A team of researchers from Hungary and India has investigated the qualities and properties of PLA biocomposites incorporating wood waste. The paper has appeared in the journal Polymers.

Study: Thermal and Sliding Wear Properties of Wood Waste-Filled Poly(Lactic Acid) Biocomposites. Image Credit: czjiri/Shutterstock.com

Biocomposites

The urgent need to mitigate the impact of anthropogenic climate change and reduce waste streams has led to intense research focus in recent years. Synthetic plastic waste is a vast challenge, as the majority of the 320 million tons of waste produced per year end up in the ocean, landfills, or is incinerated.

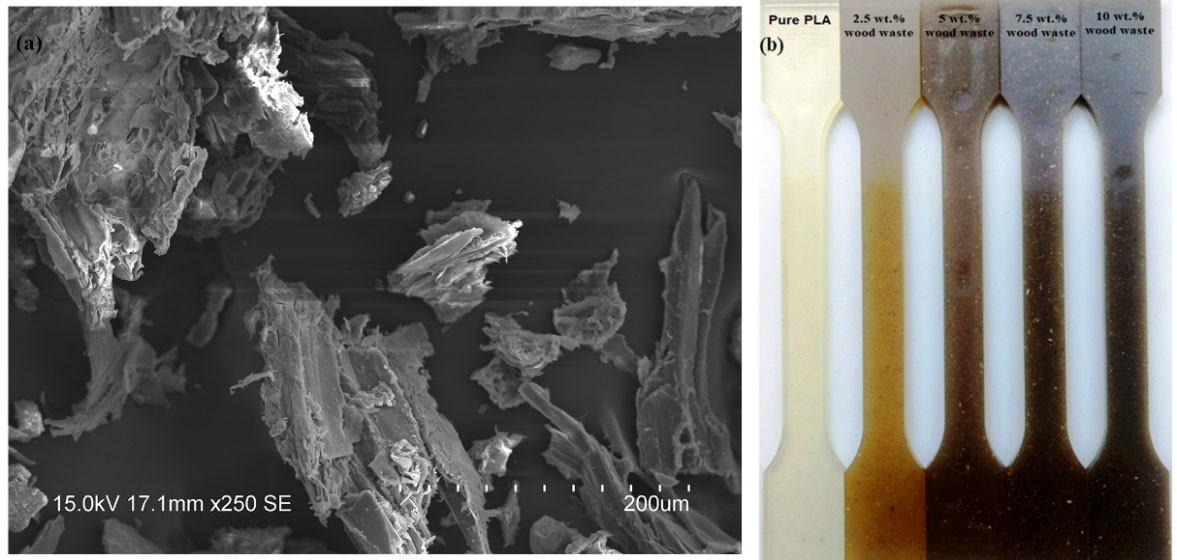

(a) SEM micrograph of North Indian rosewood waste, (b) fabricated biocomposites. Image Credit: Singh, T et al., Polymers

Aside from synthetic plastics, another key issue is the safe disposal of agricultural and forestry waste. Wood manufacturing alone generates almost fourteen million tons of solid wood waste annually. Valorizing both synthetic plastic and wood waste to create useful products offers the potential to significantly reduce the environmental harm caused by numerous industries and reduce dependence on virgin resources.

Biocomposites are a key area of research in materials science due to the advantages they offer over traditional materials. They have shown potential for applications in various industries such as the automotive industry, construction, consumer products, and aerospace.

The global biocomposite industry’s market size in 2016 was $16.46 billion, and this figure has been predicted to grow to $36.76 billion by this year. This represents a CAGR of 14.44%.

Several studies have investigated the properties of biocomposites that incorporate organic waste such as sugarcane, maize hull, rice husk, and wood waste. Other studies have investigated the properties of industrial wastes such as copper slag. Mechanical properties, biodegradability, toxicity, ecotoxicity, antibacterial, and thermal properties of various waste materials have been extensively evaluated.

PLA

Poly(lactic acid) or PLA has piqued the interest of researchers in recent years for use in biocomposites. This organic polymer possesses several advantageous properties such as biodegradability, non-toxicity, and good mechanical properties. This biopolymer can be used for a variety of purposes, such as biomedical materials, packaging, and textiles.

