Researchers from Chile and the UK have collaborated on a new paper in the journal Materials exploring the use of agar in biodegradable packaging. The paper has important implications for reducing the environmental damage of plastic packaging.

Study: Agar Biopolymer Films for Biodegradable Packaging: A Reference Dataset for Exploring the Limits of Mechanical Performance. Image Credit: Mohammed_Al_Ali/Shutterstock.com

Bioplastics: Overcoming the Issue with Plastic Waste

Plastic waste has become a critical issue in the 21st century. Ever since the widespread commercial development of plastic products in the mid-20th century, the amount of waste in the environment has grown to staggering proportions. Synthetic polymers possess low biodegradability, and their breakdown by physical, chemical, and microbial methods in the environment leads to toxic by-products.

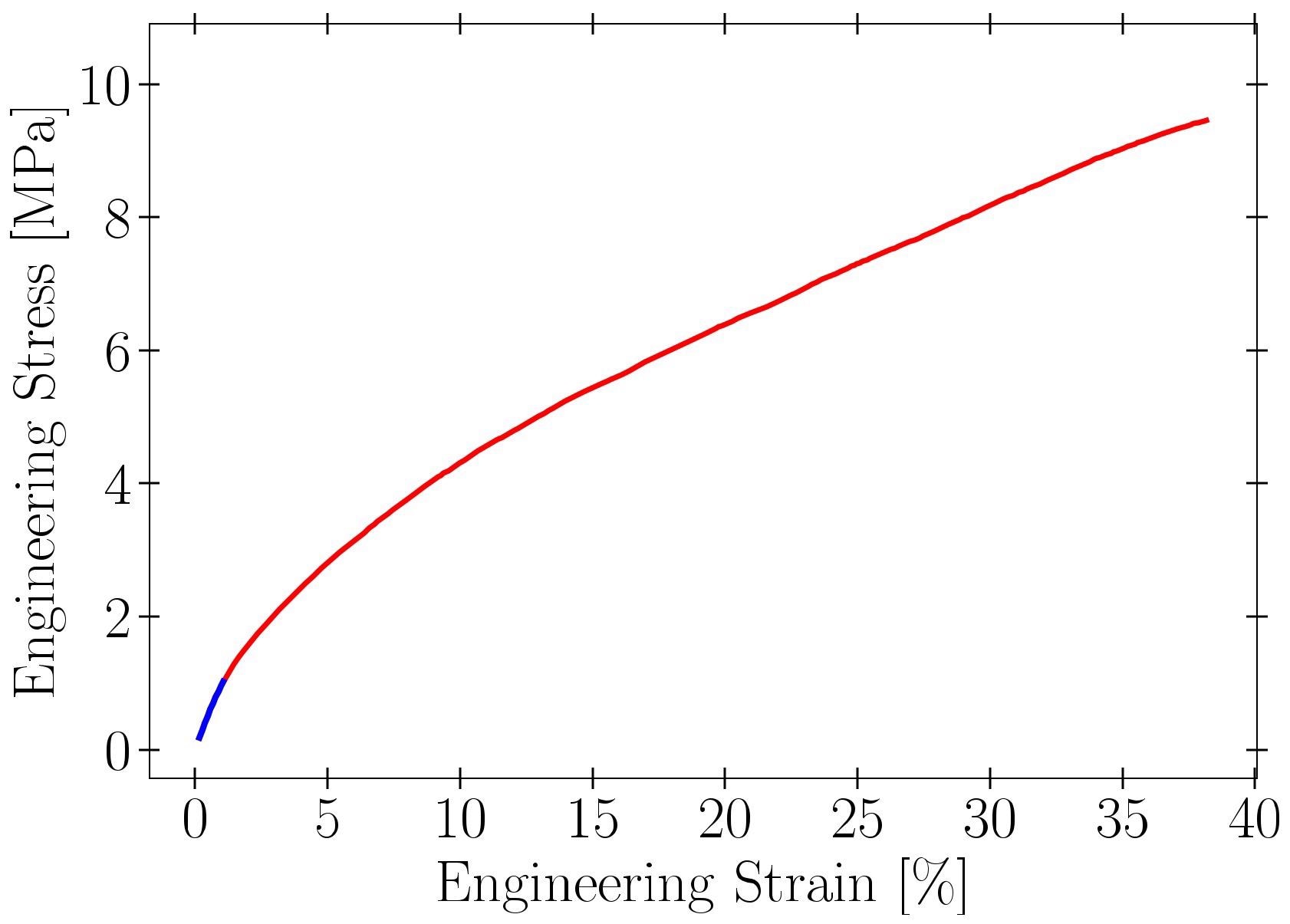

Average engineering stress as a function of engineering strain for a concentration of 2% agar and 1.25% glycerin. The blue line represents the linear portion or elastic zone, and the grey shaded region corresponds to the experimental error. Image Credit: Hernández, V et al., Materials

