In a recent article published in the journal Materials, the authors constructed cement composites with low percolation thresholds to obtain low-cost graphite with good mechanical properties.

Study: Smart Graphite–Cement Composites with Low Percolation Threshold. Image Credit: Bozena Fulawka/Shutterstock.com

They demonstrated the effect of exfoliated graphite on the cement composite’s mechanical and electrical properties. For testing the feasibility of the composite’s practical application, investigations were conducted on the percolation threshold, mechanical properties, piezoresistive properties, and temperature-resistivity properties.

Background

Traditional cement composites’ applications as smart materials are associated with drawbacks such as small electrical conductivity and the influence of external factors on their electrical properties. Incorporating electrically conductive materials into the cement composites can overcome these shortcomings. Such incorporation enhances the resistivity of the composites under mechanical stress and allows their applications as stress monitoring sensors, temperature sensors, heating elements, and electromagnetic radiation shields.

However, according to previous literature, the incorporation of electrically conductive materials into the cement composites may have negative effects on the mechanical properties or surface morphology of composites, thus challenging researchers to scout for more efficient methods to overcome their drawbacks. Moreover, this incorporation process is time-consuming and expensive.

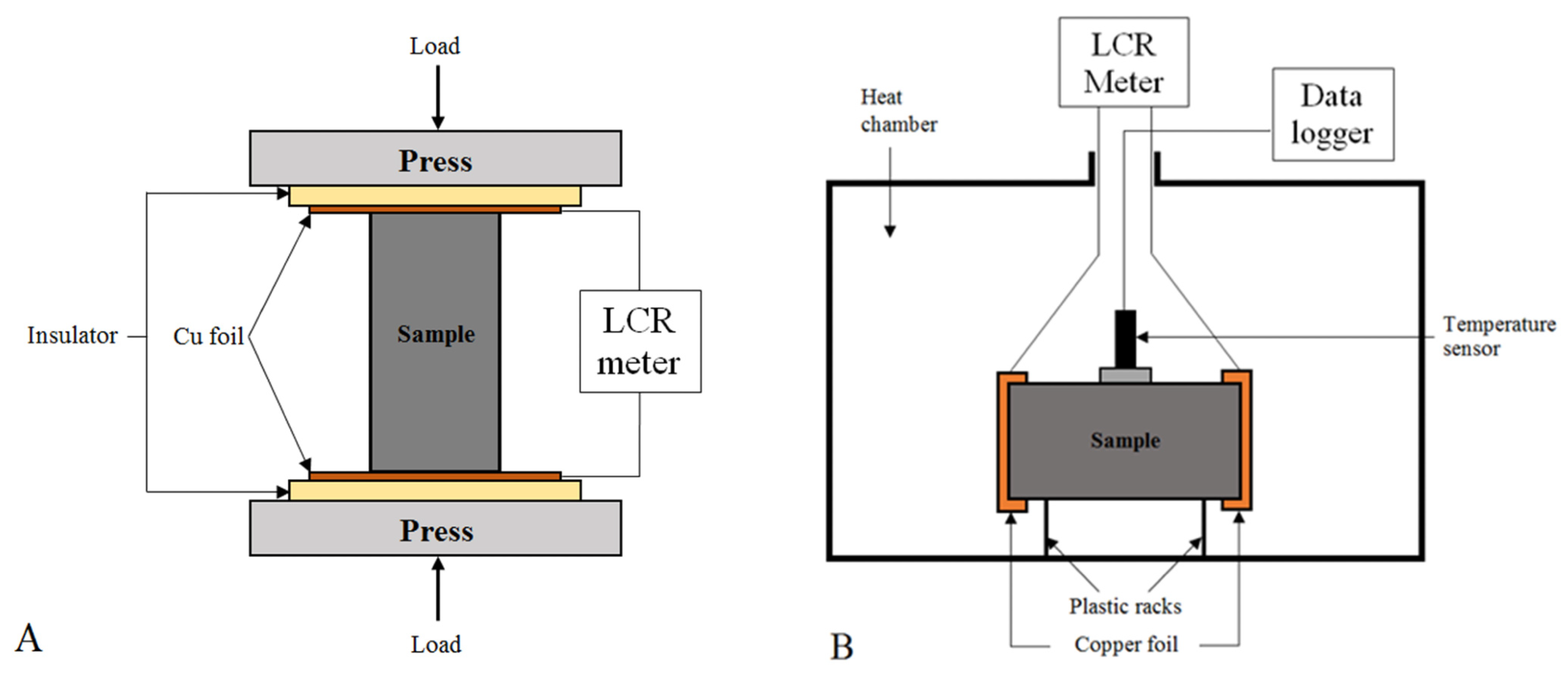

Experimental setup for (A) piezoresistive and (B) resistivity–temperature properties study. Image Credit: Frąc M et al., Materials

About the Study

In the present study, the authors constructed cement composites with low percolation thresholds to obtain cost-effective graphite with good mechanical properties. They exfoliated the expanded graphite by adding surfactants and employing ultra-sonication to the mixture. The resultant product is used as a conductive additive in cement composites. Here, the addition of surfactants reduced the surface tension, and the reaction mixture was directly added to the cement matrix, thus eliminating any additional processes and reducing the overall cost.

Further, they studied the percolation thresholds, flexural strengths, and compressive strengths to depict the electrical and mechanical properties of cement composites. To test the practical applications of the constructed composites, their temperature-resistivity and thermoelectric and piezoresistive properties were studied. Furthermore, the graphite particle size and the extent of their dispersion in the cement matrix were also investigated by the authors.