There are, however, some drawbacks to this material, including poor thermal stability, relatively high cost, poor impact resistance, and rapid aging. However, these drawbacks can easily be overcome by using fillers and reinforcements, blending, and copolymerization.

Several papers have been published in recent years on improving the properties of PLA. Incorporation of materials such as hemp, alkali-treated walnut shells, nettle fibers, solid wood, and woven fabric have all been reported. Research has demonstrated various modifications to the quality and performance of PLA-based biocomposites.

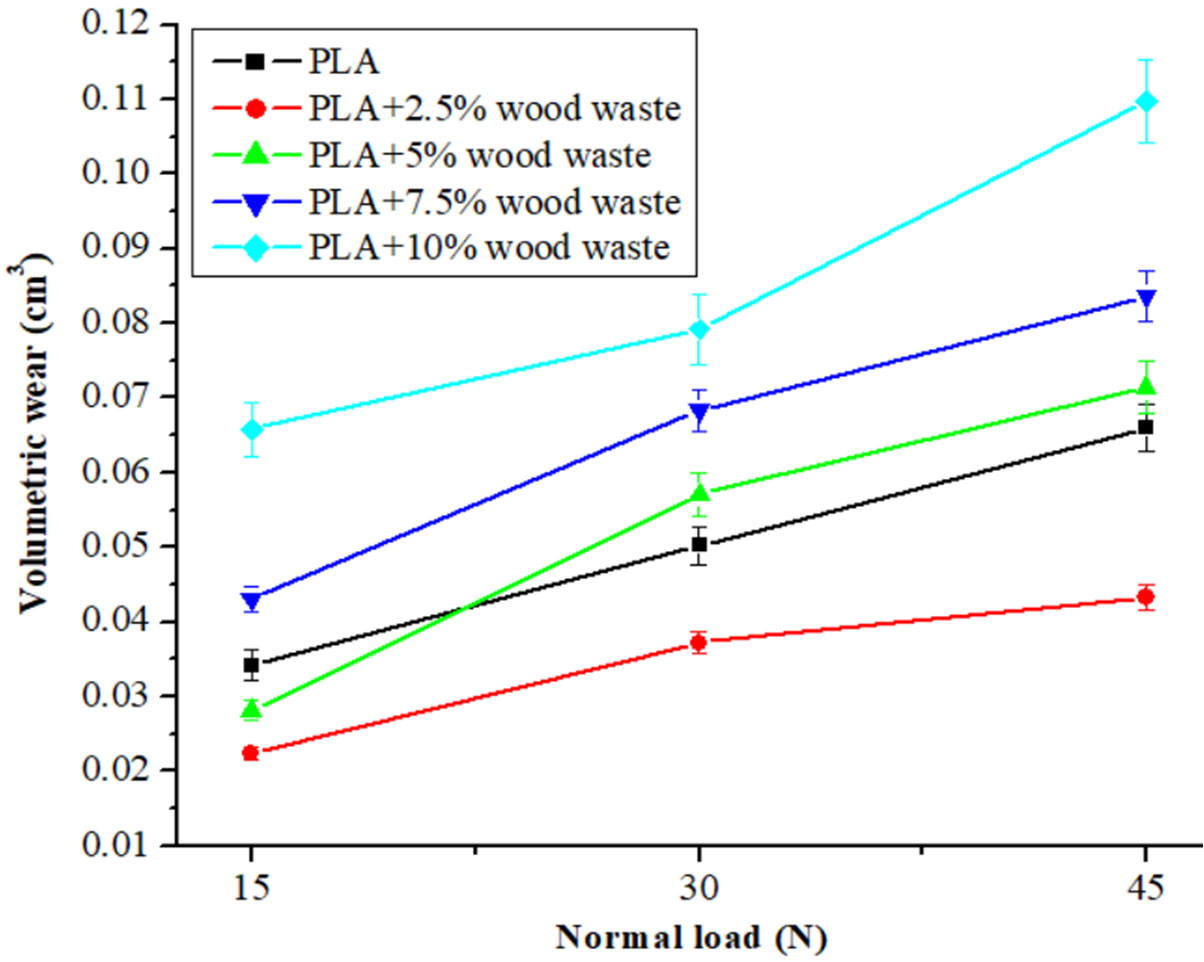

Volumetric wear of composite as a function of normal load. Image Credit: Singh, T et al., Polymers

The Study

Recent research has reported that wood waste impacts the thermal, physical, thermo-mechanical, and mechanical properties of PLA-based biocomposites. However, there has been no study on the sliding wear behavior of these biocomposites. However, some studies have indicated that using biocarbon and natural fibers in composites enhances their wear resistance.

