By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 14 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 14 2022In an article recently published in the journal Additive Manufacturing, researchers discussed the evaluation of the rheology and printability of complexly formulated, nutrient-dense food printed in three dimensions (3D).

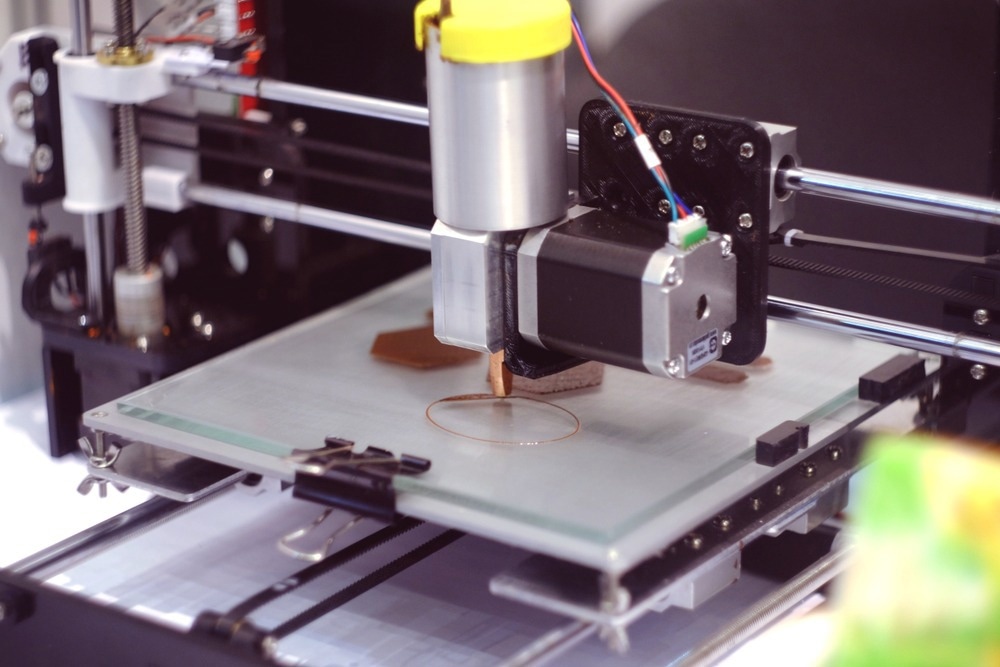

Study: Evaluation of rheology and printability of 3D printing nutritious food with complex formulations. Image Credit: Maksym Kaharlyk/Shutterstock.com

Background

The potential to create and develop food for target populations with specific nutritional needs has received a lot of attention. One of the main reasons for the quick development of 3D food printing is the prospect of individualized nutrition in the near future.

For personalized nutrition to deliver a nutritious diet based on appropriate, balanced nutritional guidelines, complex food formulations comprising numerous elements such as fruits, dairy, vegetables, and other animal products are required. A complicated multi-component custom food composition has proven to be difficult to print due to the challenges of the extrusion-based printing method, despite the fact that nutritive formulations have been reported.

In addition to processing parameters, research on rheological characteristics and printability factors may reveal important information about how the material will behave throughout the printing process. Although rheological qualities used in 3D printing have been researched, there is always room for improvement in the quantitative relationship between these factors and printability. Since the conception of the food printing process, hydrocolloids have been used in this area because they prevent the powder particles from expanding, which affects the rheological qualities. The versatility, high reliability, low cost, and ease of handling of these hydrocolloids over others, however, have not been thoroughly examined in 3D food printing applications.

About the Study

In this study, the authors described up to nine substances which included byproducts like orange peel and sustainable proteins, which were contained in the nutrient formulations (insect flour). The objective of this study was to assess and connect the printability and rheological characteristics of complex food formulations that were nutrient-dense. The pregelatinized corn starch concentration of 4–10% (w/w) and printing temperature of 27–47 °C were adjusted. The examined food inks were subjected to rheological characterization using an amplitude sweep, a shear-viscosity test, a time-dependent shear test, a shear-recovery test, a temperature sweep, and a temperature ramp in oscillatory mode. Through a digital image analysis of the geometrical characteristics of the printed structures, printability was assessed.

The team used 9 substances in the nutrient formulations that were provided in this study for the first time. These included innovative, functional dietary, unconventional ingredients, which included sustainable sources such as insect flour and byproducts such as orange peel. Additionally, preliminary mathematical connections between rheology and printability were shown for the novel formulations, and these correlations were used in the development of sophisticated food printing systems.

The researchers assessed and compared the printability and rheological characteristics of complex food compositions that were nutrient-dense. This was accomplished by varying the printing temperature and the concentration of one of the ingredients.

Observations

At nozzle temperatures of 27, 37, and 47 °C, respectively, the stress at collapse values for F1-4% were 761.6, 729.8, and 620.3 Pa. The greatest values, on the other hand, were found in F4-10%, which reached up to 1835.5 Pa at 27 °C. Even under the stress of numerous layers and notably at 27 °C, the remaining formulations showed a higher level of printability with a smaller printing percentage error compared to F1-4%. Extruded filaments from formulations F2-6%, F3-8%, and F4-10% possessed smooth, uniform shapes that allowed for the manufacture of almost square-shaped 2D structures, as opposed to the round forms or unfinished 2D structures seen in F1-4%.

The yield stress and the storage modulus increased as the pregelatinized starch concentration increased from 4 to 10%. High rheological parameter values, however, were not translated into better printability. The printability assessment revealed that formulations containing 6% and 8% pregelatinized starch were better suited for printing than the formulation containing 10%. The results demonstrated that when printing complicated formulas for the creation of customized food items, both rheology and printability analyses must be carried out.

The results showed that higher concentrations were not always better for printing. In the examination of the printability of samples where shape deformation and inconsistency were examined, F4-10% proved to be less successful than F3-8%. The deformation and flow states of formulations under various environmental variables were embodied by rheology, which was directly related to the development of 3D structural elements.

Additionally, it was established that although rheological factors were important for determining the properties of the material, some of them could not accurately predict how the material would behave after printing. High static yield stress and improved thixotropy in the extrusion and stacking system were required for food materials in order to properly characterize and correlate their rheological properties with printability, which was the main challenge in the development of a printed structure for these materials.

Conclusions

In conclusion, this study presented four nutrient-dense formulations combining up to nine unique and unconventional functional food ingredients. In order to potentially develop sophisticated food printing systems, preliminary mathematical correlations between the rheology and printability of such formulations were discovered. Pregelatinized starch improved the shear-thinning behavior and thermal stability of formulations by raising G', yield stress, and viscosity values while lowering δ. This improved the formulations' printability, shape retention, and stability performance, which was helpful for both printing processes.

It was possible to efficiently discover and generalize critical factors for new customized nutrient formulations by using the proposed characterization and correlation. The authors mentioned that future studies on 3D food printing may be guided by the knowledge gained from this study in order to improve the behavior of the formulations during printing. They also stated that the discoveries made could serve as a design template for the creation of unique individualized formulations that would make better choices for specialized food 3D printing items.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Maldonado-Rosas, R., Tejada- Ortigoza, V., Cuan-Urquizo, E., et al. Evaluation of rheology and printability of 3D printing nutritious food with complex formulations. Additive Manufacturing 103030 (2022). https://www.sciencedirect.com/science/article/abs/pii/S2214860422004225