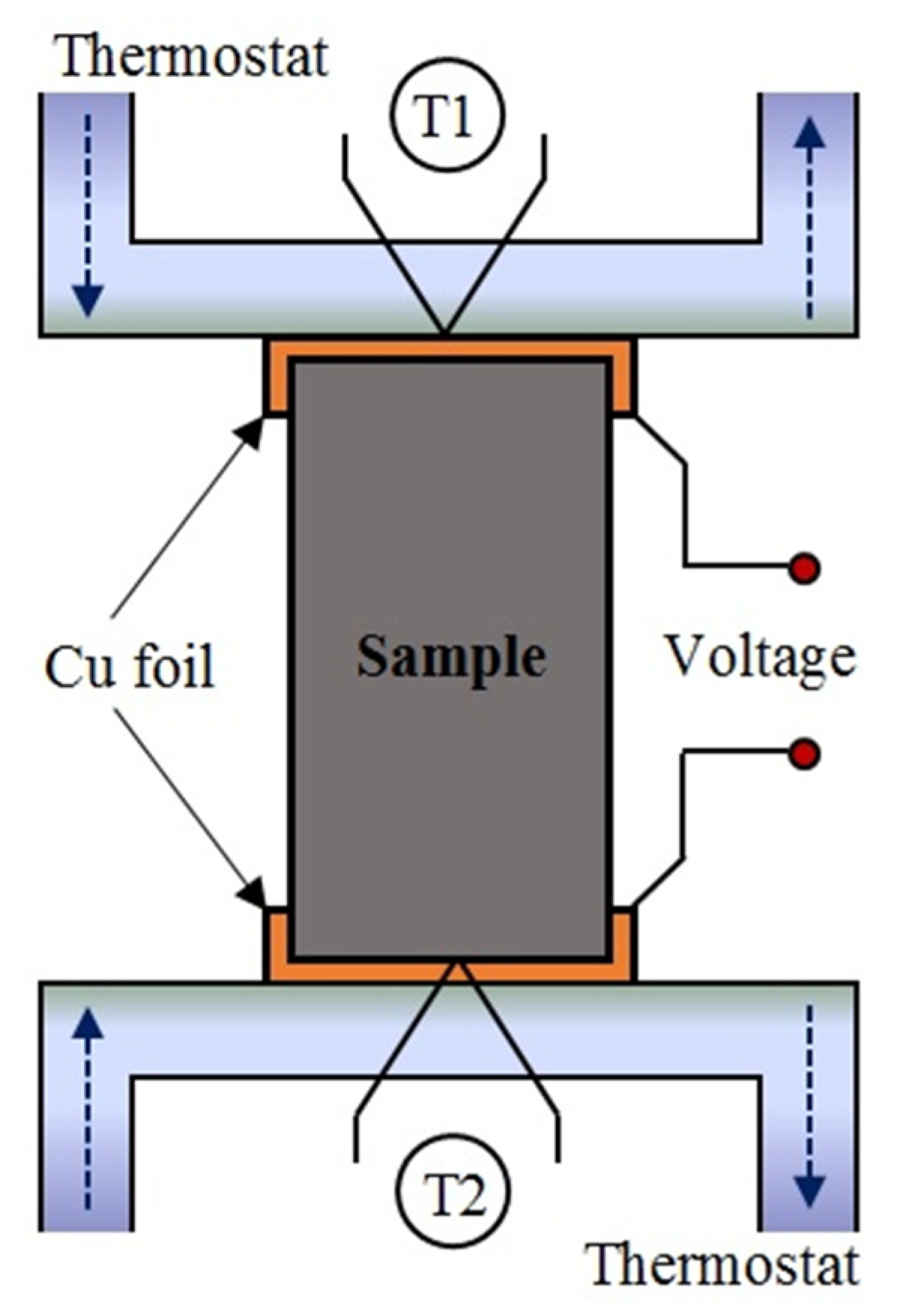

Experimental setup for the determination of thermoelectric properties. Image Credit: Frąc M et al., Materials

