A new paper in the journal Sustainability has explored the recycling of 3D-printed nylon composites with the aim of improving the sustainability of the additive manufacturing industry. The research has been conducted by scientists from UAE University in the United Arab Emirates.

Study: Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes. Image Credit: Joaquin Corbalan P/Shutterstock.com

The Scale of Plastic and Composite Polymer Waste

According to some reports, by 2050 there could be more plastic waste in the ocean than fish. The critical issue of the vast amounts of waste polymers and composite materials entering the natural environment has crystallized action in industry and government to limit the ecological damage it causes.

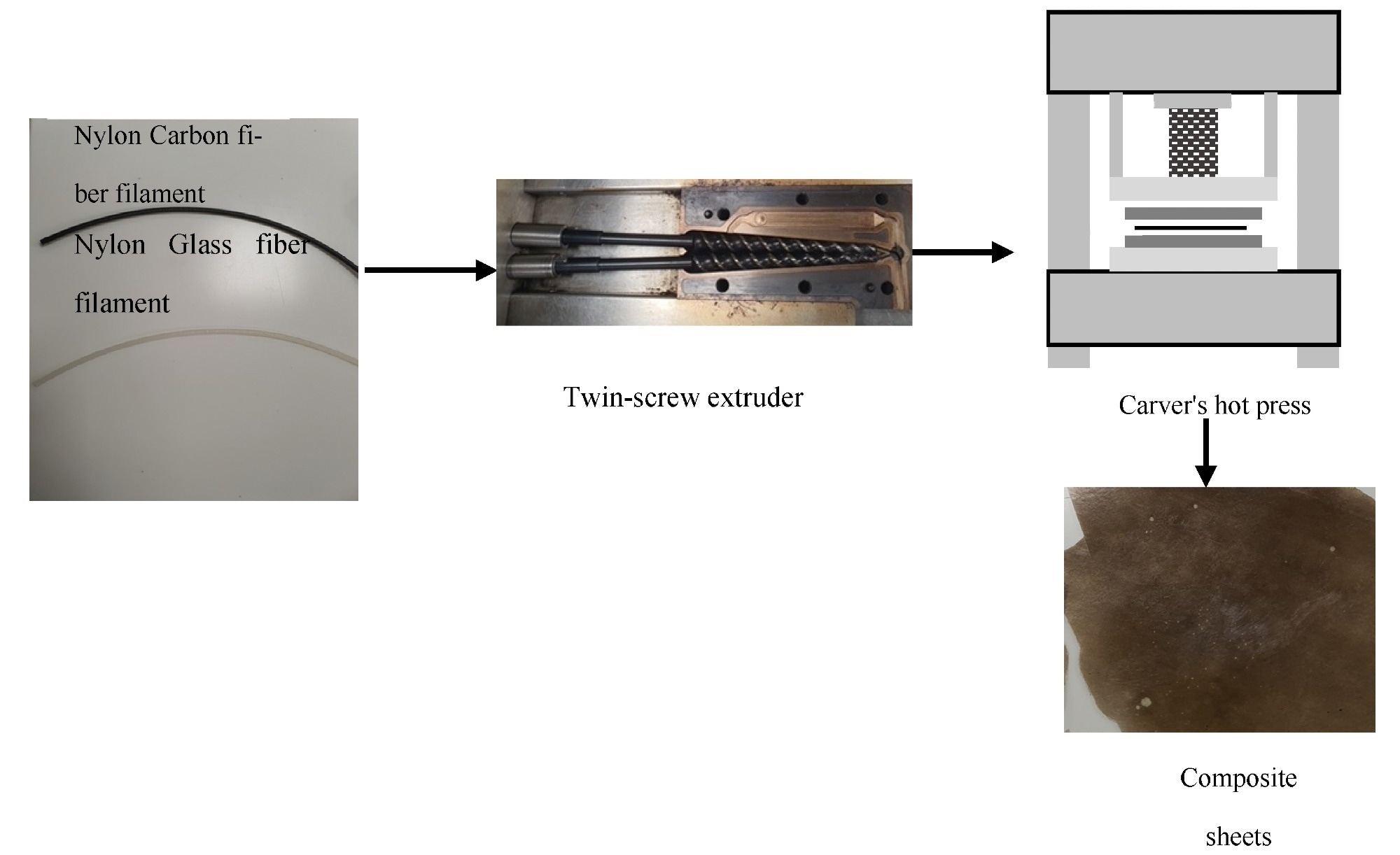

Schematic diagram of the material preparation process. Image Credit: Al-Mazrouei, N et al., Sustainability

