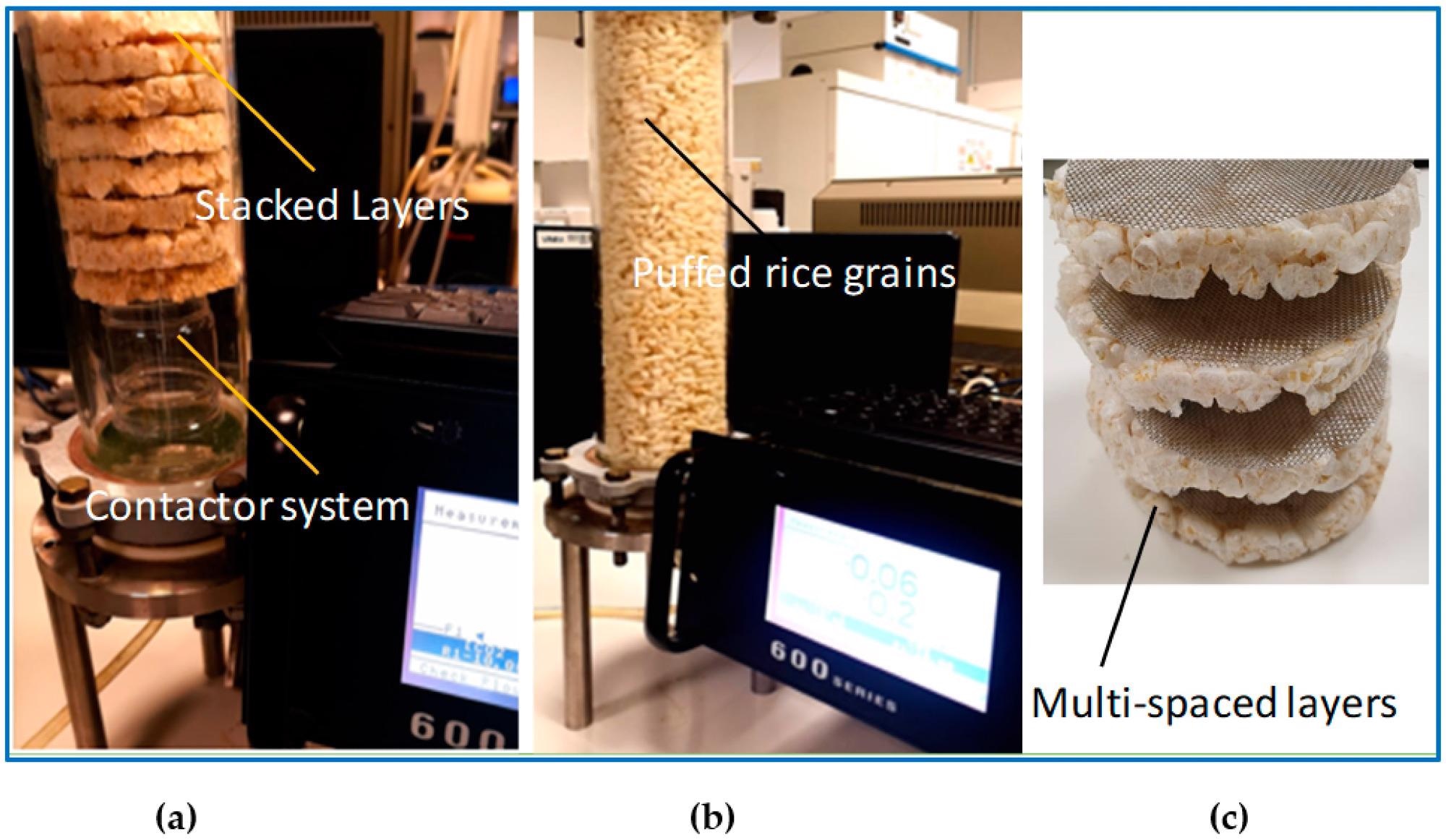

In this study, the authors provided a novel CO2 removal technology based on a specific gas contact device loaded with buffered puffed rice cakes created by heating at high pressure in a specially built sealed chamber to obtain layers with a thickness of 9-12 mm. After that, the cakes were immersed in a sodium hydroxide liquid (0.25-2.5 M) to raise the content of moisture to 5% and the pH to >11.0. Different rice structures (rice grains, stacked layers, and multi-spaced layers) were evaluated in the trials, which varied the CO2 proportion in the simulated effluent gas in the range 1-15%.

Final produced samples size, shape, and thickness. Image Credit: Mohammad, A. F et al., Energies

The team proposed a concept to lower the cost and energy consumption of CO2 removal compared to traditional methods while maintaining high removal efficiency. The proposed CO2 removal process was based on a rice-based treated product in a unique gas-contact medium design and structure. Rice products were made and puffed before being buffered with a NaOH solution. The proposed CO2 removal process was tested under various gas flow rates and NaOH molarity settings.

The authors thus developed a cost-effective, ecologically friendly, and readily available technology for CO2 capture from effluent gases by utilizing rice waste. A novel technique was suggested to aid the development of numerous industries in the food waste management sector, as well as gas emission control agencies.

Fresh puffed rice sample and sample treated with sodium hydroxide. Image Credit: Mohammad, A. F et al., Energies

Observations

With 10% CO2 and a 500 mL/min flow rate, the highest CO2 uptake value of 7.52 x 10-3 mole CO2/cm2 rice cake surface area was acquired with rice cakes having 80 mm diameter and 12 mm thick layers which occupied 20% of the device capacity. Using stacked layers of puffed rice cakes buffered with 0.5 M NaOH solution and a 500 mL/min flow rate of effluent gas, the CO2 level in a gas effluent was reduced by 38%, which corresponded to CO2 loading of 7.52 x 10-3 mole CO2/cm2 of rice cake.

The presence of voids and walls within the rice structure was also revealed by the morphological analysis as black and white colors were observed in the micrographs. When compared to the fresh puffed rice sample, the peak within the 3250-3500 cm-1 range revealed that NaOH treatment enhanced the sample absorption range.

Because of moisture loss and degradation of light organic components, sample mass decreased by 2.88% as the temperature increased from 20 to roughly 311°C. According to the thermogravimetric analysis, the sodium hydroxide treatment also resulted in a significant reduction in the rate of decomposition. Furthermore, mass losses decreased by nearly 30% at temperatures above 243.52°C.

Picture of the contactor system loaded with the operation options, (a) staked rice cake layers (b) puffed rice grains, and (c) multi-spaced layers in operation conditions, at a gas flow rate of (300 mL/min). Image Credit: Mohammad, A. F et al., Energies

Conclusions

In conclusion, this study elucidated a novel CO2 removal method based on passing effluent gas via a gas contact device loaded with puffed rice cakes. According to standard experimental observations, the proposed approach could help save money and energy while ensuring high CO2 removal efficiency. It was observed that by using another buffering waste material as a replacement, the cost of CO2 removal can be minimized.

The authors emphasized that additional research into the regeneration process is needed, and the utility of lime as a medium of regeneration with varying calcium oxide solution concentrations should be examined. They also observed that the proposed design has a high CO2 removal efficiency and believe that the benefits of the suggested technique and system, in general, are extremely encouraging for further research and statistical optimization to achieve maximum efficiency with the least operational cost.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Mohammad, A. F., Saleh, A. F. D., Khoukhi, M., et al. A New Method for Capturing CO2 from Effluent Gases Using a Rice-Based Product. Energies 15(6) 2287 (2022). https://www.mdpi.com/1996-1073/15/6/2287