A new paper published in Carbohydrate Polymers explores the development of novel chitosan hydrogels with favorable strength properties. Scientists from Tiangong University’s School of Chemistry in China have conducted the research.

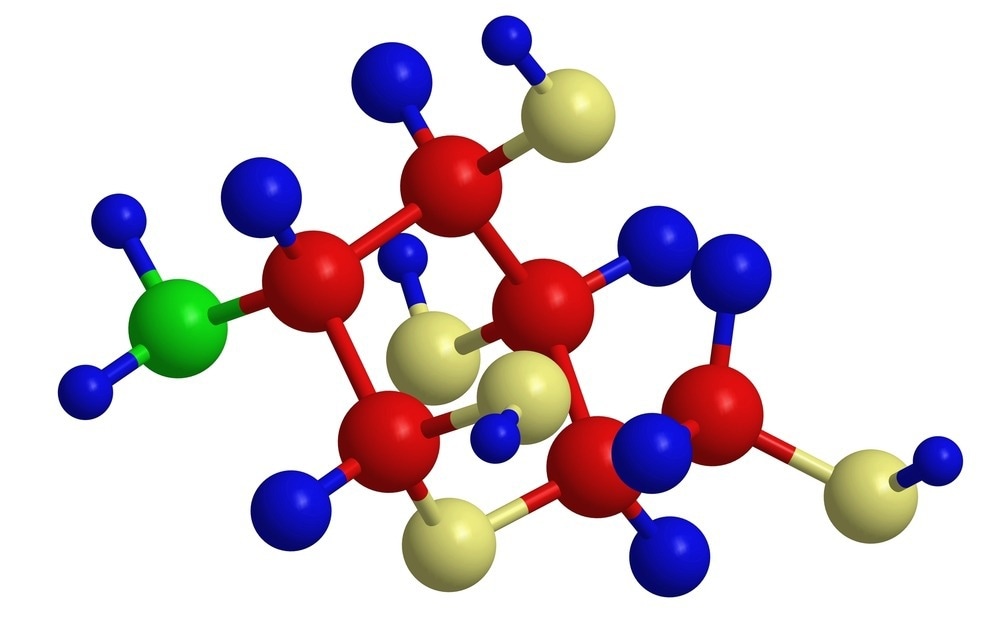

Study: High strength chitosan hydrogels prepared from NaOH/urea aqueous solutions: The role of thermal gelling. Image Credit: Raimundo79/Shutterstock.com

Chitosan Hydrogels

Chitosan is a natural polysaccharide found primarily in the shells of crustaceans. This organic material possesses many advantageous properties for industry including biodegradability, biocompatibility, non-toxicity, non-antigenicity, hemostatic capability, and antimicrobial activity. This has made chitosan especially attractive for the biomedical industry.

In the biomedical industry, chitosan is engineered into hydrogels used for innovative applications such as drug delivery, wound dressings, and tissue engineering. Low molecular weight or macromolecular crosslinkers can be used to synthesize chemical chitosan hydrogels. Physical hydrogels can be prepared by exploiting non-covalent interactions, such as electrostatic or hydrophobic interactions, which form physical networks.

Physical Chitosan Hydrogels

Physical hydrogels composed entirely of chitosan have increased in attractiveness in recent years as the original chemical structure does not need to be modified. Additionally, there is no need for crosslinking agents or the addition of other polymers. Non-covalent interactions and molecular entanglements provide chitosan chain crosslinking abilities during preparation.

In these hydrogels, the physiochemical and biological properties of chitosan can be preserved, such as its biodegradability. Traditionally, dilute mineral acids have been used to dissolve chitosan to prepare the hydrogels, followed by exposure to bases such as ammonia gas which causes the solution to coagulate.

Preparing physical pure chitosan hydrogels using conventional methods is challenging, however, as the final product suffers from poor mechanical properties, which hinder their commercial viability. Research has demonstrated the beneficial use of non-acidic solvents such as alkali solutions like urea and coagulants such as water-miscible organic solvents and H2SO4/ethanol hot aqueous solutions.

Using these approaches produces physical pure chitosan hydrogels with enhanced properties compared to conventional acid solvent-based preparation methods. However, there is a lack of research knowledge on why this alkali solvent approach produces mechanically strong chitosan hydrogels.

The Study

Based on the results of previous studies by the authors wherein they dissolved chitosan in an aqueous NaOH/urea solution, they have investigated the role of gelation processes in producing physical pure chitosan hydrogels. Previous work using their novel two-step process has produced hydrogels with high mechanical strength.

The two-step process presented in the author’s body of research involves a heat treatment step that enhances physical gelling followed by a water-soaking step that displaces the solvent. By reducing the need for harsh chemicals during the displacement step, this process can be considered to be a greener chemical synthesis method than conventional hydrogel preparation strategies.

The paper notes that another study has used a similar method to produce physical hydrogels from pure chitosan. In this study, a LiOH/urea solution was used to prepare the hydrogels. It was discovered that hydrogels prepared using the two-step method possess different microstructures from hydrogels produced with acidic solvents. However, the reason for this was not properly elucidated.

It has been hypothesized in the paper that the gelation process is a dominant factor that governs the differences between hydrogel microstructures. Understanding how this works could help to control the hydrogel microstructure by tuning parameters during synthesis.

Microstructural and mechanical property categorization of prepared hydrogels has been performed in the paper. In particular, the authors have examined the effects of treatment parameters on the hydrogel microstructures and mechanical properties. Based on their observations, the authors have proposed a mechanism that emphasizes thermal gelling which explains the hydrogel’s enhanced properties.

Study Findings

Mechanical properties were examined using compressive and tensile tests, and SEM and XRD were employed to provide microstructural characterization. The improved mechanical strength in chitosan hydrogels synthesized via the NaOH/urea method can be explained by the material’s more compact and homogenous microstructure compared to hydrogels prepared via acidic solvent methods and a high degree of crystallinity.

The authors have proposed that thermal gelling during heat treatment forms a primary polymeric network. Chitosan chains are then deposited on this template during the solvent displacement step, forming a compact and strong, compact, and homogenous hydrogel structure. Crystal domains in the primary structure also facilitate chitosan chain crystallization during solvent displacement.

Higher and more prolonged heat treatment produces hydrogels with stronger mechanical strength, with water-soaking temperature having a negligible influence. It was also discovered by the authors that this process can be simplified further by directly soaking the alkaline chitosan solution in hot water.

By revealing the role of the gelation process in physical pure chitosan hydrogel formation and its effect on the material’s mechanical strength, the authors have helped to plug a current research gap. The chitosan hydrogels prepared in this research have potential applications in fields such as tissue engineering and advanced wound dressings.

More from AZoM: A Closer Look at Semiconductor Test Equipment

Further Reading

Lu, Z et al. (2022) High strength chitosan hydrogels prepared from NaOH/urea aqueous solutions: The role of thermal gelling Carbohydrate Polymers 120054 [online, pre-proof] sciencedirect.com. Available at:

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.