Observations

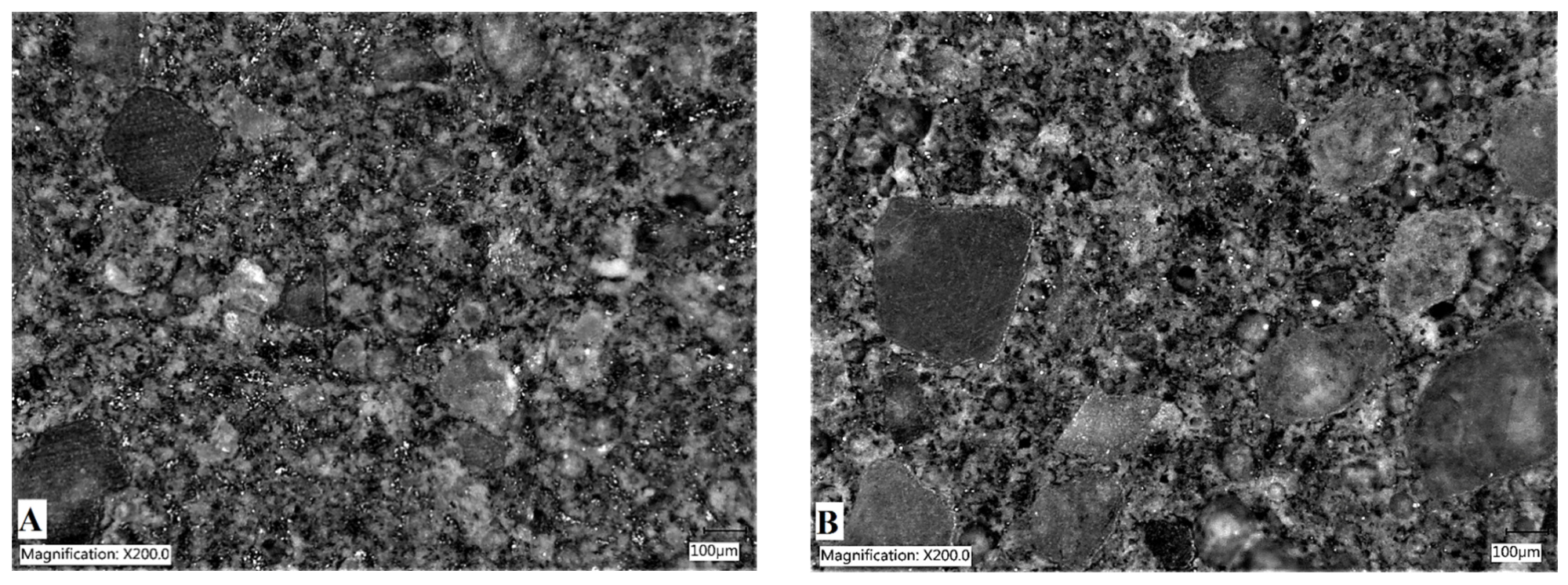

The particle size of the obtained graphite was determined from scanning electron microscope (SEM) images. The size and modal value of these particles were around 40 µm and 15 µm, respectively. The obtained graphite particles were in the form of sheets with a high aspect ratio, thus facilitating their conductive network when applied to the cement matrix.

The microscopic images of the obtained graphite particles reveal their uniform distribution in the cement matrix without any visible agglomerates. The even distribution of graphite particles is attributed to the addition of surfactants during the sonication process, thus demonstrating their practical applicability in smart composites. It is important to note that, although the graphite composites were evenly distributed in the cement matrix, the graphite network was visible only in composites with a graphite percentage greater than 2% by weight.

Flexural and compressive strength measurements imply a decrease in mechanical strength with increasing graphite content. According to the authors, this decreasing trend is due to the air introduced during the addition of surfactants, which increased the porosity and weakened the exfoliated graphite and matrix’s bond strength. Nevertheless, the values of mechanical strength do not impact its practical application.

The effect of graphite content on the resistivity of composites was determined in the presence and absence of surfactants. The results revealed that the resistivity of composites showed a better decrease in the presence of a surfactant. Further, the resistivity of the composites significantly dropped with the increase in graphite content. Thus, it was inferred that the addition of surfactants aided in the formation of the graphite network due to better dispersion.

