Perovskite films, which combine organic and inorganic materials, have been under review by scientists since 2009 as a potential material for solar panel manufacturing. In contrast to silicon wafers, perovskites are extremely thin films with a particular crystal structure that is efficient, lightweight, and inexpensive.

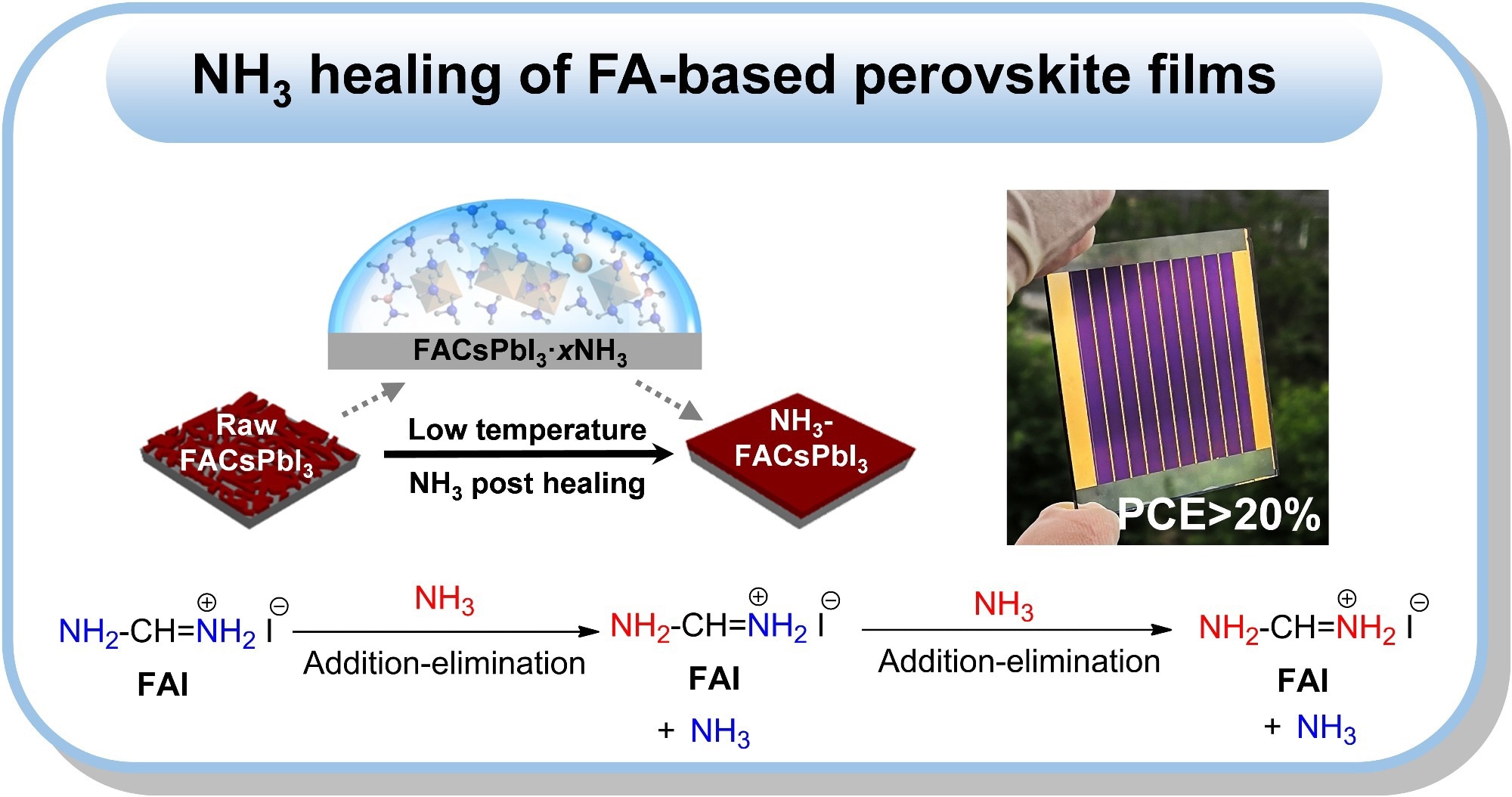

Ammonia healing of formamidinium-based perovskite films. Image Credit: Zhipeng Li

Ammonia healing of formamidinium-based perovskite films. Image Credit: Zhipeng Li

The commercialization of perovskite solar cells has been hampered by present constraints, such as how to make uniform perovskite films on a wide scale.

Scientists from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), the Chinese Academy of Sciences (CAS) have recently described a new method of processing formamidinium-based perovskite film. This method uses ammonia treatment to get rid of pore structures that were created during the processing, which alleviates some of the limitations.

On July 29, the report was released in Nature Communications.

The highest power conversion efficiency of perovskite solar cells is comparable to that of widely commercialized silicon-based solar cells. However, how to achieve large-area preparation of highly uniform perovskite film remains a challenge.

Shuping Pang, Study Corresponding Author and Professor, Qingdao Institute of Bioenergy and Bioprocess Technology

Despite substantial research into the techniques and solvents used to manufacture perovskite films, perovskite films still need extra components or processing processes to function. Comapred to the more effective formamidinium-based perovskite, the exceedingly potential methylamine gas healing approach is only appropriate for methylammonium-based perovskite.

The scientists initially looked into the underlying processes that were causing problems with the gas healing of the formamidinium-based perovskite films.

“We have shown that the degradation of formamidinium-containing perovskites is caused by a reaction between the formamidinium cation and aliphatic amines, producing ammonia,” said Xiao Wang, the second author of the study.

The scientists treated formamidinium-based perovskite films using ammonia rather than methylamine gas to prevent the development of adverse reactions.

The temperature is decreased using this approach so that the perovskite film can collect enough ammonia to change into a flowable intermediate state. The raw perovskite film’s flaws and hole structures can be repaired in this flowable form.

The scientists were able to create a perovskite film with greater power conversion efficiency and easy large-scale replication using this method.

The perovskite solar cell based on ammonia post healing achieves a power conversion efficiency of 23.21% with excellent reproducibility.

Zhipeng Li, Study First Author, Qingdao Institute of Bioenergy and Bioprocess Technology

The adsorption and desorption rate must be tightly controlled at low temperatures and promptly for the ammonia gas healing operation. The ease with which it may be incorporated into already existing, well-established commercial technologies is yet another advantage of adopting ammonia gas post-healing technology.

In the future, scientists are considering how to effectively design the machinery required for making perovskite films using this technique, which is essential for commercializing perovskite solar cells.

Journal Reference:

Li, Z., et al. (2022) Ammonia for post-healing of formamidinium-based Perovskite films. Nature Communications. doi.org/10.1038/s41467-022-32047-z.