The National Geographic Society has estimated that there are currently 5.25 trillion pieces of plastic debris in the ocean, ranging in size from complete products to microplastic fragments. Microplastics are a particular problem as they can be consumed by marine organisms and enter the food chain, causing damage to human and animal health. Plastic waste is found from the surface to the depths of the ocean.

3D Printing and Waste Materials

The field of additive manufacturing has provided innovative solutions for numerous industries due to the design freedom and cost effectiveness of 3D printing technologies. One of the hallmarks of 3D printing is the reduction of waste materials compared to traditional manufacturing techniques. Products are constructed layer by layer from raw materials.

Whilst waste is significantly reduced during 3D printing, there are still critical issues with waste in the industry that impacts its overall sustainability. Products, especially composite filaments which are produced by commercial fused deposition modeling techniques, are an additional source of plastic waste that complicates environmental remediation efforts.

Waste can be generated during additive manufacturing processes due to issues such as poor filament quality, hardware failures, slicing errors, and adhesion issues in the print bed. Recycling waste materials can be a complicated process, for instance in the case of composites incorporating glass fibers and carbon fibers due to toxic heavy metals produced during manufacturing.

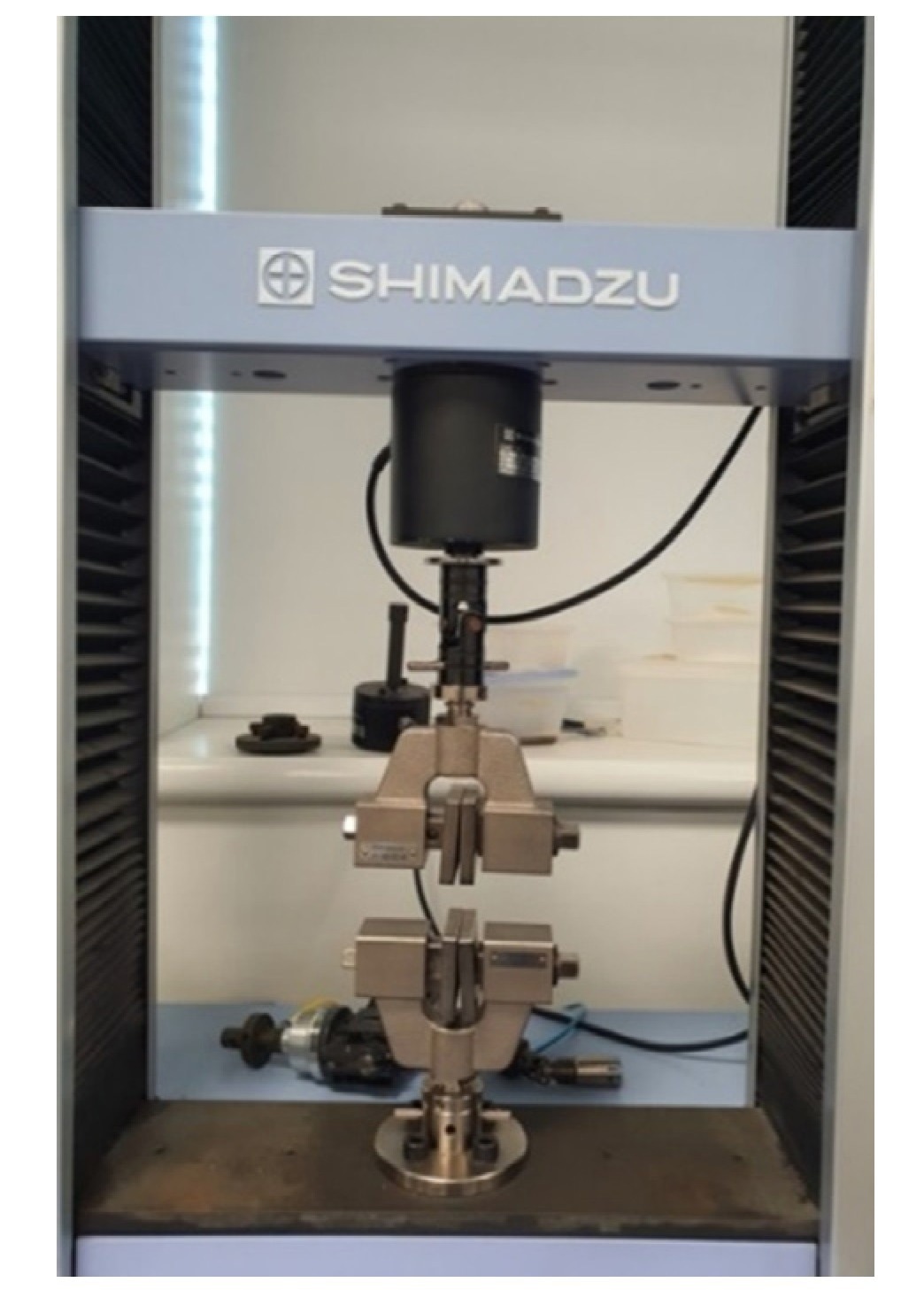

Tensile testing machine. Image Credit: Al-Mazrouei, N et al., Sustainability

Recent studies have focused on combining different synthetic fibers and polymers to enhance the properties of composites manufactured by 3D printing methods, such as carbon fibers, glass fibers, and nylon fibers. Specific material challenges are associated with each reinforcing fiber, with different effects on final product properties observed by researchers.

