A paper recently published in the journal Biomaterials reviewed the new advances in three-dimensional bioprinting (3DBP) for regenerative therapy in different organ systems.

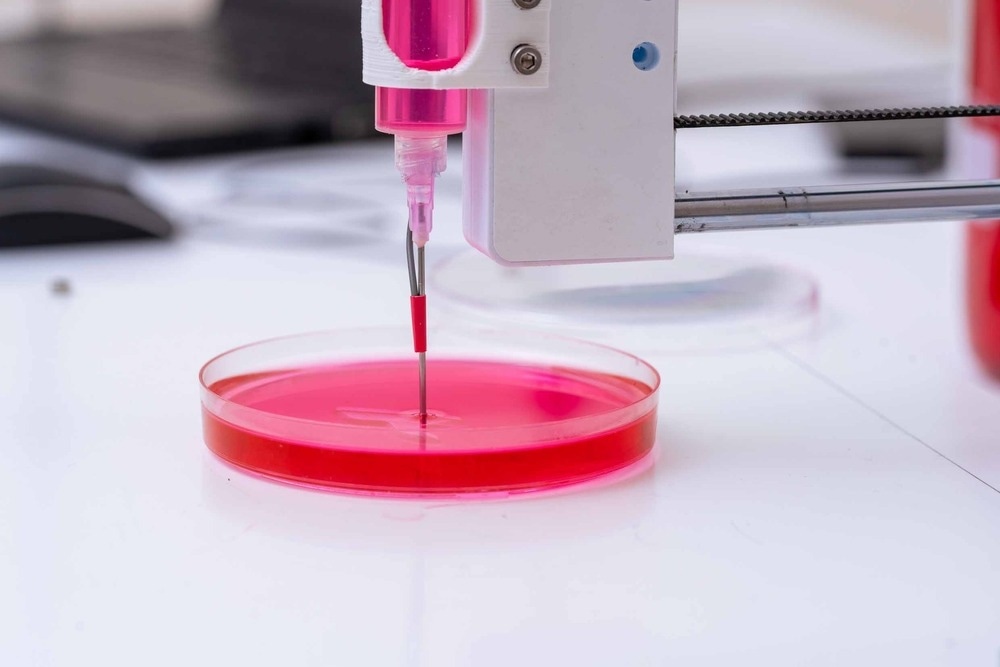

Study: Advances in 3D bioprinting of tissues/organs for regenerative medicine and in-vitro models. Image Credit: luchschenF/Shutterstock.com

Background

Organ/tissue shortage has emerged as a significant challenge in the medical field due to patient immune rejections and donor scarcity. Moreover, mimicking or predicting the human disease condition in the animal models is difficult during preclinical trials owing to the differences in the disease phenotype between animals and humans.

3DBP has gained significant attention as a highly-efficient multidisciplinary technology to fabricate 3D biological tissue with complex composition and architecture. This technology allows precise assembly and deposition of biomaterials with donor/patient’s cells, leading to the successful fabrication of organ/tissue-like structures, preclinical implants, and in vitro models.

In this study, researchers reviewed the 3DBP strategies currently used for regenerative therapy in eight organ systems, including urinary, respiratory, gastrointestinal, exocrine and endocrine, integumentary, skeletal, cardiovascular, and nervous systems. Researchers also focused on the application of 3DBP to fabricate in vitro models. The concept of in situ 3DBP was discussed.

Common Bioprinting Technologies used for 3DBP

Extrusion Bioprinting

In this extensively used low-cost bioprinting method, rotating screw gear or pressurized air is used without or with temperature to extrude a continuous stream of thermoplastic or semisolid material. Different materials can be printed at a high fabrication speed using this technology. However, low cell viability and the need for post-processing are the major drawbacks of extrusion bioprinting.

Inkjet Bioprinting

In this method, liquid drops are ejected on a substrate by acoustic or thermal forces. High fabrication speed, small droplet volume, and interconnected micro-porosity gradient in the fabricated 3D structures are the main advantages of this technique. However, limited printed materials and clogging are the biggest drawbacks of inkjet bioprinting.

