The Southwest Research Institute and the University of Texas in San Antonio are working together to create a hybrid metal-carbon microstructure that encompasses both chemical and physical hydrogen storage processes to enhance storage materials for hydrogen fuels.

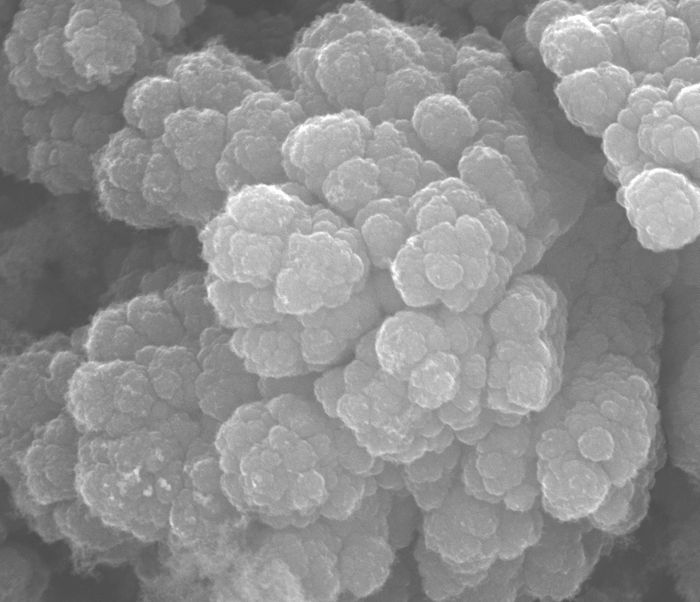

SwRI and UTSA will create high surface area carbon (HSAC) microstructure particles that can chemically absorb hydrogen, storing it for safe and cost-effective transport. The project is supported by the Connect program, which offers grant opportunities to enhance greater scientific collaboration between the two institutions. Image Credit: Southwest Research Institute

SwRI and UTSA will create high surface area carbon (HSAC) microstructure particles that can chemically absorb hydrogen, storing it for safe and cost-effective transport. The project is supported by the Connect program, which offers grant opportunities to enhance greater scientific collaboration between the two institutions. Image Credit: Southwest Research Institute

Dr. Kathryn Mayer, associate professor of physics and astronomy at UTSA, Dr. Josh Mangum, and Dr. Fang Xu, assistant professor of chemistry at UTSA, will lead the study, which is funded by a $125,000 grant from the Connecting through Research Partnerships (Connect) Program.

Since hydrogen fuel does not emit any carbon byproducts, it is a desirable alternative to fossil fuels. Hydrogen is being examined as a potential fuel for cars and power plants, and possibly as an alternative to gas in households as part of numerous multidisciplinary projects that SwRI is leading.

While hydrogen energy is very promising, several hurdles must be overcome. Some of the chief challenges are transportation and storage.

Dr. Josh Mangum, Assistant Professor, Chemistry, University of Texas in San Antonio

It is expensive to compress and liquefy hydrogen gas for storage and transportation in cryogenic and high-pressure fuel tanks, which is how hydrogen is currently transported and stored. Transporting these tanks also poses significant risks as hydrogen is highly combustible.

SwRI and UTSA will develop high surface area carbon (HiSAC) microstructure particles to overcome these difficulties and enable the cost- and safety-effective transportation of hydrogen.

Instead of a highly pressurized tank, we plan to store hydrogen in a low-cost powder material. The hydrogen will be chemically and physically absorbed and desorbed. One of our project goals is evaluating how much hydrogen can be stored in the powder since this will dictate the overall storage cost.

Dr. Josh Mangum, Assistant Professor, Chemistry, University of Texas in San Antonio

The High Power Impulse Plasma Source (HiPIPS) technology, created by SwRI, efficiently produces coatings utilizing high-density, high-flux plasmas at low temperatures and atmospheric conditions. The scientists will use this technology to build the HiSAC microstructures. HiPIPS technology from SwRI was named one of the top 100 breakthroughs of 2017 by R&D Magazine.

The analytical characterization of the microparticle structures will be carried out by UTSA. Using cutting-edge equipment in the Kleberg Advanced Microscopy Center, Mayer’s research group will thoroughly characterize the materials’ structural properties. Xu’s team will modify HiSAC by adding magnesium, and they will use a special apparatus to measure how much hydrogen can be stored in the materials.

“Previous research has demonstrated HSAC microstructures at high temperatures and low pressures, but HiPIPS allows us to form these materials at room temperature in a simple, scalable process. This process uses less energy than it takes to power an incandescent light bulb,” Mangum said.

The Executive Office of SwRI and the Office of the Vice President for Research, Economic Development, and Knowledge Enterprise at UTSA sponsor the Connect initiative, which provides grant opportunities to enable better research collaboration between the two organizations.