Plastic production is extremely energy-intensive. Manufacturing processes emit vast quantities of harmful greenhouse gas emissions. Plastic packaging, whilst being lightweight, cheap, and with favorable mechanical properties, represents around half of all marine plastic pollution. In 2018 alone, 259 million tons of plastics were manufactured, and by 2050, it is predicted that plastics will account for 20% of all oil consumption.

To overcome these issues, bioplastics have been widely proposed. These bio-based polymers offer benefits of biodegradability, non-toxic by-products, and reduced emissions during manufacture. Moreover, they can be produced from renewable feedstocks. However, there is one critical issue with bioplastics. Their raw materials can compete for land with food and animal feed crops.

Using Seaweed for Bioplastic Production

One strategy which addresses the issue of land use is to produce bioplastics from marine organisms. Seaweed has been evaluated in recent research for the production of these commercially important green materials.

Seaweed is a beneficial, sustainable bioplastic source as organisms do not require fresh water, fertilizer, or arable land to grow. Moreover, these organisms function as a carbon sink, making bioplastic production from seaweed a carbon-neutral process.

Several studies have demonstrated the use of seaweed species to produce a wide range of biopolymers and bioplastics. Researchers have extracted useful substances such as carrageenan, agar, alginate, starch, algal proteins, and cellulose. These products have been employed in the production of packaging, thin films, and coating. Packaging made from seaweed extracts biodegrades rapidly in soil.

![Linear portion of mechanical properties as a function of different concentrations of agar–glycerin percentages. The mechanical properties are the Young’s modulus (left column), elongation at break (mid column) and ultimate tensile strength (right column) for low (top row), medium (mid row) and high (bottom row) agar and glycerin concentrations. The regression coefficients for mechanical properties [Equation (S1)] are given in Supplementary Materials.](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_59250_16542514492378316.jpg)

Linear portion of mechanical properties as a function of different concentrations of agar–glycerin percentages. The mechanical properties are the Young’s modulus (left column), elongation at break (mid column) and ultimate tensile strength (right column) for low (top row), medium (mid row) and high (bottom row) agar and glycerin concentrations. Image Credit: Hernández, V et al., Materials

The Study

The new paper has studied the use of agar in biodegradable, sustainable bioplastics. Whilst there has been plenty of research on using agar in composites, there has been little attention on agar alone. Currently, there is a lack of understanding of how agar influences the mechanical properties of bioplastics in combination with plasticizers.

Some studies have indicated that pure agar films are brittle, but they only focus on a few simple formulations of agar and plasticizers such as sorbitol. The main focus in research currently is on more complex formulations and their performance. The authors have noted that a comprehensive understanding of agar-based biofilms for packaging is hindered by the current lack of data.

The authors have analyzed the performance of agar-based biopolymer films. Agar-glycerin biopolymers with varying concentrations of components were evaluated for their strength, ductility, and elasticity. These three properties are central to the design of effective packaging.

