By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 2 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 2 2022In an article recently published in the journal Additive Manufacturing, researchers discussed the effect of fluid flow on the dendritic development and the production of new grains in additive manufacturing.

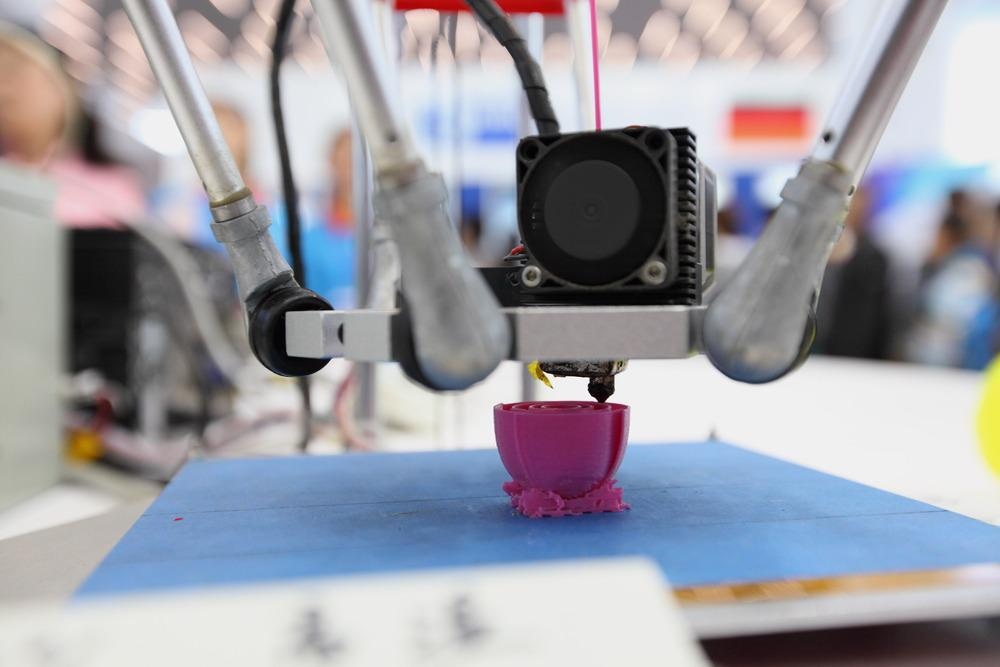

Study: Impact of fluid flow on the dendrite growth and the formation of new grains in additive manufacturing. Image Credit: enmyo/Shutterstock.com

Background

Metal additive manufacturing (AM) generates parts using a three-dimensional (3D) digital model as a guide. However, the successful development of a part with appropriate mechanical characteristics has always been a problem for AM technologies due to a variety of factors that influence grain structure evolution. On the other side, this opens up a lot of possibilities for manipulating grain structure when constructing things with AM.

Regulating grain structure evolution is crucial for the widespread use of AM technology. The nucleation of casting would be aided by the dendritic cracks. Convection would alter the solute distribution ahead of the dendrites, affecting undercooling and the probability of nucleation. However, due to a lack of testing tools for directly witnessing the highly quick solidification process, little effort was put into studying the impact of fluid flow on dendritic growth and the production of new grains under AM conditions.

About the Study

In this study, the authors discussed the improvement of the multi-grid dendrite growth model by two-way coupling with a computational fluid dynamics model to simulate dendrite growth in flowing liquid metal under various temperature gradients and solidification velocities found in AM conditions. The simulated flow velocities at the molten pool boundary were used to determine flow velocities of 0, 0.2, and 0.4 m/s.

The researchers used numerical modeling and experiments to investigate the effect of fluid flow on dendritic growth and the generation of new grains in AM. A computational fluid dynamics (CFD) model was incorporated into the multi-grid dendritic development model, which allowed the fluid flow and dendrite growth to be two-way connected. After that, singletrack tests on Inconel 718 plates were carried out using an electron beam and a laser. The scanning speed and preheating temperature were changed in the proposed experiments to achieve different flow intensities and solidification conditions in the molten pool. The simulation of the molten pool flow and the estimation of the temperature and flow field were done at the same time by using a high-fidelity and thermal-fluid flow model.

The team carried out a two-step numerical modeling examination. In the first stage, the two-way coupled model was used to simulate the dendrite's growth with various orientations in a predetermined fluid flow under varying solidification conditions to highlight the influence of fluid flow on dendrite growth and the creation of new grains.

The flow fields and temperature data extracted from the findings of the thermal-fluid flow modeling were used in the second stage to execute molten-pool size dendritic growth simulations, which was a one-way coupling. The simulation results were then used to describe the grain structure creation mechanism in the experiments, as well as the simulation results and discoveries. The importance of fluid flow was also demonstrated.

Observations

The temperature gradient at the boundary of the molten pool was quite large in case E1 i.e., 0.25 m/s, 425 W, 823 K, the solidification velocity was 0.043 m/s, and the flow velocity was very low. When the temperature gradient was 5 x 106 K/m, the effect of fluid flow on the undercooling distribution was negligible. For cases, S1 i.e., 5 x 105 K/m, S4 i.e., 1.5 x 106 K/m, and S7 i.e., 5 x 106 K/m, the distance between the tallest dendritic tip and the zero-undercooling plane were approximately 21.5, 7.7, and 2.5 m, respectively.

The simulation results showed that fluid flow and solidification influenced dendritic growth and the creation of new grains in AM. The simulation results indicated the extraordinary impact of fluid flow on dendritic growth and the development of new grains in AM, and they also explained the formation mechanism of the grain structure in single-track studies with electron beam and laser.

Conclusions

In conclusion, this study elucidated the development of a dendritic development model with fluid flow to investigate the effect of fluid flow on dendrite growth and the creation of new grains in AM circumstances. The formation of dendrites of various orientations in the flowing liquid metal under varied solidification velocities and temperature gradients encountered in AM were modeled using the two-way coupled model.

The simulation results showed that fluid flow and solidification conditions have a major impact on dendritic growth and the creation of new grains in AM. The flow field and temperature field data extracted from the findings of the thermal-fluid flow modeling were used to run the molten-pool scale dendritic growth simulations.

The authors emphasized that the study of the effect of fluid flow on dendritic growth and the production of possible new grains at the molten pool boundary would be a useful addition to the popular nucleation theory based on solidification velocity and temperature gradient, providing advice for grain shape adjustment.

More from AZoM: What Multi-Analytical Techniques are Used to Assess Paintings?

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Yu, Y., Wang, L., Zhou, J., et al. Impact of fluid flow on the dendrite growth and the formation of new grains in additive manufacturing. Additive Manufacturing102832 (2022). https://www.sciencedirect.com/science/article/pii/S2214860422002317