Challenges with dimensional quality control and the consistency of material properties cause issues with the recycling of 3D-printed polymer composite wastes. However, recycling some waste materials is possible but limited. In the case of materials incorporating carbon fiber, 30% of waste can be recycled. Prototyping parts produced using FDM techniques can be recycled and reused.

The Research

Recognizing the inherent difficulties involved with manufacturing 3D-printed polymer composites and the recyclability and reusability of waste materials produced during processing, the authors have produced recycled blended composite polymers.

Researchers blended 3D-printed composite wastes, carbon fiber-reinforced nylon, and glass fiber-reinforced nylon. This approach produced recycled composite sheets of CFGF/nylon materials. 3D printing waste filaments were used, providing a solution for improving the circularity of these materials. Composites were produced using different blending compositions.

To produce the composite sheets, the authors used a process that combines compression molding and a twin extruder machine. The thermal and mechanical properties of the produced composite sheets were evaluated. Mechanical properties such as the composite materials’ elasticity modulus, toughness, tensile strength, and ductility were assessed. FTIR and thermogravimetric analysis was used in the study.

Study Results

The paper has demonstrated the suitability of recycled 3D printing waste materials for manufacturing new functional products. Analysis of composite sheets incorporating different blends of carbon-fiber, glass-fiber, and nylon-fiber reinforced materials revealed several important properties of each material.