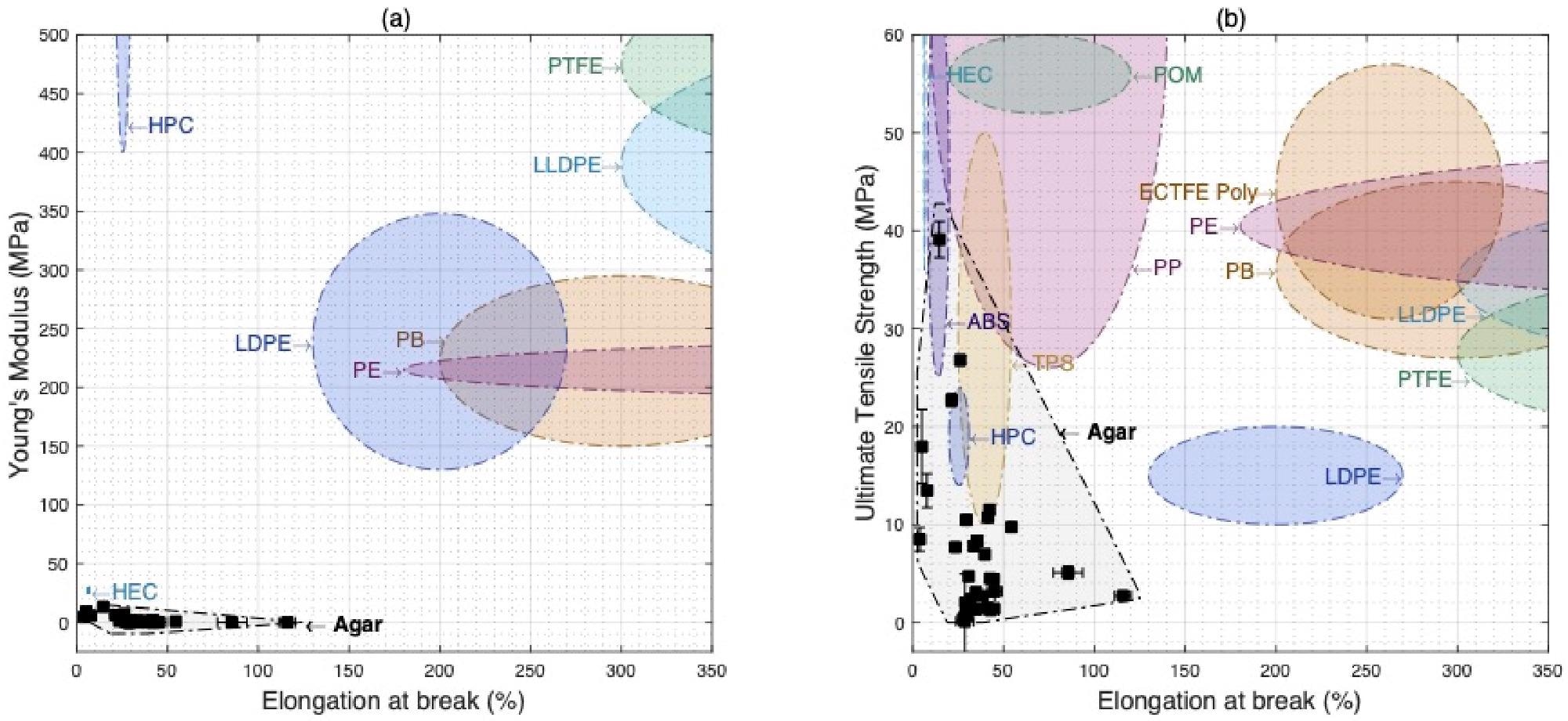

To evaluate their performance and potential for commercial applications, the analysis results were compared to previous studies on more complex agar-based biopolymers with ingredients such as inorganic and organic nanoparticles, oils, and other biopolymers. Additionally, the proposed biofilm properties and performance were compared to commercially available synthetic polymers.

A neural network was trained by the authors using the experimental dataset to predict elongation at break, ultimate tensile strength, and Young’s modulus of the prepared bioplastics.

Study Findings and Conclusions

The authors discovered that systematic variation of agar and glycerin in the bioplastic samples produced tensile properties that were comparable to more complex formulations. Regarding synthetic plastics, the authors found that select formulations of agar-glycerin bioplastics possess comparable tensile properties to PP, TPS, and ABS, three commercially available plastic packaging materials.

Material selection charts comparing agar biopolymer films to commercial polymer systems, illustrating (a) Young’s modulus versus elongation at break, and (b) ultimate tensile strength versus elongation at break. Image Credit: Hernández, V et al., Materials

Comparing the results of their experiments to agar-based films currently being researched, the authors discovered that there is a potential for using additives and additional processing steps to further improve properties such as Young’s modulus. The simplicity of the process techniques and composite formulation presented in the research provides a promising research direction for the future of seaweed-based bioplastics.

Aside from mechanical performance, which has been covered in this study, bioplastic packaging needs to possess other important properties such as water vapor permeation, solvent resistance, and antimicrobial properties. This is outside the scope of this research, and the authors have stated that this will be an advantageous future research direction for agar-based biopolymers.

Summing up, the paper has provided a solid foundation for future research in the field of agar-based bioplastics. Whilst challenges still exist in the area, the authors have highlighted the importance of a data-driven approach to research, bioplastic design, and workflows. This approach will expedite the development of sustainable, seaweed-based bioplastics to replace current environmentally harmful plastic packaging.

Further Reading

Hernández, V et al. (2022) Agar Biopolymer Films for Biodegradable Packaging: A Reference Dataset for Exploring the Limits of Mechanical Performance Materials 15(11) 3954 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/11/3954

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.