The deformation characteristics of metals alter dramatically at the micrometer scale: bulk materials’ smooth and continuous behavior typically becomes jerky owing to random strain bursts of varied sizes.

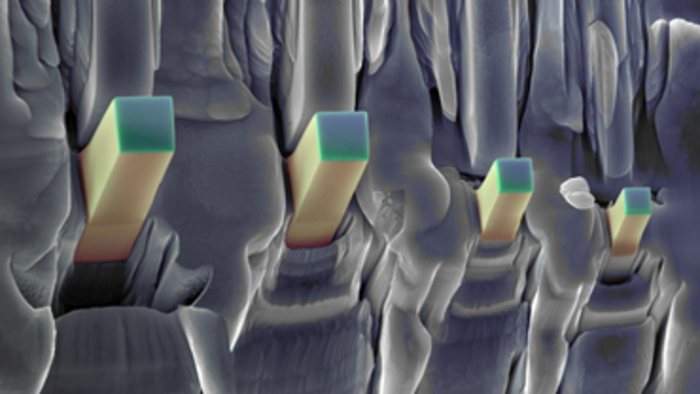

On the micrometer scale deformation properties of metals change profoundly: the smooth and continuous behavior of bulk materials often becomes jerky due to random strain bursts of various sizes. Image Credit: Péter Dusán Ispánovity and Dávid Ugi.

On the micrometer scale deformation properties of metals change profoundly: the smooth and continuous behavior of bulk materials often becomes jerky due to random strain bursts of various sizes. Image Credit: Péter Dusán Ispánovity and Dávid Ugi.

The reason for this situation is the complicated intermittent redistribution of lattice dislocations (line-like crystal defects that cause irreversible deformation of crystalline materials) caused by external loading, which is also the reason for the creation of the uneven step-like surface during deformation.

To better understand this phenomenon, researchers from Budapest’s Eötvös Loránd University, Prague’s Charles University and Saint-Étienne’s Écola des Mines devised an extremely sensitive micromechanical platform that detects weak elastic waves released by the specimen during micron-scale pillar deformation.

Compression investigations using a scanning electron microscope on certain zinc single-crystalline micropillars proved that these so-called acoustic signals do indeed arise during strain bursts, allowing us to hear the “sound of dislocations” for the first time.

As the acoustic waves are recorded at a rate of 2.5 MHz, they give exceptionally comprehensive information about dislocation dynamics. The researchers’ in-depth statistical analysis showed that strain bursts have a two-level structure: what seems to be a single plastic slip is, in fact, the product of multiple connected occurrences over a μs–ms period.

The experiment’s most surprising finding is that in this procedure, despite the basic distinctions between metal deformation mechanisms and tectonic plate deformation mechanisms, earthquakes were discovered to be perfectly comparable.

The testpieces’ acoustic signals followed basic empirical principles established in seismology for major shocks and aftershocks, including the Gutenberg-Richter and Omori laws.

These results are expected to bear high technological impact since, for the first time, we were able to observe direct connection between acoustic signals and the plastic events that emitted them.

Péter Dusán Ispánovity, Assistant Professor and Head, Micromechanics and Multiscale Modelling Research Group, Eötvös Loránd University

Dusán Ispánovity added, “Since the measurement of acoustic emission is a frequent method for monitoring and locating material failure in technological applications, by providing fundamentally new information about the underlying physics our results are expected to contribute to the further development of this technique.”

These experiments are rather complex since one has to couple the nanometer precision manipulation tool with the extremely sensitive acoustic sensor, all in the vacuum chamber of a scanning electron microscope. Such measurements, to our knowledge, at the moment can only be performed at our laboratory.

Dávid Ugi, Study Corresponding Author and PhD Student, Eötvös Loránd University

Dávid Ugi is a student in the group of Ispánovity,

The approach may be applied to other forms of deformation processes, such as twinning or fracture, and the findings, which were reported in Nature Communications, are likely to open up new possibilities in the study of micromechanical properties of materials.

Journal Reference:

Ispánovity, P. D., et al. (2022) Dislocation avalanches are like earthquakes on the micron scale. Nature Communications. doi.org/10.1038/s41467-022-29044-7.