Laser-assisted Bioprinting

A laser is used to induce the forward transfer of biomaterials on a solid surface in the laser-assisted bioprinting method. High cell viability and nozzle-free noncontact process are the biggest advantages of laser-assisted bioprinting, while metallic particle contamination and the time-consuming nature of the printing process are the major disadvantages.

Application of 3DBP in Different Organ Systems for Regenerative Therapy

Nervous System

Several studies were performed involving the development of neuronal tissues using the 3DBP method. The pressure extrusion/syringe extrusion (PE/SE) bioprinting technique was used for central nervous tissue (CNS) tissue replacement. The layered porous structure was fabricated using glial cells derived using human induced pluripotent stem cell (iPSC) and a novel bioink based on agarose, alginate, and carboxymethyl chitosan (CMC) formed synaptic networks and displayed a bicuculline-induced enhanced calcium response.

Similarly, stereolithography (SLA) was used to fabricate a 3D scaffold for CNS and the viability of the scaffold was evaluated for regenerative medicine application. Layered linear microchannels were printed using poly(ethylene glycol) diacrylate-gelatin methacrylate (PEGDA-GelMA) and rat E14 neural progenitor cells (NPCs). The 3D scaffold restored the synaptic contacts and significantly improved the functional outcomes. Cyclohexane was used to bond polystyrene fibers to matrix bundle terminals during crosslinking.

Cardiovascular System

Multiphoton excited 3-dimensional printing (MPE-3DP) was employed for the regeneration of myocardial tissue. A layer-by-layer structure was fabricated using GelMA/ sodium 4-[2-(4-morpholino)benzoyl-2-dimethylamino]-butylbenzenesulfonate (MBS) and human hciPSC-derived cardiomyocytes (CMs), endothelial cells (ECs), and smooth muscle cells (SMCs). The crosslinking was performed by photoactivation. The structure promoted electromechanical coupling and improved cell proliferation, vascularity, and cardiac function.

Fused deposition modeling (FDM) and PE/SE bioprinting method were used for complex tissue and organ regeneration. A micro-fluid network heart shape structure was fabricated using polyvinyl alcohol (PVA), agarose, sodium alginate, and platelet-rich plasma and rat H9c2 cells and human umbilical vein endothelial cells (HUVECs). 2% calcium dichloride was used during the crosslinking mechanism. The fabricated structure possessed a valentine heart with hollow mechanical properties and a self-defined height.

SE printing was utilized to fabricate a capillary-like network using collagen type‐1/ xanthan gum and human fibroblasts and ECs for applications in blood vessels. The fabricated network possessed endothelial networks and sprouting between the fibroblast layers.

Skeletal System

Bone, cartilage, and skeletal muscle tissue can be repaired and regenerated using the 3DBP technique. For instance, FDM printing was used to print multifunctional therapeutic scaffolds for the treatment of bone. Filopodial projections were fabricated using polylactic acid (PLA) platform loaded with hyaluronic acid (HA)/ iron oxide nanoparticles (IONS)/ minocycline and human MG-63 and human bone marrow stromal cells (hBMSCs), which improved the osteogenic stimulation of the IONS and HA.

PE/SE method was used to fabricate disks and cuboid-shaped scaffolds using α- tricalcium phosphate (TCP) microgel and human fetal osteoblast (hFOB) and bone marrow-derived mesenchymal stem cell (BM-MSC) for bone repair, multicellular delivery, and disease model. The fabricated structures promoted osteogenesis.

PE/SE bioprinting was also utilized to fabricate complex porous layered cartilage-like structures using alginate/gelatin/HA, rat bone marrow mesenchymal stem cells (BMSCs), and cow cardiac progenitor cells (CPCs) for hyaline cartilage regeneration. The CPCs upregulated gene expression of proteoglycan 4 (PRG4), SRY-box transcription factor 9 (SOX9), and collagen II.

PE/SE printing was also used to fabricate multinucleated, highly-aligned myotube structures using polyurethane (PU), poly(ε-caprolactone) (PCL), and mouse C2C12 myoblasts and NIH/3T3 fibroblasts for in-situ expansion and differentiation of skeletal muscle tendon. The fabricated constructs demonstrated more than 80% cell viability with initial tissue differentiation and development.

