A well-known renewable energy source is solar cell technology. Due to its ability to be printed and mounted to building exteriors or glass windows, organic solar cells, which are a component of the third generation of solar cells, are drawing attention as a key technology for generating solar energy in urban areas.

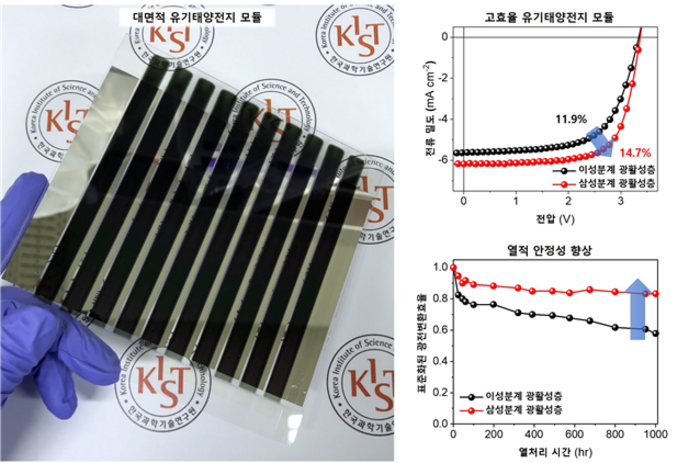

(left) high-efficiency, high-stability, organic solar module incorporating ternary photoactive layers. (right) Performance of the high-efficiency, high-stability, organic solar module incorporating ternary photoactive layers. Image Credit: Korea Institute of Science and Technology (KIST)

(left) high-efficiency, high-stability, organic solar module incorporating ternary photoactive layers. (right) Performance of the high-efficiency, high-stability, organic solar module incorporating ternary photoactive layers. Image Credit: Korea Institute of Science and Technology (KIST)

The photoactive area, which takes in light and turns it into energy, is still a lot less than 0.1 cm2, however. The expansion of the cell area to several m2, where viable energy supply levels are accessible, causes performance and consistency issues that hinder commercialization.

The factors causing performance degradation in large-area organic solar cells were identified by a research team led by Dr. Hae Jung Son of the Advanced Photovoltaics Research Center at the Korea Institute of Science and Technology (KIST).

They also announced the creation of a new polymer additive material for the development of large-area, organic solar cell technology.

The study team concentrated on the solution process, which is a step in the production of organic solar cells, and the compositional form of the photoactive layer in those cells.

As the solvent swiftly evaporates while the substrate rotates at a high speed, the spin coating method, a solution approach mostly utilized in the laboratory research stage, produces a homogenous photoactive layer mixture.

However, the large-area, continuous solution procedure developed for industrial usage produced solar cell performance decline because the solar cell material solution’s solvent evaporation rate was too sluggish. As a result, undesirable agglomeration between the photoactive components developed.

The research team created a polymer additive that interacts with aggregate-prone materials to stop this process. To prevent aggregation in photoactive layers, ternary photoactive layers, including polymer additives, were created.

In addition, enhancements in solar cell efficiency and stability security against light-induced rising temperatures were attained during solar cell operation due to potential nano-level structural management.

A performance improvement of 23.5% over the traditional binary system was made possible due to a 14.7% module efficiency. By sustaining over 84% of original efficiency for 1,000 hours, even in a warm setting of 85 °C, efficiency and stability were both demonstrated.

We have gotten closer to organic solar cell commercialization by proposing the core principle of a solar cell material capable of high-quality, large-area solution processing. commercialization through follow-up research will make eco-friendly self-sufficient energy generation possible that is easily applicable to exterior building walls and automobiles and also utilized as an energy source for mobile and IoT devices.

Dr. Hae Jung Son, Photo-electronic Hybrids Research Center, Korea Institute of Science and Technology

Journal Reference:

Park, S., et al. (2022) Important role of alloyed polymer acceptor for high efficiency and stable large-area organic photovoltaics. Nano Energy. doi:10.1016/j.nanoen.2022.107187.