A team of scientists writing in the journal Polymers has investigated the development of lead-free polymer composites for use as materials in radiation-shielding clothing. This will overcome the traditional challenges with protective clothing, which typically contain lead.

Study: Lead-Free Multilayered Polymer Composites for Radiation Shielding. Image Credit: Ket Sang/Shutterstock.com

Replacing Lead in Medical Clothing

Concerns about the adequate protection of both patients and medical professionals during medical procedures using radiation have led to the development of clothing that can withstand irradiation. Lead-impregnated aprons and gloves are the standard protective clothing used in medical procedures, but lead is highly toxic despite its superior shielding properties, which can cause harmful health effects.

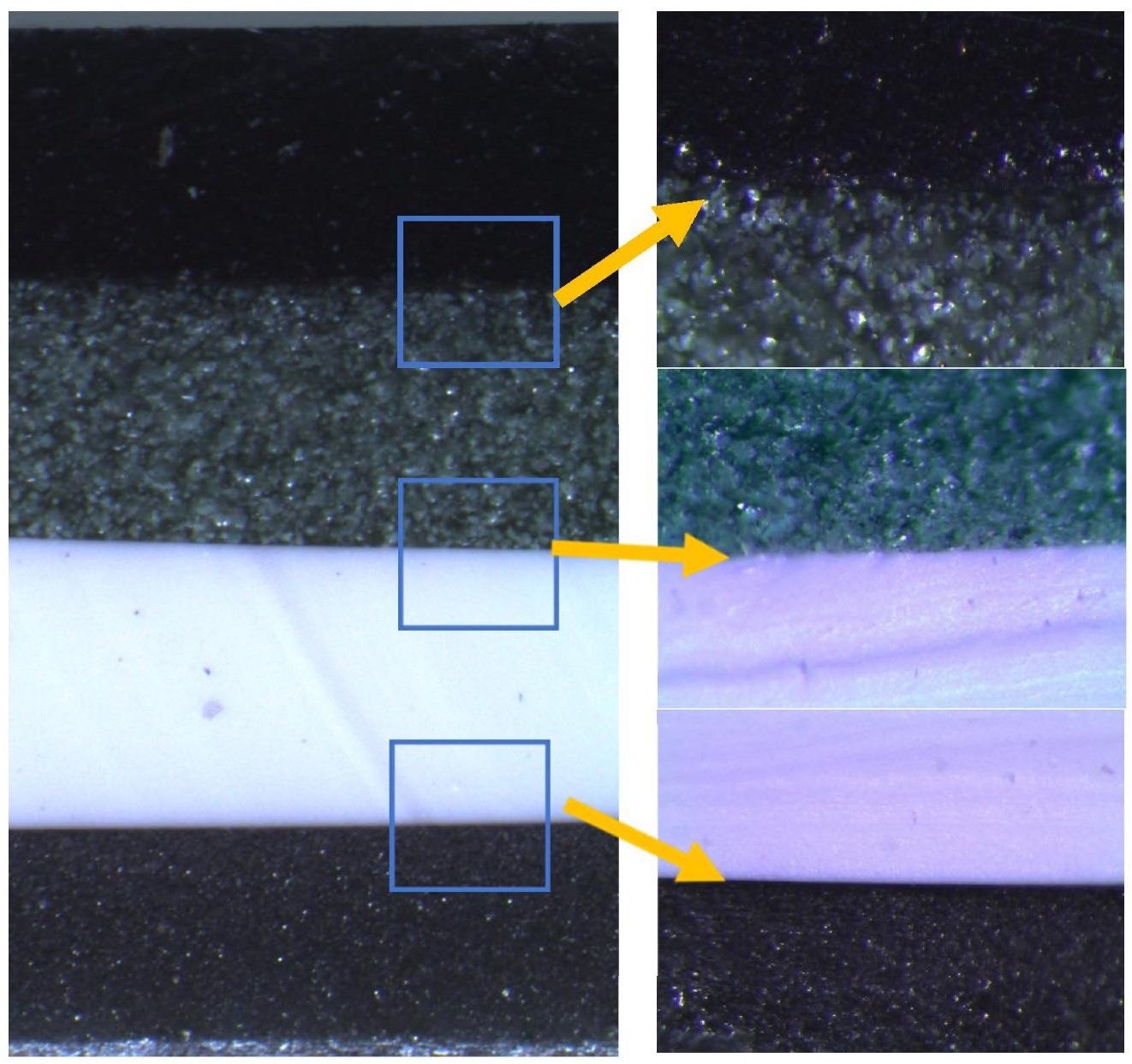

Cross-section of the multilayer composite and the interface between layers. Image Credit: Gilys, L et al., Polymers