The percolation threshold was determined using impedance spectroscopy (IS), and the results show that the percolation threshold was exceeded for composites with 2% graphite by weight. Additionally, the measurement of piezoresistive properties of the cement composites showed that a measurable resistivity change with stress was observed in composites with graphite content greater than 2% by weight. These results reveal the importance of exfoliated graphite in cement composites for their application as stress sensors.

The results obtained from the analysis of temperature–resistivity properties showed that the composites with graphite content greater than 2% by weight had a linear relationship with temperature changes during heating and cooling. Additionally, the results obtained from the study of thermoelectric properties showed that composites with graphite greater than 1.43% by volume could be used in smart applications for temperature sensing.

Microscopy images of composites with graphite content: (A) 2 wt% and (B) 1 wt%; graphite particle—black color, cement matrix and sand—lighter color. Image Credit: Frąc M et al., Materials

Conclusions

The novel ultrasonication-assisted graphite exfoliation performed in this study with the addition of surfactants has proven its efficiency in obtaining graphite with a smaller particle size. Moreover, the direct addition of the reaction mixture with an excess surfactant to the cement matrix aided in the uniform distribution of graphite throughout the cement matrix, resulting in a good conductive network.

The exfoliated graphite obtained via this cost-effective strategy reveals its potential as a promising low-cost conductive additive for cement composites. The results obtained from the various analyses reveal the practical applicability of the obtained composites as stress monitors and temperature sensors.

Source:

Frąc M, Szołdra P, Pichór W. Smart Graphite–Cement Composites with Low Percolation Threshold. Materials (2022); 15, 8, 2770. https://www.mdpi.com/1996-1944/15/8/2770#cite