By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 10 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 10 2022In an article recently published in the journal Additive Manufacturing, researchers discussed the utility of toolpath-based design for the development of carbon-efficient architectural structures by using 3D concrete printing.

Study: Toolpath-based Design for 3D Concrete Printing of Carbon-efficient Architectural Structures. Image Credit: Zapp2Photo/Shutterstock.com

Background

In the future years, the growing global population, combined with the progressive urbanization of developing countries, will drive up the demand for concrete buildings. Design optimization of structural parts is known as one of the primary levers within the concrete and cement value chain to reduce CO2 emissions, alongside advances in material composition and production process.

Due to the challenges and expense of manufacturing sophisticated and customized formworks, structural optimization methods in traditional concrete construction projects are rarely applied. Additive manufacturing (AM) techniques' improved fabrication freedom and automation possibilities can help reduce the emissions of greenhouse gas (GHG) and costs, while also allowing for more innovative design ideas for more suitable concrete construction elements.

3D concrete printing (3DCP) in particular is making inroads in the building business. 3DCP is working to standardize its fabrication process, both in terms of material composition and equipment. This progress, however, has not been matched by developments in digital 3D modeling tools. As a result, design outputs are limited to simple geometries that do not fully use 3DCP's inherent formal flexibility.

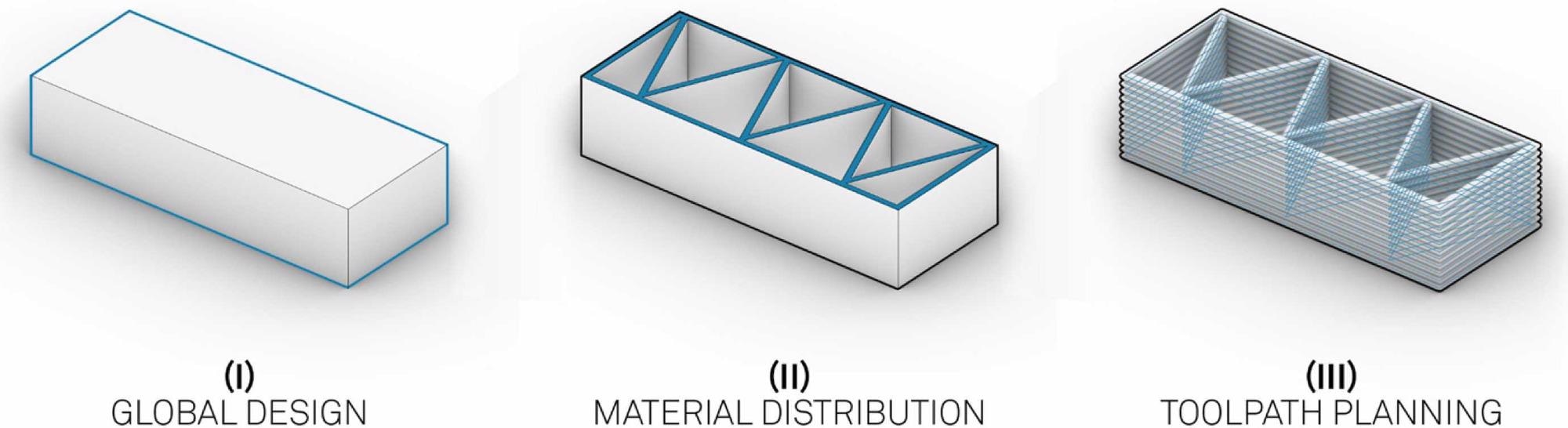

Development scales in a conventional 3DCP design process: (i) design of the global geometry; (ii) engineering of the material distribution; (iii) planning of the printing toolpath. Image Credit: Breseghello, L et al., Additive Manufacturing

About the Study

In this study, the authors proposed a data-driven toolpath-based design approach for 3DCP, which was used to fabricate horizontal architectural structures in a single continuous printing process. The issue of continuous 3D printing in concrete structural beams was addressed by optimization of the design-to-fabrication workflow using a performance-based printing toolpath design method.

The team described an innovative workflow for the design and fabrication of 3DCP structures that incorporated finite element (FE) analysis at multiple stages of development, i.e., layer design optimization through speed variation, the definition of the printing path, and informed reinforcement bar placement. The workflow was validated by designing, fabricating, and testing three-beam designs that gradually included the proposed technologies.

The researchers provided a unique method for designing carbon-efficient 3DCP horizontal structures that integrated toolpath-based modeling and structural optimization procedures. An additive design method was proposed for load-bearing and carbon-efficient horizontal structures. Tension reinforcement was incorporated into 3DCP elements during the printing process. The designed process focused on the print route to include a collection of geometric and structural optimization procedures. The proposed modeling paradigm was put to the test on a variety of building-scale structural beams with various sectional configurations.

Observations

The maximal capacity of B1 was 43.7 kN on average, which resulted in a strength-to-weight ratio of 0.145. The tests on B2 produced an average maximum capacity of 49.9 ±4.2 kN and a weight ratio of 0.216, which was 33% greater than B1. B3, with an average maximum structural capacity of 79.5 ±0.9 kN, had a strength-to-weight ratio of 0.401, which was around 178% more than B1 and 85% higher than B2.

3DCP had intrinsic advantages due to the lack of formwork and the placement of material just where it was operationally necessary. However, at the construction scale, there were just a few instances and applications of efficient design solutions utilizing 3DCP. The impact of the proposed workflow, which enhanced performance by nearly three times between a full beam and the lightest tested beam, could be seen in the strength-to-weight ratio of the three designs.

