Writing in the journal Polymers, a team of researchers from Rocket Force University of Engineering and Qingdao University of Science and Technology have published a paper investigating the use of artificial bee colony algorithms to predict rubber product life cycles.

Study: Natural Aging Life Prediction of Rubber Products Using Artificial Bee Colony Algorithm to Identify Acceleration Factor. Image Credit: Imabulary/Shutterstock.com

Evaluating the Lifetime of Rubber Products

Rubber is a key engineering material used in a wide variety of commercial products. Common applications of natural and synthetic rubber include tires, insulation materials, air springs, catheters, medical tubes, and a number of sealing agent. Superior physical properties and performance make rubber an attractive material for numerous industries from transportation to manufacturing and medical science.

Rubber products, like all materials, have a serviceable lifespan. Catastrophic failures and safety issues can occur if faults and damage are not detected in time, meaning that accurate prediction methods are crucial for ensuring the safe operation of products containing natural or synthetic rubber.

Predicting the useful and safe lifetime of rubber products is of paramount concern to engineers and researchers working in this field of materials science. To provide these predictions, accelerated aging tests and associated data-processing techniques are employed by researchers, with studies increasingly focusing on developing improved tests.

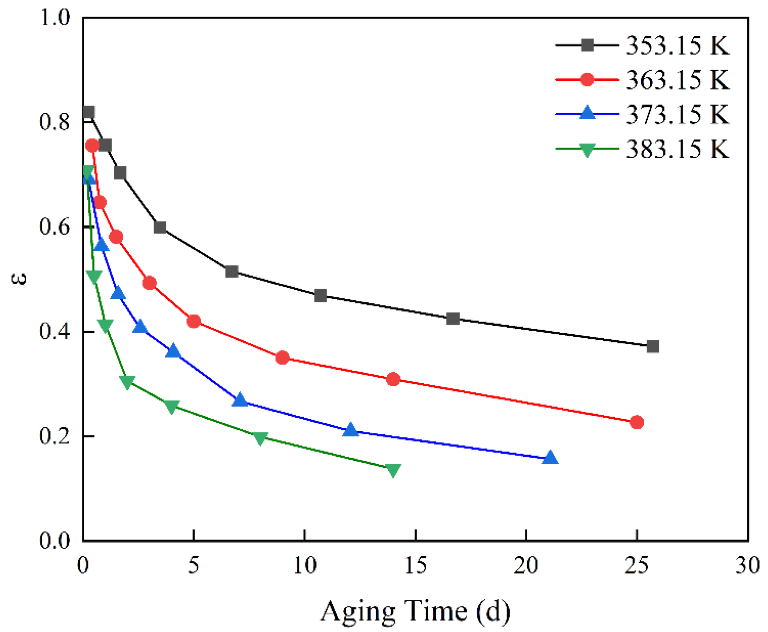

Accelerated aging tests are preferable to natural aging tests, as the natural lifespan of different rubber products, depending on the material used, can range from three to twenty-five years. Natural aging tests are costly and time-consuming, making them unsuitable for product design.

Changes in compression set retention with time. Image Credit: Guo, X et al., Polymers

Using Computer Modeling to Predict Rubber Product Lifetimes

Accelerated aging tests are based on the principle of time-temperature equivalence, which states that rubber aging rates accelerate at higher temperatures, reducing the time to failure. By extrapolating temperature-dependent acceleration factors to the real-world use of products, the time until failure can be predicted. To enhance the accuracy of these predictions, methods based on computer modelling are increasingly being employed.

Multiple fittings can lead to error supposition problems, which hinders accurate acceleration factor determination. Whilst research into intelligent algorithms has provided improvements in prediction, there is still room for improvement. Conventional data processing methods suffer from low efficiency due to error superposition caused by the need to fit data multiple times at each temperature.

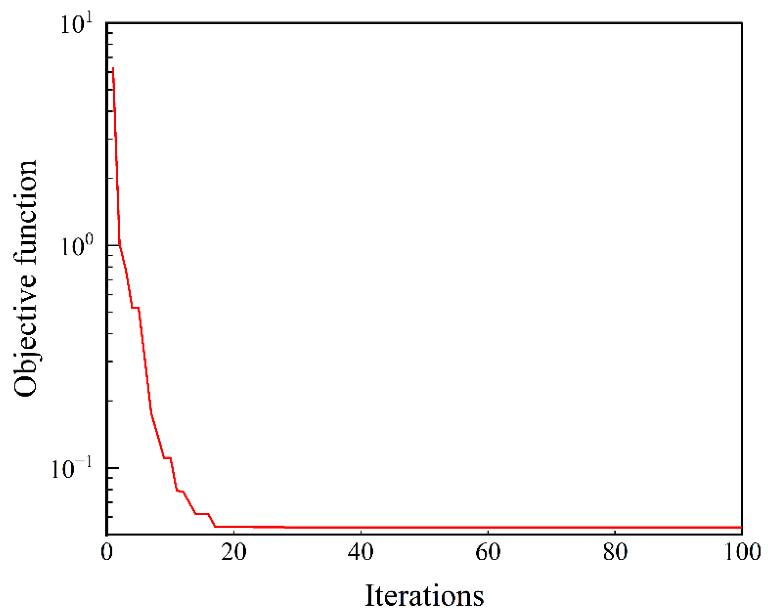

Convergence of the objective function with the number of iterations of the algorithm. Image Credit: Guo, X et al., Polymers

