Researchers from the University of Minho, Portugal, have investigated current perspectives on the extraction of cellulose polymer fibers from old textiles. Appearing in the journal Polymers, the paper has provided a brief overview of current research in this area.

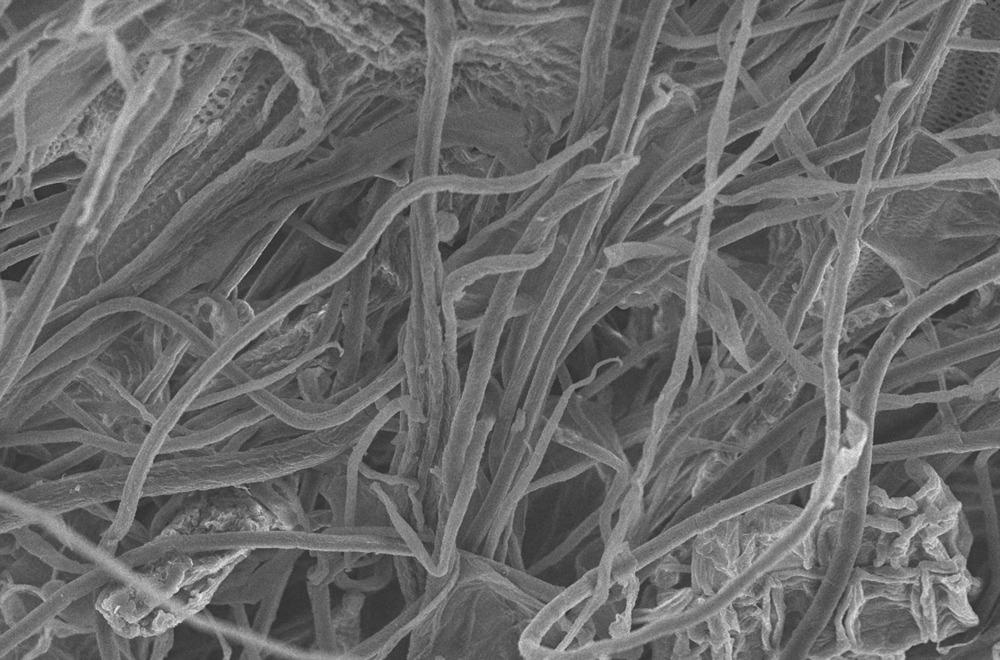

Study: Extraction of Cellulose-Based Polymers from Textile Wastes. Image Credit: TinyPhoto/Shutterstock.com

Extracting Cellulose-Based Fibers

Research into the extraction and exploration of cellulose-based polymers has rapidly become a key area of focus in materials science and the textile industry in recent years. Traditionally, wood has been considered to be the main source of this important material due to its natural abundance. Bleached kraft wood pulp has been one of the most exploited forms in many industries.

However, despite the inherent sustainability of cellulose-based polymer fibers, in the past decade attention has turned to the exploitation of waste materials, especially from the agricultural and textiles industries. Recovering cellulosic materials from these valuable waste streams has the benefits of cost-effectiveness and waste reduction, bringing the production of many commercially useful materials in line with the circular economy concept.

Waste is a key concern in modern industry due to environmental contamination and the depletion of natural resources. Many agricultural and textile wastes are commonly disposed of via landfilling or incinerated to produce biomass and energy. Whilst recovering energy and biomass from waste materials has the potential to improve sustainability, valuable resources which could be used to manufacture other products are lost in the process.

As the demand for cotton-based materials and products has grown, so has pre-consumer and post-consumer waste. With these products exists a significant potential for resource recovery, as finished cotton products contain up to 99% cellulose content, with many impurities already removed during the manufacturing process.

The Study

The special review issue in Polymers has highlighted ten articles that detail progress and developments in the field of cellulose polymer fiber retrieval from waste materials. The paper has received funding from the Portuguese Foundation for Science and Technology.

A Critical Overview of Cotton Waste Fiber Exploitation

A recent critical overview has been conducted by Rizal et al. on cotton waste fibers and processing. The review has provided important perspectives on how cotton waste fiber retrieval and processing methods can mitigate the environmental impact of textiles processing and other industries that use cotton materials and cellulosic fibers.

The paper has explored new work being undertaken to evaluate these materials for functional products, highlighting several applications and exploring different pre-treatment techniques.

Assessing Environmental and Economic Benefits

A recent study by Neto et al. has assessed the economic and environmental benefits of mechanical shredding to retrieve cellulose fibers in a textile company. They have identified aspects that will benefit the circularity of adopting processes. Despite there still being limitations with the technology, the report has highlighted the benefits of manual recycling for this purpose.

Utilizing Different Waste Materials

Different waste materials have been studied in recent research. One study has demonstrated that using a novel silver-nanoparticle modified extraction process to recover cellulosic fibers from citrus sinensis, with the extracted materials effective for removing chromium and cadmium from pharmaceutical effluents.

Rizal et al. have demonstrated using a high-pressure homogenization process to combine extracted cellulose fibers from cotton waste with supercritical carbon dioxide. This enhances the properties of polylactic acid/chitin, and is a green approach for enhancing cellulose nanofiber yields from textile wastes using supercritical carbon dioxide from carpet waste is the focus of recent research. The method produces high-quality, valuable isolates, removing impurities present in the waste material.

Applications of Cellulose Materials Extracted from Waste

The paper has highlighted some of the commercial applications of recovered cellulosic polymer fibers. Regenerated fibers obtained from wastepaper have been utilized in flexible SERS substrates. Modified with gold nanoparticles using spinning methods, the substrate has been successfully used for identifying contaminants in aqueous solutions such as dimetridazole.

Another study has reinforced recycled newspaper fibers with high-density polyethylene. Water resistance and good tensile properties of this material make it beneficial for outdoor applications. Waste banknotes have been explored for use as biofuels such as biogas and bioethanol. Removing ink and treating the materials makes them suitable for biorefinery feedstocks.

Green synthesis methods have been explored for developing cellulose hydrogels for drug delivery purposes. The study by Al-Rajabi et al. has exploited waste oil palm materials. This novel thermo-responsive hydrogel could promote the development of cheap and sustainable drug delivery systems for the biomedical industry.

In Summary

The new review paper has provided a very brief overview of some of the recent developments and perspectives in this emerging field of materials science research. Recovering cellulose-based polymeric materials from agricultural and textile waste products will improve the circularity and economic viability of several industries in the future.

More from AZoM: Metrology in the Digital Era

Further Reading

Felgueiras, H.P. Padrão, J. & Antunes, J.C. (2022) Extraction of Cellulose-Based Polymers from Textile Wastes Polymers 14(10) 2063 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/10/2063

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.