The study has investigated the influence of wood waste on the dry sliding wear and thermal properties of PLA-based biocomposites. Specifically, the authors investigated North Indian rosewood waste.

Samples were prepared with different wood waste percentages, ranging from 0-105 wt. Biocomposite wear was analyzed under different dry contact conditions with different parameters. Sliding velocity and normal load parameters at a fixed sliding distance were used to elucidate wear information.

The biocomposite samples were analyzed using the Taguchi method to provide information on sliding wear behavior. Wear increased as sliding velocity and load increased. However, compared to pure PLA, the wood waste-biocomposites displayed up to 38% wear reduction.

The thermal stability of the prepared PLA biocomposites was affected by the inclusion of wood waste. Using this waste material decreased this property and was confirmed using thermogravimetric analysis.

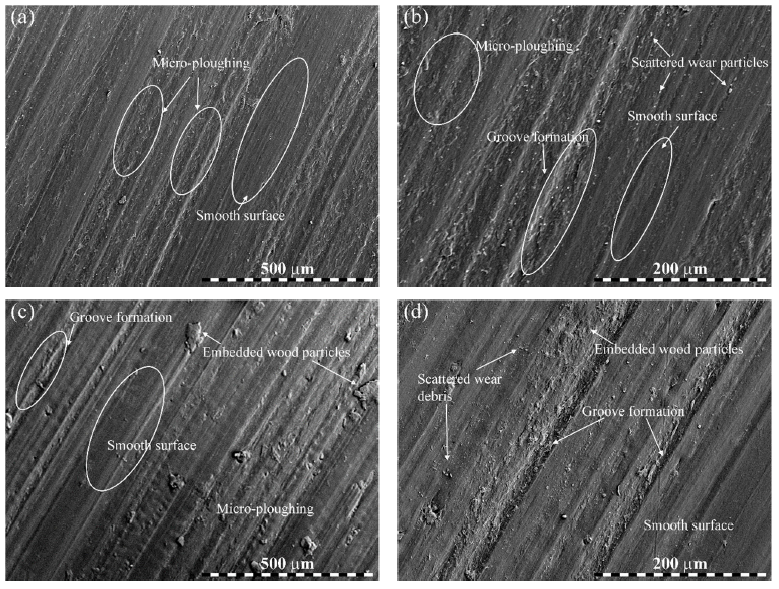

The authors employed scanning electron microscopy to examine the biocomposite surface wear. Wear results were correlated with wear mechanisms in the composite’s surface structure. Moderately rough worn surfaces were revealed, with micro-ploughing, scratching, damage, and poor interfacial bonding revealed using SEM.

Worn micrographs of biocomposites: (a,b) bare PLA and (c,d) 2.5 wt.% wood waste‐filled biocomposites at lower and higher magnification. Image Credit: Singh, T et al., Polymers

In Summary

The authors have thoroughly investigated the sliding wear and thermal properties of Indian rosewood waste/PLA biocomposites. Their results have demonstrated that these biocomposites have reduced thermal stability and have revealed the surface wear characteristics under various experimental conditions. Whilst challenges exist with these materials there are opportunities for future research to address them.

The need for biocomposites to reduce synthetic plastic and organic waste and address the challenges of climate change has led to increased research focus in the field of materials science. These materials offer benefits in terms of biodegradability, non-toxicity, and sustainable production. The research has provided crucial information for future research into the performance and design of these important composite materials.

Further Reading

Singh, T et al. (2022) Thermal and Sliding Wear Properties of Wood Waste-Filled Poly(Lactic Acid) Biocomposites Polymers 14(11) 2230 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/11/2230

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.