The Study

The new paper in Polymers has investigated how to improve lifetime predictions for rubber products. A novel approach is presented by the authors using an algorithm based on bee colonies. The innovative architecture of the algorithm helps to determine the optimal value of acceleration factors in accelerated aging tests.

The algorithm encodes acceleration factors as candidate solutions. This improves both accuracy and speed, significantly enhancing the efficiency of data processing. An improved Arrhenius equation is achieved with this method which considers non-Arrhenius phenomena in aging processes.

Power exponent factors were incorporated into the algorithm, which accounts for the phenomena of non-constant activation energy during aging. This overcomes issues with error superposition during accelerated aging tests, improving the equation.

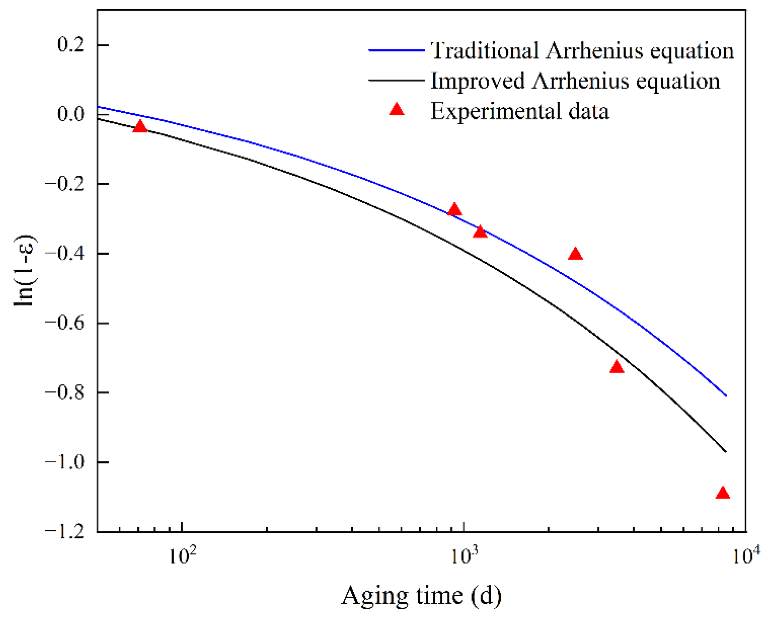

The accuracy of the improved equation was verified by the authors by comparing it to methods utilizing traditional equations. By employing this novel algorithm-based method, the aging lifetime of a commercial rubber product was accurately predicted in its natural environment.

Study Findings

The study revealed the high accuracy of the novel artificial bee swarm algorithm for predicting lifetime until failure in ethylene-propylene rubber at 25oC. Results indicated that the algorithm possesses higher prediction accuracy over longer aging processes, whilst conventional equations perform better for predicting aging under six years.

The acceleration factor at each aging temperature to reference temperature was translated using the acceleration factor obtained by the intelligent algorithm presented in the research. It is a highly accurate alternative to current prediction models.

Comparison of traditional and improved Arrhenius equations in fitting experimental data. Image Credit: Guo, X et al., Polymers

In Summary

The paper has presented a novel algorithm-based approach for accurately determining the lifetime of a commercial rubber product in its natural environment. The advantage of using the artificial bee swarm algorithm is in its ability to overcome data error superposition issues at different acceleration temperatures in aging tests.

Accurately predicting the time to failure for commercial rubber products is a key engineering question which relies on state-of-the-art approaches like the one introduced in the new study. Whilst the authors have not aimed to design an algorithm that eclipses other approaches in its performance, they have aimed to demonstrate the efficacy of their algorithm as an alternative approach.

The beauty of this novel swarm algorithm is in the simplification of data acquisition and processing and the avoidance of error accumulation, which improves its accuracy and reliability. The algorithm can be considered for use in predicting rubber product lifetime.

Further Reading

Guo, X et al. (2022) Natural Aging Life Prediction of Rubber Products Using Artificial Bee Colony Algorithm to Identify Acceleration Factor Polymers 14(17) 3439 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/17/3439.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.