The increased pressure on the concrete industry to reduce environmental impacts, enhance productivity, safety, and quality, and respond to the worldwide need for new settlements necessitated rethinking design and manufacturing methods in favor of modern automated systems. 3DCP had the potential to automate the manufacturing of extremely efficient concrete structures while it also contributed to the construction industry's long-term sustainability.

The usefulness of the proposed technique was demonstrated by the efficiency of the case studies, as evaluated by the ratio between the strength and weight of the designed solutions. The findings emphasized the necessity of matching design methodologies to fabrication technologies, which paved the way for more structurally and environmentally sound concrete constructions.

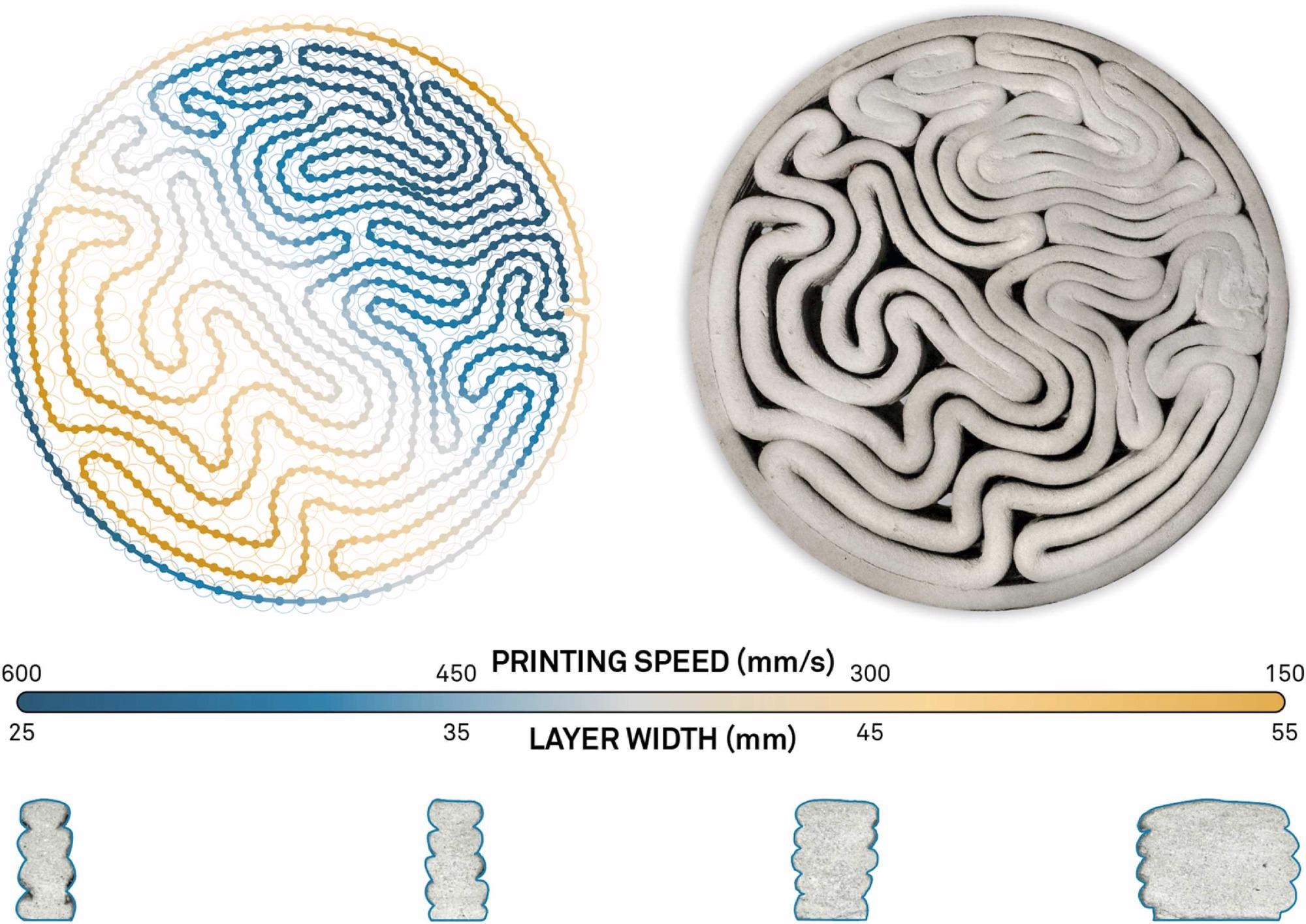

Print test exploring data-informed layer design, linearly varying the density of the space-filling curve and width of the layer using an (X+Y) coordinates values gradient. Image Credit: Breseghello, L et al., Additive Manufacturing

Conclusions

In conclusion, this study discussed the development of the first simple mechanical model for understanding the structural behavior of 3DCP beams and predicting the amount of shear reinforcement required. Using the formal freedom inherent in 3DCP, the proposed approach allowed the design and development of custom-designed structurally efficient parts.

The team developed a new design-to-manufacturing workflow for structurally efficient beam elements that was adapted to the robotic 3DCP fabrication technology, utilizing its major advantages and addressing key barriers to its implementation in industrial applications. The design approach of the presented work relates to the development of the machining toolpath, where fabrication limitations, performance, and aesthetics were linked.

The authors believe that a design approach customized for 3DCP opens the door to more carbon-efficient and environmentally friendly production processes and structures. They also mentioned that the proposed approach will be extended to three-dimensional design spaces, other structural elements, and functionally hybrid constructions in the future.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Breseghello, L., Naboni, R., Toolpath-based Design for 3D Concrete Printing of Carbon-efficient Architectural Structures. Additive Manufacturing 102872 (2022). https://www.sciencedirect.com/science/article/pii/S2214860422002718