Reviewed by Alex SmithApr 25 2022

Special economic and environmental benefits in particular applications (for example, gas or liquid molecules) have been displayed by the adsorption-based isolation technologies.

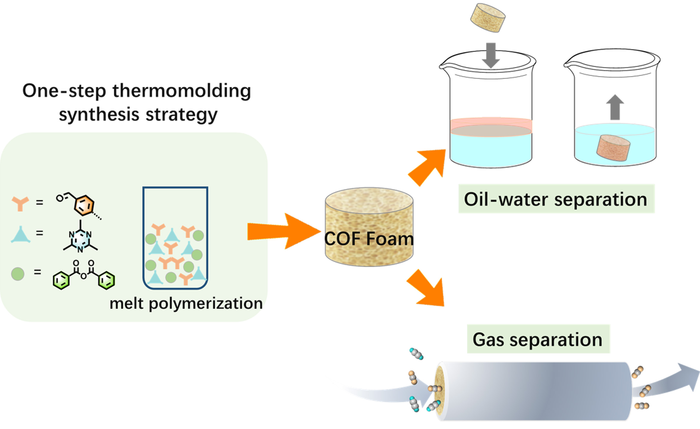

Construct covalent organic frameworks foam separators by melt polymerization. Image Credit: ©Science China Press.

Construct covalent organic frameworks foam separators by melt polymerization. Image Credit: ©Science China Press.

As far as industrial applications are concerned, perfect high-efficiency adsorbents not only need high adsorption capacity or selectivity but also require good machinability, mechanical stability and cycling. Hence, it is essential to arrange the adsorbents into high-stability monoliths (for instance, aerogels, membranes, spheres, etc.).

In recent times, the so-called COFs, as a developing class of advanced adsorbents, have illustrated several inspiring performances in several separation fields. But the majority of the advanced COF adsorbents still lack stability (mostly constructed by the reversible bond linkages), have low processability (majorly existing as microcrystalline powders), and have trouble with scalable synthesis.

Thus, it is of great importance to make new strategies to generate highly strong COF monoliths (for example, porous foams) for practical applications.

Frequently, melt polymerization techniques are utilized to make linear polymers. As both monomers and polymers are in a molten form, it is simple to directly process and shape. Having been motivated by this, Zhang’s group from Nankai University initially introduced the so-called “melt polymerization” strategy into COFs synthesis.

With the addition of benzoic anhydride as a flux, a “one-step thermoforming” technique was developed to make a range of olefin-linked COF foams.

This is due to the flux that promoted the monomers to develop a eutectic, which gradually crystallized upon heating, and eventually solidified to develop highly crystalline COF foams (density as low as 0.23 g/cm3).

Not only can this technique improve the porosity and crystallinity of the reported COFs, but it can also help generate new COFs that are hard to be achieved by adopting the conventional solvothermal techniques.

For instance, a novel olefin-linked COF (NKCOF-12) with ultra-micropores measuring (0.58 nm) was synthesized initially by this method. These obtained foams illustrate outstanding mechanical properties and processability which are ideal for adsorption and separation.

The oil-water selective adsorption experiments displayed that such foams obtained highly efficient oil-water separation (up to 99% removal efficiency) with ultrahigh reusability (over100 cycles) and easy recycling. Furthermore, NKCOF-12 with the smallest pore size amongst all the reported eclipsed stacking 2D COFs was built.

NKCOF-12 has been attributed to its even ultramicroporous channel (0.58 nm) and enriched binding sites, and hence it exhibits outstanding C2H2/CO2 separation performance with greater C2H2 purity (99.3%) compared to the benchmark materials.

This work mot only offers a chance for the construction of COF foams through melt polymerization but also considerably progresses the growth of COFs for practical applications.

Journal Reference:

Zhang, P., et al. (2022) Melt polymerization synthesis of a class of robust self-shaped olefin-linked COF foams as high-efficiency separators. Science China Chemistry. doi.org/10.1007/s11426-022-1224-3.