A team of researchers from Italy has authored a new paper considering how to improve the circularity of oil refineries, in particular reusing by-products of the oil industry. Their research has appeared in the journal Energies.

Study: Analytics for Recovery and Reuse of Solid Wastes from Refineries. Image Credit: Avigator Fortuner/Shutterstock.com

Oil Refinery Products

Currently, there are over five hundred oil refineries in operation across the world. Despite the growing market share of renewable energy and the phasing out of fossil fuels, there are still uses for the products of oil refineries. Asphalt (also called bitumen,) pet-coke, and pitch are three semi-solid/solid products that are crucial for many industries, and their use is predicted to continue.

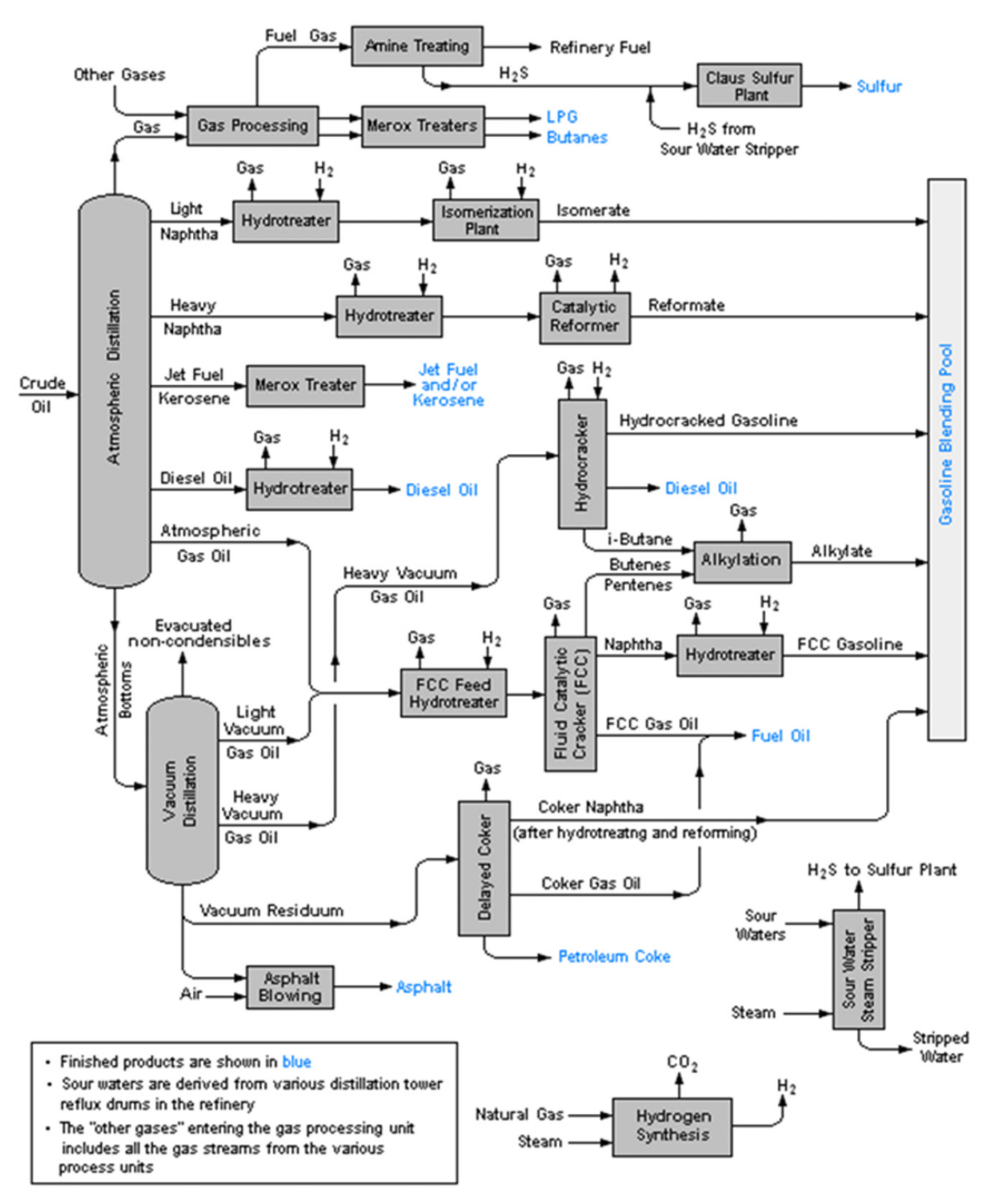

From Wikimedia Commons, the free media repository https://commons.wikimedia.org/wiki/File:RefineryFlow.png (accessed on April 2022). Permission is granted to copy, distribute and/or modify this document under the terms of the GNU Free Documentation License, Version 1.2 or any later version published by the Free Software Foundation.