Other challenges exist with these clothing items. Lead is not just highly toxic to humans - it can also cause environmental damage which facilitates specialist, complex, and costly recycling procedures. Additionally, lead-impregnated protective clothing is heavy, and incorrect handling and daily use can cause damage to fabric structure, reducing its radiation shielding effectiveness. There is a need for new, innovative materials which overcome these limitations.

Radiation-Shielding Polymer Composites

The development of lead-free, safe, reliable, and robust polymer composites and fabrication technologies has progressed immensely in the past few decades. Amongst polymers proposed for this purpose, those containing additives such as tungsten, bismuth, and tantalum are promising. This is due to their superior X-ray absorption and physical and mechanical characteristics.

Mechanically stable and flexible solid materials can be manufactured by selecting composite polymers. Additionally, they can be easily chemically modified using facile and controllable processes. Polymers that have been widely explored for use as matrix materials in radiation-shielding composites include ultra-high molecular weight polyethylene, epoxy, silicon rubber, and polylactic acid.

Modifications for polymer composites have been investigated by researchers, including radiation crosslinking, polymer degradation, and radiation-induced polymerization. Research has indicated that polymers such as urethane rubber and silicone rubber can resist high doses of radiation. When irradiated, changes occur in the material, such as increased hardness and decreased elongation, which has been attributed to increased cross-linking density.

Experimental samples prepared for tensile tests, following ISO 6721 standard requirements. From the left: pure silicone samples; 1 and 2—0.8 mmol/g multilayer silicone composites samples; 3 and 4—1.6 mmol/g multilayer silicone composites samples; 5 and 6—3.2 mmol/g multilayer silicone composites samples. Image Credit: Gilys, L et al., Polymers

Currently, despite promising research results, there are several limitations and challenges that occur with the adoption of new polymeric radiation shielding materials for the medical industry. For instance, not all materials can be used for radiation-shielding purposes due to the specific requirements of the medical industry.

Flexibility is hindered by the hard, solid nature of many of the materials. Furthermore, producing homogenous composites is challenging when incorporating composites materials of varied sizes and shapes. Heavier materials can settle, and solidifying composites can be a time-consuming process. Some strategies, such as producing multi-layered composites, have been proposed to overcome this issue.

The field of research is a complex one that faces many challenges. Material properties are strongly influenced by the employed manufacturing process. Nevertheless, the need for a reliable material that can address the issues with both lead-impregnated radiation shielding materials and the limitations of current polymeric radiation-shielding composites has facilitated increased research focus.

The Study

The authors have stated that, currently, there is a lack of research governing the fabrication of multi-layered lead-free polymer composites that possess superior radiation shielding and mechanical and physical properties. Therefore, the focus of the research is on the investigation of suitable polymeric composites that can replace lead in protective medical clothing.

Lead-free flexible polymer composites containing tin, tungsten, bismuth, and cerium compounds have been evaluated in the research, both separately and in multi-layered structures. The matrix polymer used in the composite material was a vinyl-terminated polydimethylsiloxane silicone rubber, which was thermally cured. The X-ray attenuation and mechanical and physical properties of these materials have been characterized in the study.

