Scientists from China have collaborated on a paper in the journal Polymers investigating the use of basal fiber composites in clean energy technologies. The paper discusses basalt fiber chemical composition, production methods, properties, and more.

Study: A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids. Image Credit: porti/Shutterstock.com

What is Basalt Fiber?

Many materials have been evaluated in recent years for use in sustainable technologies such as green energy generation. These fibers are produced from naturally occurring basalt ores using methods such as melting and drawing at hot temperatures. Their manufacture and use do not emit harmful greenhouse gases or present toxicity to humans or the environment.

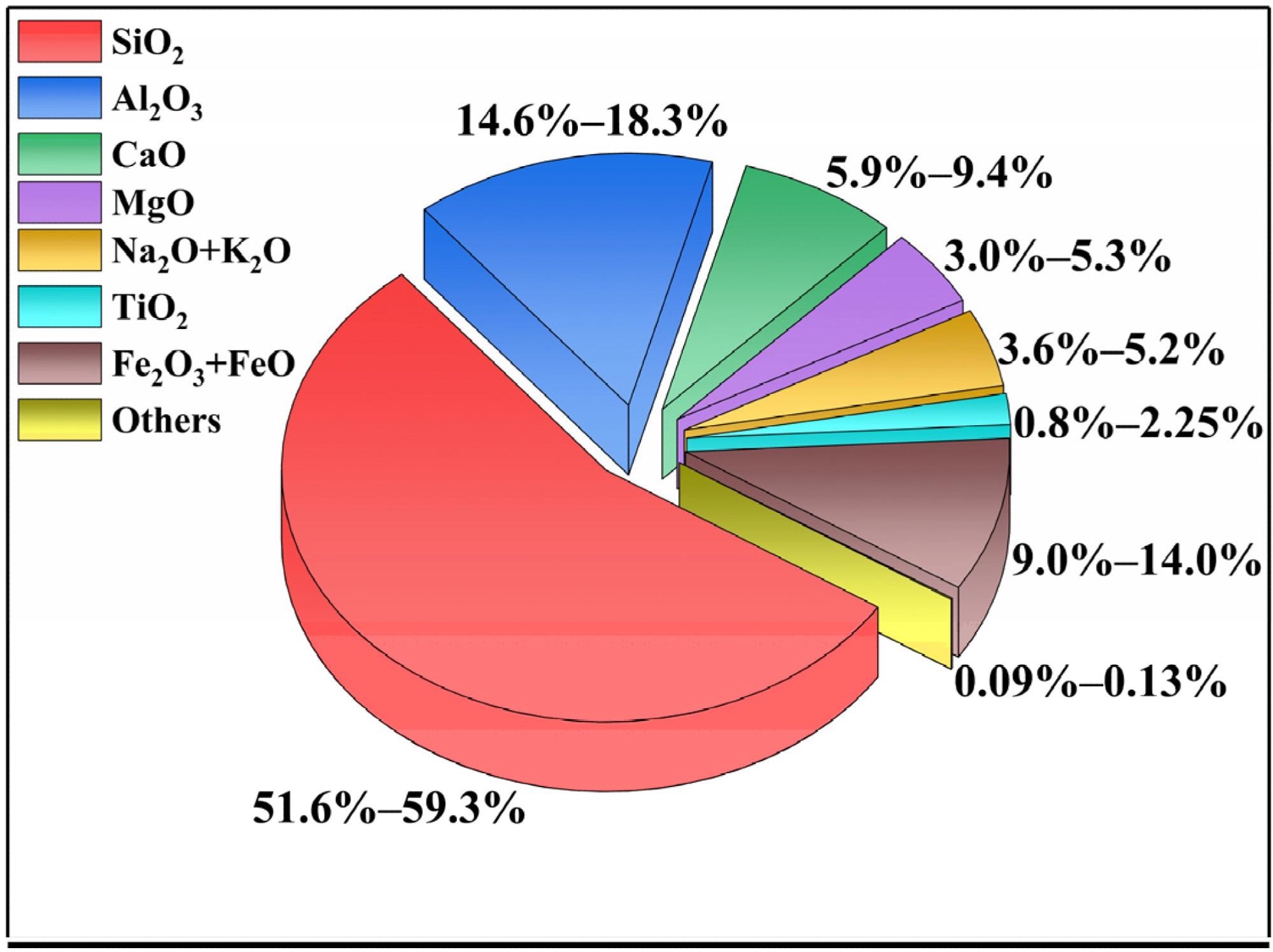

Chemical composition of basalt fiber (BF). Image Credit: Liu, H et al., Polymers

Compared to carbon fibers, basalt fibers have a lower cost and they have better mechanical properties than glass fibers. Due to their advantages, they have been extensively investigated for use in sectors such as aerospace, construction, shipbuilding, and the petrochemical industries.

