In a paper recently published in the journal Materials, researchers analyzed the pozzolanic reaction and cementing properties of volcanic ash sourced from the Cumbre Vieja volcano and evaluated the replacement of cement as well as its impact on mortar production.

Study: Effect of Processed Volcanic Ash as Active Mineral Addition for Cement Manufacture. Image Credit: es3n/Shutterstock.com

Background

On September 19, 2021, the Cumbre Vieja volcano erupted, prompting the relocation of 7000 inhabitants, destroying over EUR 400 million of infrastructure, impacting 92.7 kilometers of roads and 1.212 hectares with solid ash and lava. All the volcanic solidified ash and lava, combined with a circular economy and increasing environmental awareness, mark the importance of studying the application of ash and lava in building materials, especially because the construction industry heavily contributes to environmental degradation, using 40% of the extracted raw materials.

Considering cement and its production process contribute substantially to climate change, accounting for 8% of total worldwide CO2 emissions, this study aimed to investigate utilizing the ash from the Cumbre Vieja volcano to replace cement in the manufacture of Portland cement, including its implications on mortar production.

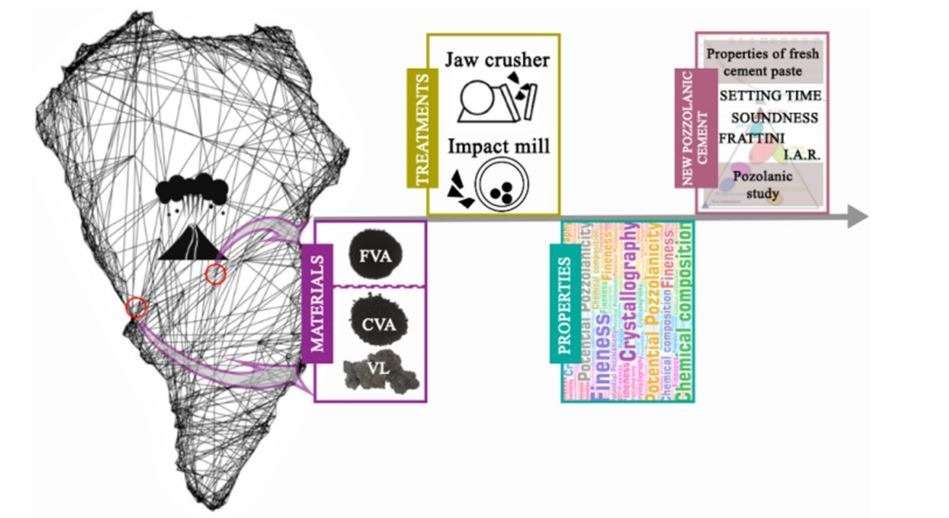

Experimental scheme. © Rosales, J.; Rosales, M.; Díaz-López, J.L.; Agrela, F.; Cabrera, M. (2022)

About the Study

In this study, the team studied volcanic material properties used for active mineral addition in cement manufacturing. Two powdered materials varying in fineness were obtained for each of the ash samples investigated, as well as a powdery material derived from volcanic lava. These were extracted from two locations on La Palma island, one close to the eruption (fine ash) and the other from the shoreline (volcanic lava and coarse ash).

The obtained materials underwent an advanced characterization analysis, emphasizing chemical composition, material fineness, pozzolanic activity, and crystallography. Furthermore, as a reference, two artificial pozzolanic components, which are frequently utilized in the cement industry, namely fly ash (FA) and silica fume (SF), were evaluated, together with limestone filler. With an average maintained size of about 20 microns, FA was the finest material examined.

To examine the effect of adopting volcanic material, an analysis of limestone filler for mineral addition was conducted. Their pozzolanic potential in comparison to SF and FA was assessed to establish their suitability for use in cementitious materials. The volcanic materials studied included two pyroclasts and one volcanic lava material. Moreover, X-ray diffraction (XRD) was used to investigate fine volcanic ash (FVA), coarse volcanic ash (CVA), and volcanic lava (VL).

