Reviewed by Alex SmithMay 30 2022

As a result of several chemical and physical changes, metals that are subjected to direct exposure to water, air, or other corrosive media are inclined to damage. This results in environmental issues and huge resource waste.

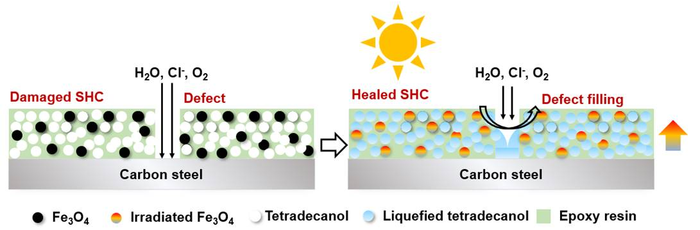

Corrosion Protection Mechanism of The Intact, Damaged and Healed SHCs. Image Credit: Zhifeng Lin, Weihua Li.

Corrosion Protection Mechanism of The Intact, Damaged and Healed SHCs. Image Credit: Zhifeng Lin, Weihua Li.

A safety layer can effectively decelerate the corrosion of the matrix material by separating the metal from an environmental medium. Also, its compactness and corrosion resistance are considered two major factors for the ultimate protective effect.

In comparison to inorganic coatings like ceramics and enamel, organic coatings develop a denser cover on the metal surface. This exhibits an extensive range of sources and good corrosion resistance and is widely used at present.

However, a vital fact is that microcracks are easily developed on the surface of the organic coating under various natural application conditions, thereby enabling the entry of water and other corrosive media.

For this issue to be resolved, the scientific research group of Zhifeng Lin and Weihua Li from Sun Yat-sen University made an epoxy-based coating (measuring a thickness of about 200 μm) with tetradecanol and Fe3O4 nanoparticles.

This displayed self-healing potential under solar irradiation and could safeguard the basic carbon steel (CS) substrate from erosion. The study has been reported in the Frontiers of Chemical Science and Engineering journal.

Self-healing coating (SHC) is a new type of coating that has extended life expectations by repairing microcracks or damage to form a repairable physical barrier, and was firstly reported 20 years ago.

Even though numerous methods could be employed to obtain the self-healing coatings, such as polymer resin self-dynamic bonding, external repair or corrosion inhibitors addition, and thermoplasticity or shape-memory materials usage, UV irradiation or high-temperature conditions are essential to induce chemical reactions. Hence, self-healing coatings obtained under mild conditions are required immediately.

The researchers discovered that the SHC coating could be heated to 70 °C in just 200 seconds under simulated solar irradiation as a result of the photothermal effect of Fe3O4 nanoparticles. This greatly surpasses the melting point of tetradecanol at 37.6 °C.

Also, it was possible to repair the perforations and scratches resulting from the scalpel on the coating surface only after the simulated solar irradiating for around 3 minutes. Its wettability was proved to increase with the addition ratio of tetradecanol which has been attributed to a huge number of polar hydroxyl groups on it.

To witness the performance of SHC coating in real natural surroundings, scientists took the coating scratch-heal experiment under natural outdoor light and eventually obtained the perfect outcomes.

The corrosion safety efficiency of SHC coating on the basic metal substrate could be maintained at more than 99% irrespective of the repair. It could efficiently avoid the infiltration of H2O, O2, and Cl–, and displays good stability and safe performance even after immersion in 3.5 wt% NaCl solution for about 168 hours.

It was possible for researchers to obtain a novel self-healing of anti-corrosion coating under sunlight by choosing the right liquefied phase change materials, and photothermal particles, and mixing them with the right content.

The SHC coating exhibits good photothermal property and has the potential to convert into liquid flow under sunlight for the defects to be filled. The impermeability and anti-corrosion properties are equivalent to commercial coatings and are forecasted to be mass-produced and utilized for corrosion protection in outdoor facilities.

Journal Reference:

Hao, Z.., et al. (2022) Anticorrosive composite self-healing coating enabled by solar irradiation. Frontiers of Chemical Science and Engineering. doi.org/10.1007/s11705-022-2147-1.