Proposed in 1922, it was not until the mid-1980s that the industrial production of basalt fibers was realized in Ukraine. Initial attempts to manufacture basalt fibers suffered from poor production processes, high energy demands, and complex equipment infrastructure. Progress was made in the 1990s, with production process efficiency and energy use improvements made.

China played a key role in basalt fiber manufacture in the early 21st century, producing several products from this material. Companies involved in basalt fiber research and manufacture today include Russia’s Kamenny VeK and the Hengdian Group in China.

Using Basalt Fiber in the Energy Industry

Glass fiber composites are commonly used in the energy industry for the manufacture of critical electrical equipment such as conductors, cross-arms, and insulated pull rods. However, increasing voltages and capacities of generators place demands on components that glass fiber composites cannot adequately satisfy.

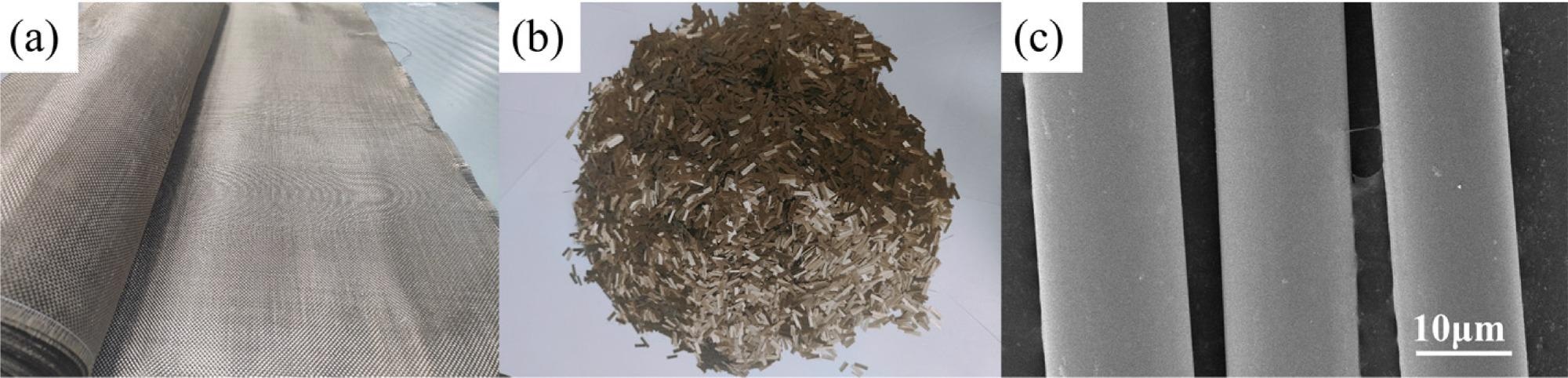

Shape and appearance of BF, (a) BF sheet, (b) short-cut BF, and (c) scanning electron microscopy image of BF. Image Credit: Liu, H et al., Polymers