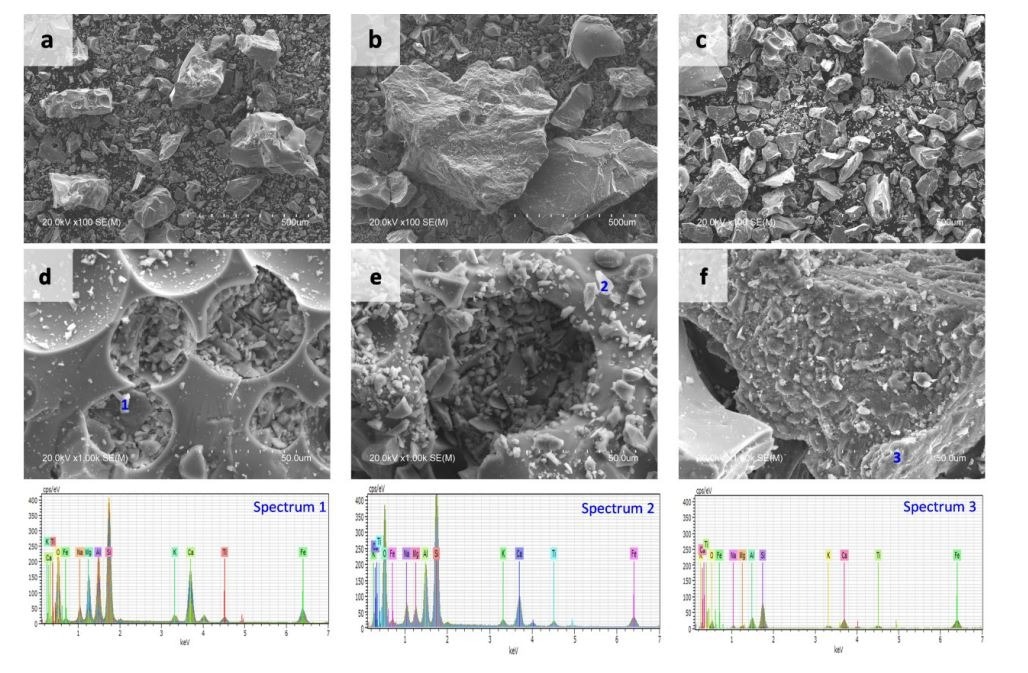

Scanning electron microscopy (SEM) was used to evaluate the volcanic material's morphology, and energy disruptive spectroscopy (EDX) was used to perform compositional analysis. Using the fixed lime technique, a preliminary investigation was conducted to assess the raw materials' pozzolanicity.

An accelerated approach was employed to quantify the progress of the material-lime reaction as a function of time. The material pozzolanicity was determined by immersing it in a saturated calcium oxide solution and measuring the absorption of calcium oxide by the sample. The cement paste was tested for volumetric expansion in accordance with EN 196-3.

Observations

When the calcium ion concentration in the analyzed mixture was less than the saturation concentration suggested by the reference curve, the mixture was regarded to be pozzolanic. All the ash mixtures tested were found to be above the curve.

The crushing of the volcanic ash improved the material's pozzolanic capacity. over a short period; the material was not deemed pozzolanic. However, the values were near the solubility curve. Crushing of the volcanic materials enhanced the pozzolanic characteristics of the mixtures to be used as supplementary cementitious materials.

Furthermore, compared to unprocessed volcanic ash, processed volcanic ash is more resistant. A substantial rise than the combination with LF was achieved, suggesting that they could be used in the production of cement as well as mineral additions in concrete.

Compared to the FA or the control mixture, the two samples prepared from processed volcanic ash had a more notable rise in resistance. This demonstrated that, compared to mixtures prepared with conventional cement, volcanic ash steadily increases its resistance with time. Including volcanic material lowers the cementitious pastes' volumetric expansion, and the setting time results for all volcanic materials were comparable.

As a result, the prepared mortars showed low dimensional differentiation at early curing ages because there was no occluded water or large pores within the mortars that would've altered the dimensions during early curing periods.

Conclusions

To conclude, the researchers determined that the mortars' compressive strengths produced with CVA and FVA rose significantly over time, outperforming the findings obtained with LF mixes. It is shown that crushed and unprocessed volcanic ash could be utilized as a natural pozzolan in cement production, surpassing mortars manufactured with limestone fillers. According to the authors, this study established the feasibility of the application of volcanic materials in cement production, indicating a promising, long-term supplemental cementitious material for use in cement manufacturing.

Reference

Rosales, J.; Rosales, M.; Díaz-López, J.L.; Agrela, F.; Cabrera, M. Effect of Processed Volcanic Ash as Active Mineral Addition for Cement Manufacture. Materials 2022, 15, 6305. DOI: https://www.mdpi.com/1996-1944/15/18/6305

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.