By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 7 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 7 2022In a review recently published in the Chemical Engineering Journal, researchers discussed the preparation of superior graphene composite coatings using bioinspired techniques.

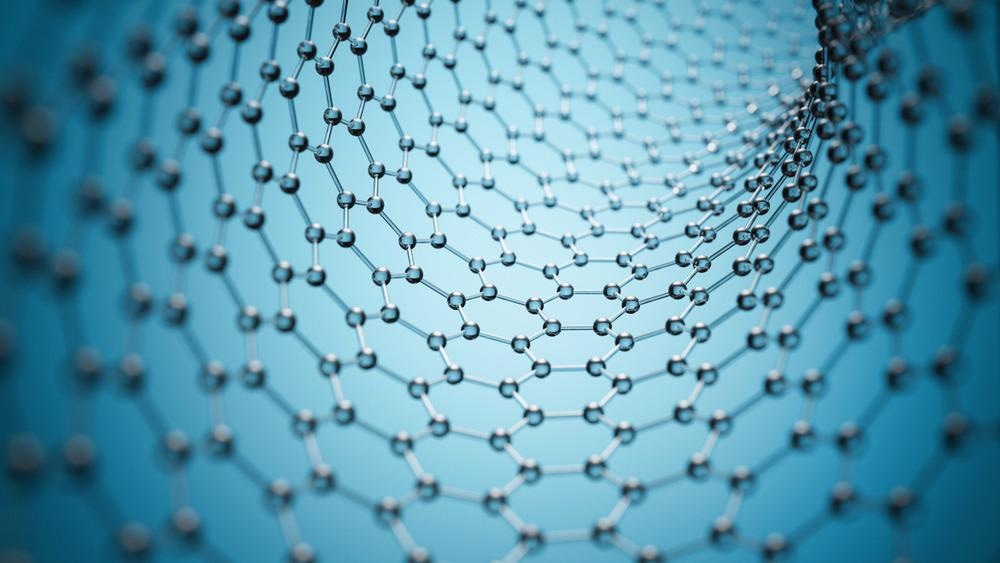

Study: Bioinspired strategies for making superior graphene composite coatings. Image Credit: koya979/Shutterstock.com

Background

Because of its unique features, graphene, the thinnest two-dimensional (2D) carbon nanomaterial, has been a research hotspot in the materials field in recent years. Graphene-based composite coatings (GCCs) with graphene nanosheets as functional fillers are very promising.

Graphene nanosheets must be embedded in high-performance GCCs before their excellent properties can be realized. Graphene nanosheet agglomeration and galvanic corrosion are two critical scientific and technological concerns that substantially hamper the actual implementation of GCCs during construction. The graphene nanosheets frequently display uncontrolled distribution and orientation interface structures rather than orderly alignment, as most earlier investigations have described.

After millions of years of development, biological systems such as nacre in bones, seashells, and woodlands have evolved to attain nearly perfect integration of structures and, consequently, optimal performance. Nacre can be used to create anticorrosion coatings that are both long-lasting and high-performing.

This bioinspired idea helps achieve effective dispersion, anisotropic characteristics, high orientation, and superior interfacial function design when compared to traditional blending methods. However, relatively few studies on nacre-inspired GCCs have been published to date, and only a few methods for creating bioinspired GCCs have been established.

About the Study

In this study, the authors discussed the link between alignment and characteristics in numerous sample orientation techniques, which covered recent research on nacre-inspired GCCs.

The researchers highlighted the bioinspired GCCs' fundamental features, such as barrier, passivation, and anticorrosion. Future perspectives and problems were also discussed in order to emphasize ways for fabricating high-performance GCCs with expected multifunction. Recent research on bioinspired GCCs was covered along with the analysis and comparison of the assembly methods, and the performance boost process was also clarified.

The fundamental features of GCCs were illustrated, such as durability, function, and galvanic corrosion behaviors. The nacre-inspired structure was used to guide future research related to the perspectives and problems for the building of high-performance GCCs.

The team addressed and compared the properties of several assembly procedures for producing high-performance graphene-based anticorrosion coatings, such as LbL, evaporation, smectic induction, flow induction, and electro-deposition.

More from AZoM: An Examination of Sustainable Adhesives

Observations

The corrosion current density of composite coatings was reduced to approximately 1.727 x 10-3 μA/cm2 from approximately 7.862 μA/cm2 for pure epoxy, while coating resistance increased to approximately 7.0 x 107 Ohm cm2 from approximately 4.0 x 106 Ohm cm2 for typical mixing coatings.

After 30 days of immersion in 3.5 wt% NaCl(aq), the resistance of the B-aG-EP coatings reached ca. 3.6 x 109 Ohm cm2, which accounted for a 1300% increase above epoxy with ca. 2.7 x 107 Ohm cm2. By embedding 6 wt% LCs GO in alginate composites, a 392% increase in Young's modulus and a 59% increase in stress were achieved.

It was also determined that since the discovery of graphene, both pure graphene sheets and GCCs have been fascinating research areas. GCCs had not yet developed mature products or reached industrialization, which could be due to the fact that some key scientific and technological issues such as random orientation, agglomeration, and galvanic corrosion of graphene had not been resolved yet.

Natural nacre could provide a fresh design idea for producing high-performance GCCs with appropriate functional properties. The advantages of this nacre-inspired strategy for preparing GCCs over traditional mixing methods included well-ordered orientation and distribution of graphene nanosheets, exceptional corrosion protection performance, elimination of graphene corrosion promotion, and desired functional properties.

Assembling the graphene nanosheets into functional and high-performance GCCs was critical for realizing graphene's wide range of applications in metal protection sectors, such as marine and space.

Conclusions

In conclusion, this study highlighted recent advances in bioinspired GCCs built using a nacre-inspired approach. The synergistic enhancing effects of the various interfacial architectures were investigated. LbL, evaporation, smectic assembly, flow induction, and electro-deposition were five common assemble techniques that were devised and demonstrated to manufacture high-performance and functional GCCs.

The authors observed that the nacre-inspired design eliminated GCC aggregation, galvanic corrosion, and random orientation, while also increasing graphene use efficiency and improving anticorrosion performance and functional characteristics.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Ding, J., Zhao, H., Yu, H., Bioinspired strategies for making superior graphene composite coatings. Chemical Engineering Journal 435(1) 134808 (2022). https://www.sciencedirect.com/science/article/abs/pii/S1385894722003151