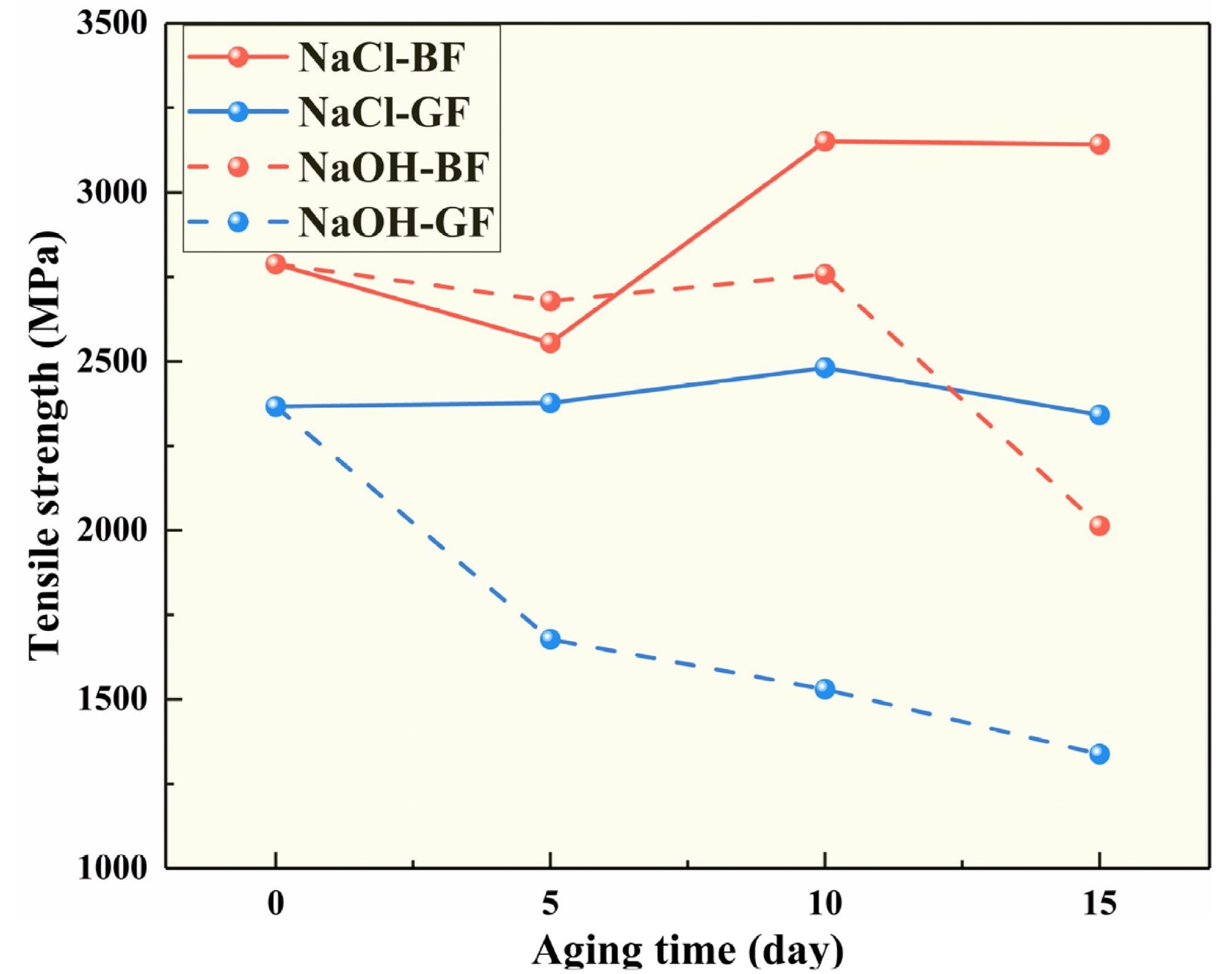

Drawbacks to these materials include low elastic modulus, their brittle natures that make them vulnerable to cracking, and rapid aging in humid and hot environments. Severe corrosion of components manufactured from glass fiber composites can occur in power plants, severely limiting their efficiency and serviceable life.

In wind turbines, glass fiber composites have been shown to possess inadequate mechanical properties, especially at blade lengths over 40 m. This leads to increased chances of critical failures and more regular maintenance needs.

Basalt fibers, with their low cost and superior mechanical properties, have been proposed in recent years to meet the demands on components in power generation technologies. Higher fatigue and corrosion resistance, higher elastic modulus compared to glass fiber, low weight, and lower energy consumption are benefits of basalt fibers that make them ideal choices for these applications.

There are several technical challenges to overcome with basalt fibers before they can be considered for widespread commercial application in the energy industry, however. These include poor stability of products, insufficient production standardization, and inadequate equipment.

The Study

The new paper in Polymers has investigated several key factors in basalt fiber production and use in applications for the energy industry. The study covers basalt fiber composition, production processes, properties, modification methods, interface problems, and innovative applications of basalt fibers in clean power grids and the green energy sector. The paper aims to aid the acceleration of basalt fiber uptake in the clean energy industry.

Salt alkali aging test results of different fibers. Image Credit: Liu, H et al., Polymers

Study Findings

Several key findings and conclusions were made in the study. Additionally, the authors highlighted several prospects for basalt fibers in the energy industry that could inform future research in the area.

Basalt fibers possess comprehensive performance characteristics and enhanced eco-friendliness compared to some traditional materials used in power stations and electricity grid applications. Previous research has focused mainly on applications, without sufficient examination of the high strength and stabilization of basalt fibers.

Mineral composition, melting properties, and chemical composition influence the performance characteristics of basalt fiber, and optimizing these characteristics confers improvements in production processes and, consequently, the properties of products produced with basalt fibers.

Interface interaction mechanisms in basalt fibers are highly complex, often acting in conjunction, and affected by various forces. Several modification methods exist which can improve composite bonding properties.

Basalt fiber, due to its many advantageous properties, can meet the demands of the green energy sector for use in critical electrical components. Further research into the materials and industrialization processes is critical.

The authors have recommended that future research should focus on formation mechanisms and stabilization strategies. Another critical area of research is pretreatment and modification techniques. Finally, the use of demonstration projects in sectors such as energy, the petrochemical industry, the automotive sector, and construction will help to promote the further development of basalt fiber-based materials.

Further Reading

Liu, H et al. (2022) A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids Polymers 14(12) 2376 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/12/2376

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.