By-products are produced by refineries at various stages during crude oil processing. Pet-coke, a solid carbonaceous product, is produced from the residues of vacuum distillation units. This product can contain sulfur and metals such as vanadium and nickel, depending on the oil’s composition.

Asphalt is also produced during vacuum distillation. This highly viscous, sticky, black material remains liquid when transported hot and solidifies as it cools. Asphaltene, which asphalt is derived from, is the heaviest fraction of crude oil.

The general term “petroleum pitch” is applied to heavy refinery products produced in other units in delayed cokers, which are semi-solid or highly viscous. These products can be enriched with metals such as nickel, molybdenum, and vanadium. Units where petroleum pitch is produced include catalytic units and hydro-catalytic units.

Asphalt is primarily used as a construction material, where it is mainly used in road surfaces. It is also used as a fuel. Pet-coke is used for various applications depending on quality: sulfur-rich, low-grade pet-coke has found use as a substitute for coal in cement production, steelmaking, and electricity generation. High-grade coke is used as raw materials in steel and aluminum production.

Refinery by-products are in huge demand across the world. Twenty million barrels of US pet-coke were exported to world markets in 2019, with ten million barrels of US asphalt exported in the same year.

The Study

The study has explored current perspectives on carbon-enriched oil refinery by-products to investigate how the oil refinery industry can improve the circularity of products. One hundred and twenty-nine studies in the current literature have been analyzed by the authors. Whilst brief, the review has attempted to comprehensively evaluate the use of petroleum as a chemical feedstock.

The oil refinery industry has implemented the waste-to-energy concept, where low value waste products are converted into high-value energy generation, reducing the exploitation of virgin oil, gas, and coal resources, and consequently reducing the carbon footprint of power generation.

Carbon capture and storage (CCS) technologies have received increased research attention in recent years and provide potential benefits for the recovery of carbon and utilizing waste emissions and products to manufacture value-added products. The oil refinery industry can benefit from CCS technologies, especially chemical looping combustion, which is especially useful for pet-coke and metal-rich residues.

Another CCS technology that has been developed in recent years is CarboLoop. In this method, solid carbon acts as both a fuel and oxygen carrier. Metals in metal-rich products can function as oxygen carriers, making this a chemical looping combustion method with immense potential for improving the circularity of oil refineries.

![Nanostructured carbon material produced from Pitch pyrolysis at 1800 °C. (a): SEM images and, in the indent, morphology of produced char; (b) Raman spectra (from [34]).](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_59224_16540769482905014.png)

Nanostructured carbon material produced from Pitch pyrolysis at 1800 °C. (a): SEM images and, in the indent, morphology of produced char; (b) Raman spectra. Image Credit: Apicella, B et al., Energies

Understanding the Chemical Structure of By-products

The authors have stated that to valorize heavy petroleum fractions such as pet-coke, asphaltenes, and pitch, a detailed understanding of their chemical structure is necessary. Understanding the chemical structure of these products is fundamental for controlling the properties of products. Research has indicated that key properties are aromaticity, molecular weight, and chemical functionalities.

Effective analysis of these properties is central to the development of new products. This requires powerful analytical techniques. The review has proposed that FTIR and Raman spectroscopy, size exclusion chromatography, and mass spectrometry are the most suitable methods for the analysis of these properties. Many studies have used different analytical techniques in recent years.

Pet-coke has been proposed as a promising fuel for energy generation due to its high carbon content, low ash, and enhanced heating value. The authors have stressed the need to perform thermochemical conversion behavior analysis on new fuels produced from oil refinery by-products and waste materials.

Residual metals are abundant in oil refinery waste products. The authors have indicated that research on these components and their impact on the properties and behavior of products should play a role in future research on improving the circularity of waste products in oil refineries. Indeed, some studies have already investigated the effects of residual metals in oil refinery by-products.

![Spectra of two different petroleum pitches with different softening points (PP118, Tsoftening = 118 °C and PP250, Tsoftening = 250 °C), acquired by LDI-TOF MS adapted from [52] with permission.](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_59224_16540769633624764.png)

Spectra of two different petroleum pitches with different softening points (PP118, Tsoftening = 118 °C and PP250, Tsoftening = 250 °C), acquired by LDI-TOF MS. Image Credit: Apicella, B et al., Energies

In Summary

Circularity has become increasingly central to future refinery design and operation, with increasing interest in new processes and value-added products produced from by-products such as carbon nanomaterials from pitch for use in products including electrodes and batteries. The new review has explored several current and future perspectives and, whilst brief, provides a solid knowledge base for future research.

Further Reading

Apicella, B. Russo, C & Senneca, O (2022) Analytics for Recovery and Reuse of Solid Wastes from Refineries Energies 15(11) 4026 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/11/4026

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.