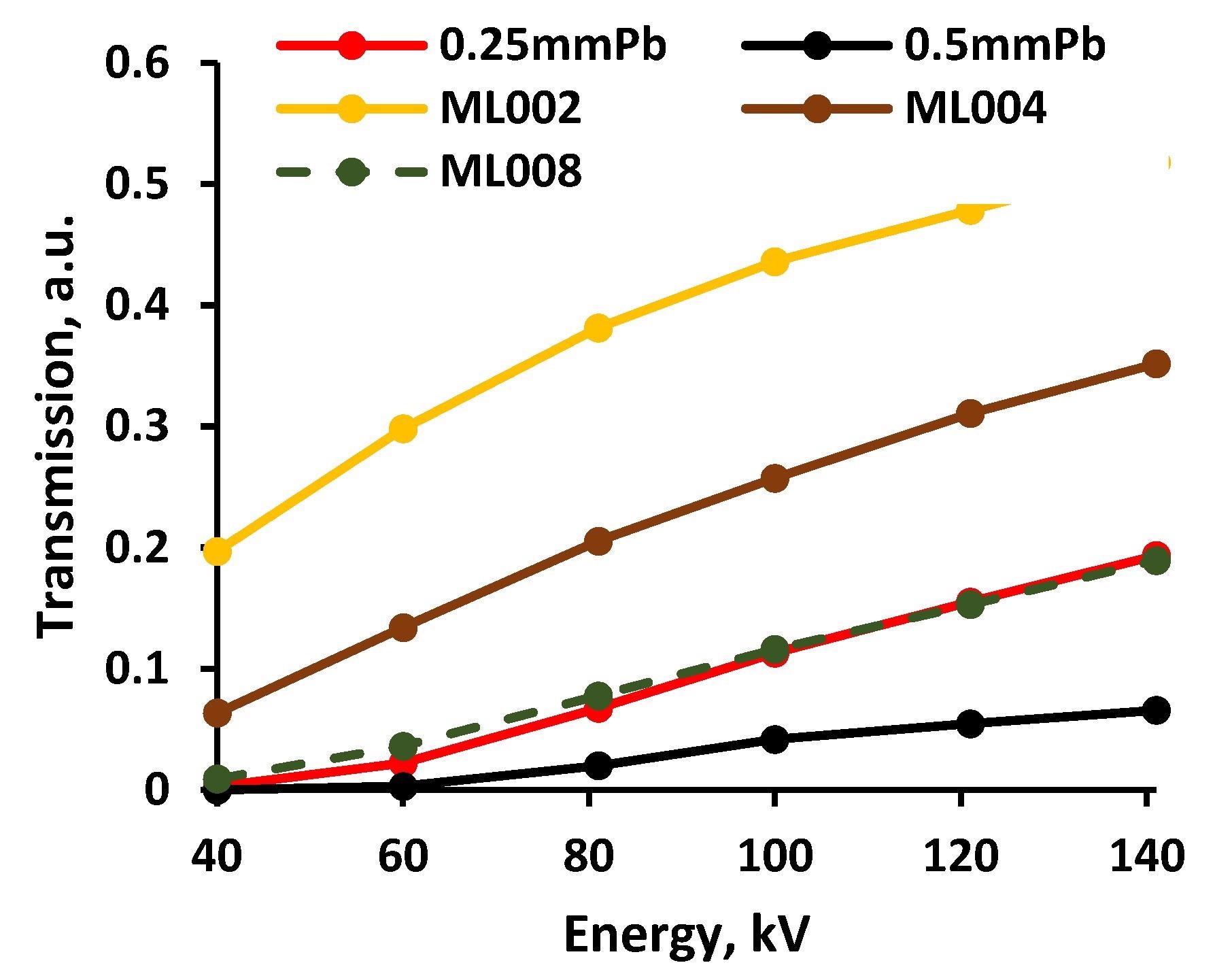

X-ray transmission coefficient variation in multilayer composites. Image Credit: Gilys, L et al., Polymers

XCOM simulations were used in the study to demonstrate the composite multi-layered material’s X-ray attenuation performance. Simulation results demonstrated superior performance to pure lead, covering the entire medical diagnostic range. The prepared composite materials displayed the same or better X-ray attenuation properties as conventional medical aprons.

An artificial sweat test was performed on the materials to simulate normal wear conditions. This test revealed that negligible amounts of metallic additives were released after the period of one month. Therefore, it was concluded that the material could perform well without any impact on its radiation shielding properties. Mechanical deterioration tests were conducted over 40,000 cycles.

The research has demonstrated the superior radiation-shielding and mechanical properties of a novel polymer composite material for replacing highly toxic lead in protective medical equipment. The authors have stated that reducing the mass of the polymer whilst retaining the same filler composition could be an elegant solution for producing flexible materials with superior radiation shielding properties, but this will come with some associated mechanical deterioration.

Further Reading

Gilys, L et al. (2022) Lead Free Multilayered Polymer Composites for Radiation Shielding Polymers 14(9) 1696 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/9/1696

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.