.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Lexie CornerMay 14 2024

By Susha Cheriyedath, M.Sc.Reviewed by Lexie CornerMay 14 2024In a paper published in Scientific Reports, researchers explored the use of modified chitosan in chemical flooding to enhance oil recovery in acidic reservoirs by combining chitosan with vinyl/silane monomers via emulsion polymerization.

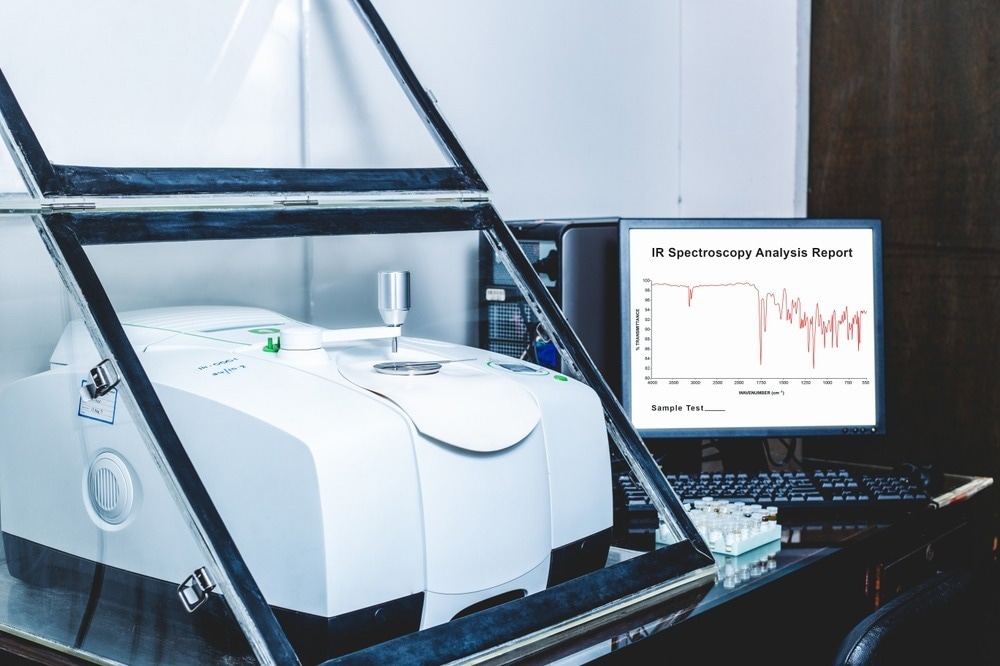

Image Credit: S. Singha/Shutterstock.com

Laboratory flooding experiments showed the modified composite's superior performance, with a significant viscosity increase and 11 % higher oil recovery than unmodified chitosan. Advanced simulations further validated its effectiveness, surpassing native chitosan and traditional water flooding methods.

Related Work

Previous studies have extensively explored the applications of chitosan, a biodegradable polysaccharide derived from chitin, in enhancing oil recovery (EOR) within the petroleum industry.

Chitosan's exceptional properties, including its solubility in acidic conditions and resilience to extreme environments such as high salinity and temperatures, have attracted significant interest.

Previous research has also investigated various aspects of chitosan's effectiveness, including viscosity enhancement and interfacial tension reduction.

Chitosan Composite Study

The study employed chitosan, a commercially sourced polysaccharide, along with various chemicals, including acrylamide, hexadecyltrimethylammonium bromide, triethoxyvinylsilane, acrylic acid, potassium persulfate, vinyl methacrylate, and acetic acid, all procured from Merck at analytical grade.

Chitosan powder was dissolved in pure acetic acid and mixed with synthetic brine under controlled conditions to ensure homogeneity, per American Petroleum Institute recommended practice 63 (API-RP-63) guidelines.

The team also prepared composite chitosan solution by dissolving chitosan powder in distilled water and adding a mixture of acrylamide, hexadecyltrimethylammonium bromide, acrylic acid, vinyl methacrylate, and triethoxyvinylsilane. The resulting solution underwent a thermal stabilization reaction, leading to the formation of the chitosan composite.

Incorporating or grafting vinyl monomers onto chitosan played a crucial role in enhancing the structural resistance of chitosan composites against salts and the hardness of formation water.

Core plug displacement experiments were conducted using core plugs obtained from the Bahariya formation in Egypt. The core plugs were cleaned, dried, and subjected to flooding experiments using synthetic brine, crude oil, and both native and composite chitosan solutions. Parameters such as absolute permeability, initial water saturation, oil permeability, original oil in place (OOIP), and residual oil saturation (Sor) were determined.

The data obtained from core flooding experiments, along with rheological data, were then incorporated into the tNavigator simulator to develop a reservoir-scale simulation model.

This model analyzed changes in water viscosity, mobility ratios, and other pertinent factors over time, providing insights into the performance of chitosan solutions in different reservoir conditions and well sites.

Chitosan Composite Analysis

The study characterized chitosan composites and their performance in core flooding experiments, followed by simulation modeling at laboratory and field scales.

Various analytical techniques, including Fourier transform infrared spectroscopy (FTIR), proton nuclear magnetic resonance spectroscopy (1H-NMR), and atomic force microscopy (AFM), were used to characterize the structural and surface properties of native and composite chitosan.

These analyses revealed significant differences in surface morphology and thermal stability between the two types of chitosan, indicating the successful incorporation of vinyl monomers and the enhancement of thermal stability in the composite.

The rheological behavior of native and composite chitosan solutions was investigated. Shear-thinning behavior and viscoelastic properties were shown. Composite chitosan exhibited higher resistance to changes in temperature and salinity compared to native chitosan, indicating its potential for improved performance in oil recovery operations.

Core flooding experiments showed that the chitosan composite outperformed native chitosan in terms of residual oil recovery and permeability reduction, highlighting its effectiveness in enhancing oil displacement and recovery.

Simulation modeling at both laboratory and field scales was carried out using the tNavigator simulator. The simulation results demonstrated good agreement with experimental data, confirming the efficacy of chitosan flooding in enhancing oil recovery.

Field-scale simulation results also showed that the composite chitosan achieved higher oil recovery than water flooding and native chitosan, indicating its potential for practical application in oil reservoirs.

Overall, the study provides comprehensive insights into chitosan composites' characterization, performance, and potential applications in oil recovery operations, highlighting its promising role in improving reservoir sweep efficiency and increasing oil recovery rates.

Conclusion

The modified chitosan with vinyl silylated monomers performed well in various tests. It showed remarkable tolerance to harsh conditions and increased viscosity when combined with silica nanoparticles. Both native and composite chitosan displayed shear-thinning behavior.

Core flood experiments demonstrated significantly higher additional oil recovery with composite chitosan than native chitosan. Field-scale evaluation further confirmed the enhanced performance of composite chitosan, particularly in acidic environments.

Journal Reference

Khattab, H., et al. (2024). Assessment of Modified Chitosan Composite in Acidic Reservoirs Through Pilot and Field-Scale Simulation Studies. Scientific Reports. https://www.nature.com/articles/s41598-024-60559-9.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.