There has been growing interest in using new, cheaper raw materials for the production of biodiesel to meet the economic challenges associated with its manufacture. Writing in the journal Energies, scientists from Vytautas Magnus University in Lithuania have reviewed recent research progress in the utilization of microalgal biomass, a cheap, sustainable resource, to produce biodiesel.

Study: Application of Microalgae Biomass for Biodiesel Fuel Production.Image Credit: Maryna Lahereva/Shutterstock.com

The Benefits of Microalgal Biomass

There has been growing interest in utilizing algal biomass for the manufacture of several products. This valuable resource has been explored for use in the food industry, pharmaceutical industry, and biofuel industry.

Microalgae can be cultivated on land which would otherwise be unsuitable for food production. Moreover, microalgal biomass can be grown on non-arable land, avoiding issues with using land that is needed for food production. Furthermore, wastewater sources can be used for microalgal production. This avoids the use of water that is otherwise needed for drinking and crop irrigation.

Compounds such as carbohydrates, lipids, and pigments can be produced from microalgal biomass, making it an attractive source of raw materials for many industries. Moreover, the high accumulation of biomass with the minimum of land and water use makes this resource a significant research target for industry.

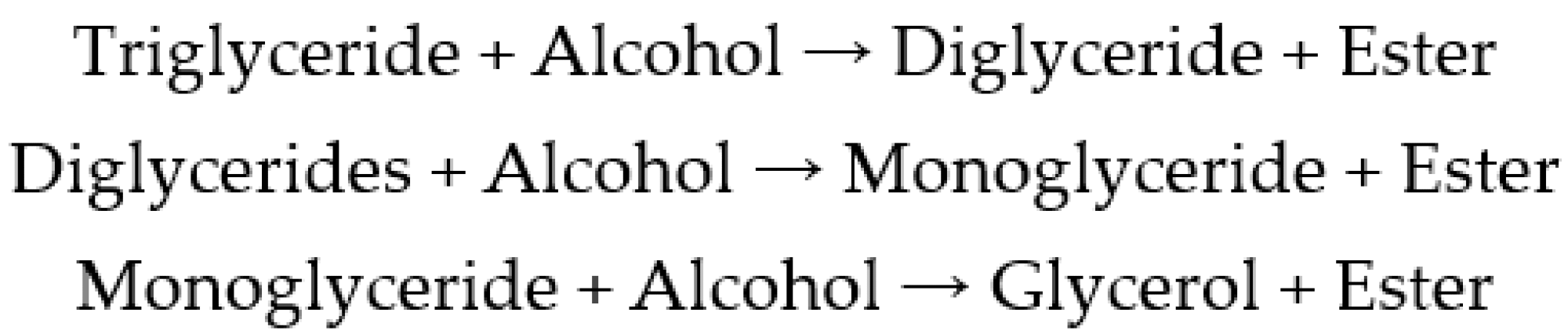

Oil transesterification reaction. Image Credit: Makareviciene, V & Sendzikiene, E, Energies

Using Microalgae for Biodiesel Production

Biodiesel has been proposed as a replacement for conventional fossil fuel-derived diesel. Food crops such as sunflower and rapeseed are commonly used to produce biodiesel, and their use consumes valuable resources such as land and water. Due to high lipid contents, microalgae have been proposed as a resource for biodiesel production.

There are challenges with utilizing this valuable raw material for biodiesel synthesis, however. Issues with high energy and material costs for cultivation and processing exist, and oils produced from microalgal biomass are still unable to compete with mineral oils. Because of these issues, there has been an intense research focus in recent years on improving the efficiency and reducing the energy-intensiveness of microalgal biodiesel production.

The Study

The new study has reviewed current research into synthesizing biodiesel from microalgal biomass. A brief overview has been given on preparation, transesterification, and oil synthesis technologies. In particular, attention has been given to the parameters which influence the efficiency of transesterification processes and resultant biodiesel yield.

The economic efficiency of biodiesel synthesis has been explored in the review, as well as the environmental, physical, operational, and chemical properties of microalgal biodiesel. One hundred and seventy-two papers in the current literature have been reviewed by the authors.

Review Findings

Several findings have been presented in the review, providing perspectives on current research and technologies in the field of microalgal biodiesel synthesis.

The authors have identified that there are certain specificities that govern the production of biodiesel from microalgae. The presence of cell walls in microalgal cells requires methods that break them down before oil extraction can occur. Mechanical and non-mechanical methods have been explored, with high-efficiency methods such as microwave treatment and ultrasonication receiving significant research attention.

Methods to break down cell walls can be used in combination with methods for transesterification and oil extraction. However, due to the presence of elevated levels of saturated fatty acids and free fatty acids compared to traditional vegetable oils, direct transesterification using alcohols and alkaline catalysts is unsuitable. Free fatty esterification methods using organic and mineral acid catalysts are required.

Homogenous catalysts such as hydrochloric acid and sodium hydroxide are commonly used for oil transesterification. Heterogenous catalysts have received attention in recent years, such as metal oxides.

Enzymatic preparations of heterogenous catalysts have shown particular promise for the synthesis of biodiesel from microalgae. These preparations provide simultaneous esterification of free fatty acids and transesterification of triglycerides. However, using enzymatic catalysts is expensive, so research has focused on regenerating and reusing them.

Recent research has demonstrated that the performance characteristics of microalgae-derived biodiesel are almost comparable to conventional biodiesel. Studies have demonstrated that an 80:20% mineral diesel/microalgae biodiesel mixture significantly reduces harmful exhaust emissions and has additional benefits such as maximum rise pressure rates.

Future Trends

The review has highlighted that currently, microalgae-derived biodiesel cannot compete with mineral oil diesel economically. Drawbacks such as higher energy and material costs hinder the widespread commercialization of this green fuel alternative.

Future strategies which can improve the competitiveness of microalgae biodiesel include co-production of valuable chemical products, simultaneous cultivation of valuable food resources such as fish and shellfish, and microalgae cultivation in other technologies. These include biogas production and upgrading and wastewater treatment. The authors have proposed these as future research focuses.

Further Reading

Makareviciene, V & Sendzikiene, E (2022) Application of Microalgae Biomass for Biodiesel Fuel Production Energies 15(11) 4178 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/11/4178

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.