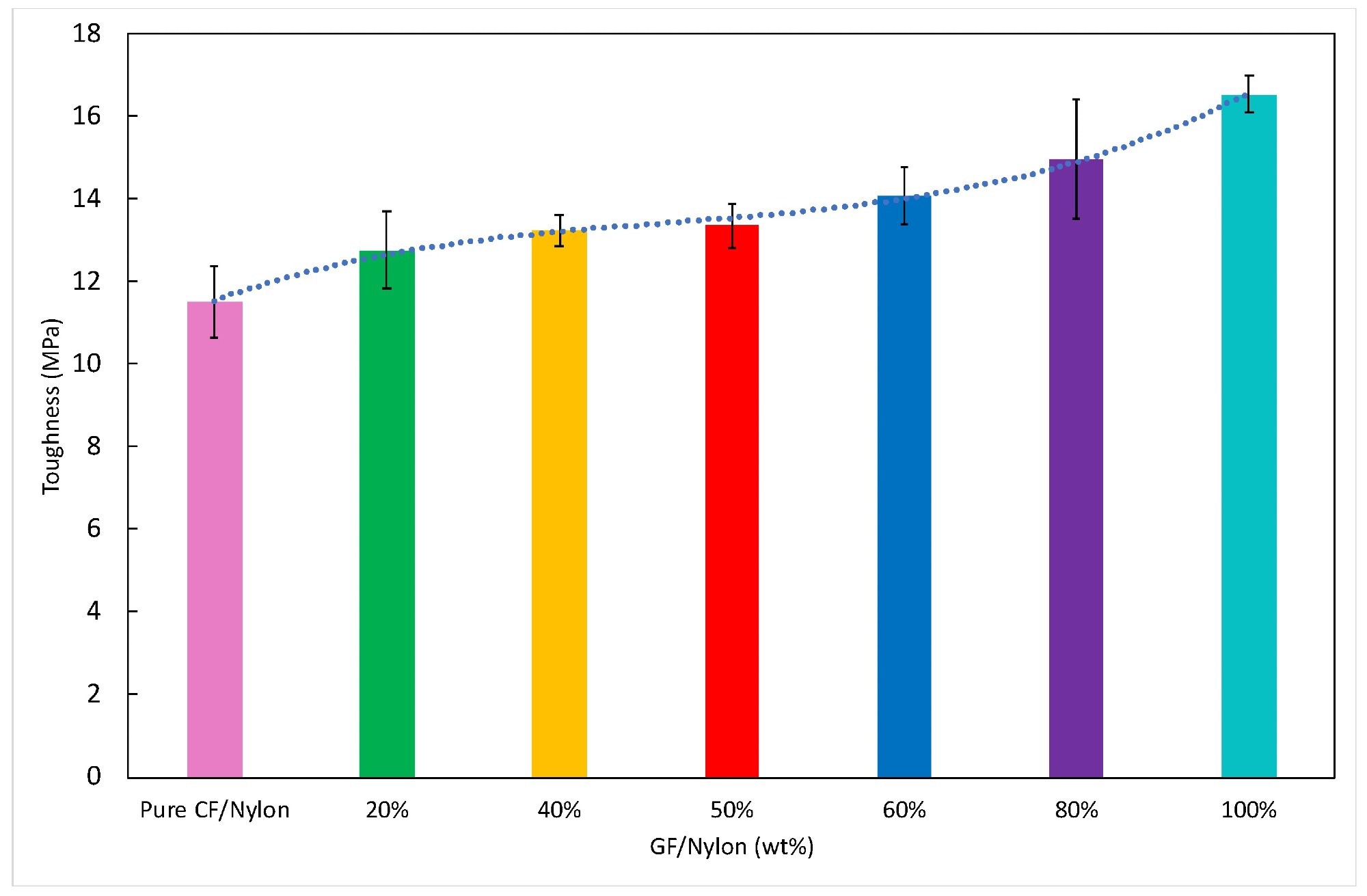

Comparison of the toughness of the composites. Image Credit: Al-Mazrouei, N et al., Sustainability

The highest toughness and ductility were observed in pure glass fiber/nylon-reinforced polymer composites. Whilst this was the highest observed result, the authors also revealed that adding 20% wt of glass fiber/nylon to carbon fiber/nylon composites increased their tensile strength. An increase in glass fiber/nylon from 50-60 wt% improved elastic modulus, but at 80% wt it decreased.

Thermal analysis revealed that pure carbon fiber/nylon composites possess an elevated degradation temperature compared to pure glass fiber/nylon composites. Furthermore, incorporating glass fiber/nylon decreases the composite’s degradation temperature.

In Summary

Recyclability of 3D printing waste materials is a key research area in the industry currently. Being able to recycle and reuse polymers and composite materials will improve the sustainability and circularity of additive manufacturing and, consequently, the numerous industries that are increasingly employing 3D printing methods.

The team behind the paper has stated that the results of their study could be used in research into recycling numerous 3D printed filament waste, providing several innovative opportunities for future research.

Further Reading

Al-Mazrouei, N et al. (2022) Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes Sustainability 14(17) 10458 [online] mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/17/10458

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.