Integumentary System

SLA bioprinting technique was used to fabricate bi-layered epidermis-like structure using collagen type I, mouse NIH 3T3 fibroblast cells, and human keratinocyte cells for tissue model and engineering. The fabricated constructs effectively imitated the tissue functions.

Similarly, PE was employed to fabricate microporous structures using human amniotic mesenchymal stem cells (AFSCs) and heparin-HA-PEGDA for wound healing. The construct improved the wound closure and reepithelialization, increased extracellular matrix synthesis and vascularization, and prolonged the cell paracrine activity.

PE technique was utilized to prepare a multilayered cornea-like structure using human keratocytes and methacrylated collagen (ColMA)-alginate. The cell viability of the keratocytes decreased from 90% to 83% after printing.

Gastrointestinal, Respiratory, and Urinary Systems

PE/SE bioprinting was utilized to bioprint multilayered liver-like structures using GeIMA and human HepG2/C3A for liver tissue engineering. Similarly, hepatocytes were also bioprinted to fabricate multiple organ precursors with branching vasculature. A small intestine model with improved intestinal function and high cell proliferation was fabricated using caco-2 cell-loaded polyethylene vinyl acetate (PEVA) scaffold.

Spheroids of mesenchymal stem cells (MSCs) and chondrocytes and lung endothelial cells were utilized to fabricate scaffold-free tracheal transplant. After implantation in the rat model, the matured spheroids displayed excellent vasculogenesis, chondrogenesis, and mechanical strength. FDM technique was used to fabricate a glomerular structure for kidneys using human iPSCs and hydrogel and a hollow porous network using poly(lactic-co-glycolic acid (PLGA)/PCL/tumor-associated endothelial cells (TECs) for the urethra.

In-situ Bioprinting

In in-situ bioprinting, the tissue is directly printed on the specific defect or wound site in the body for regenerative and reparative therapy. This method provides a well-defined structure and reduces the gap between host-implant interfaces. In-situ bioprinting is better than in vitro bioprinting techniques as the patient’s body, as a natural bioreactor, provides a natural microenvironment.

Several studies have evaluated this technique for tissue regeneration. For instance, PE/SE method was used for skin tissue regeneration in pigs and mice using fibrin/collagen/HA and human fibroblast cells. Skin-laden sheets of consistent composition, thickness, and width were formed upon rapid crosslinking of biomaterial. PE/SE technique was also used for neural tissue regeneration in mice using agarose/CMC/alginate and human iPSCs.

Bioprinting of In Vitro Models

In vitro models provide significant assistance in understanding the mechanism of therapeutics and disease pathophysiology. Recently, in vitro models of human tissues and organs were engineered using 3DBP technology for safety assessment and drug testing.

Conclusion and Future Outlook

In the 3DBP of organs and tissues, biomaterials play a crucial role in maintaining cellular viability, providing support, and long-term acceptance. Specifically, bioinks must possess unique properties, such as cell growth promotion and structural stability, that can be optimized for clinical use. Additionally, bioinks must be compatible with printers for high-precision rapid prototyping.

Bioinks fulfilling all of these requirements are yet to be identified. Moreover, managing the time during the bioprinting of the constructs is another major challenge, as the time required to fabricate them is often more than the survival time of cells. A bioreactor platform that supports organoid growth and provides time for tissue remodeling can be used to overcome this challenge. Ethical challenges and issues are also a hurdle since fabricating internal tissues/organs can lead to liability and biosafety concerns.

In the future, 3DBP can provide novel solutions to engineer organs/tissues and revolutionize modern healthcare and medicine if these challenges can be addressed.

More from AZoM: Building Durable and Sustainable Futures with Graphene@Manchester

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Jain, P., Kathuria, H., Dubey, N. Advances in 3D bioprinting of tissues/organs for regenerative medicine and in-vitro models. Biomaterials 2022. https://www.sciencedirect.com/science/article/abs/pii/S0142961222002794?via%3Dihub