Plant-based alternatives to meat have grown in popularity over the past few years. To investigate the role of starch in meat analogs, a paper authored by scientists from The Netherlands has been published in the journal Polymers.

Study: Fibrous Structures from Starch and Gluten. Image Credit: badnews86dups/Shutterstock.com

The Growth of Fake Meats

Consumer patterns have changed in recent years as more people make the decision to switch to a plant-based or flexitarian diet for ethical, health, and environmental reasons. This trend is expected to continue in the future, and manufacturers in the food industry have developed a growing range of fake meat products which can meet the nutritional and diet demands of consumers.

The number of products available on the market is increasing every year. They provide critical nutritional needs such as protein for individuals who decide not to include meat in their diet. Importantly, these products must not only provide an alternative to animal products, but emulate the taste, textural, and visual characteristics of meat.

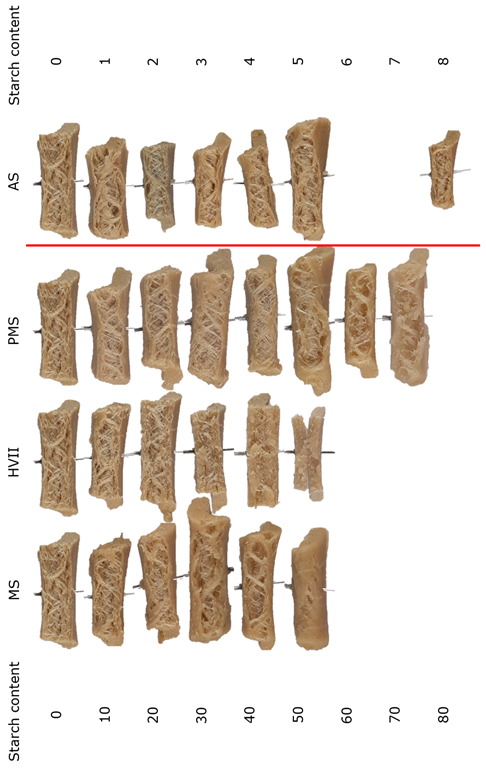

Photographs of the macro-structures after shearing MS, HVII, PMS, or AS in combination with gluten in the HTSC. Numbers in the left column indicate the amount of added starch (d.b.). The amount of added AS was 10-fold smaller, ranging over 1–8%. All samples had a dry matter content of 40% (w.b.). Each sample had a width of approximately 5 cm. Image Credit: Bühler, J.M/Shutterstock.com

Simulating Meat Fibers

The animal meat consumed worldwide is composed primarily of muscles, which have a complex, fibrous structure. Accurately simulating these fibers is a technically challenging process in the fake meat industry.

Fibers can be produced in plant-based meat analogs by various processes. Typically, these processes combine heat and shearing and can be produced using extruders and high-temperature shear cells. Protein-rich plant products are combined with water, and the underlying mechanisms of fiber formation are not completely understood currently.

The current consensus on how fibrous structures are created is that it is necessary to synthesize a multi-phase mixture that has specific properties. These properties have been extensively researched in recent years, along with the role of specific ingredients such as proteins and carbohydrates.

Understanding the Influence of Starch

The use of different plant-derived materials to produce fibers for meat analogs is a key research focus in the fake meat industry currently. Conventionally, fractionation/separation processes are used to purify protein-rich crops, which present sustainability challenges due to their intense use of water and energy resources.

Therefore, developing processes that use functional fractions could provide a route toward improved sustainability, which is at odds with the stated environmental benefits of reducing animal products in the human diet.

Research has focused on the use of starchy foodstuffs, especially pulses in meat analogs. Understanding the interactions between starch and other ingredients, such as protein, is crucial for their effective use in these composite food products.

Studies have investigated the influence of starch on product properties such as chewiness, hardness, and also fibrous physical properties. However, the exact mechanisms which govern the effect of starch have not been sufficiently explored in research.

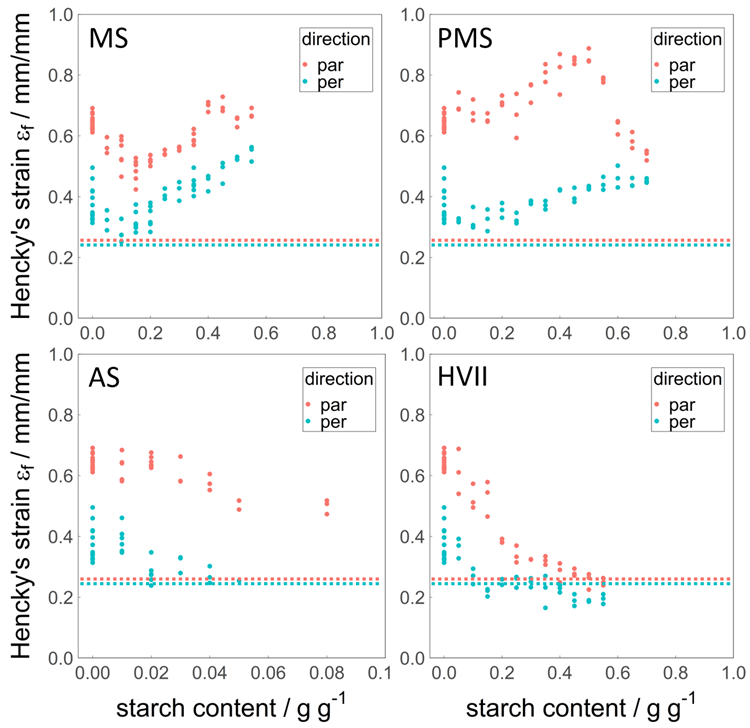

Fracture strain εf in parallel (red) and perpendicular (blue) directions over the added amount of MS, PMS, AS, and HVII (d.b.). The horizontal dotted lines represent the values for cooked chicken meat, data from Schreuders et al. Note that the x-axis for AS has a different range than the others (0–0.1 g g−1 instead of 0–1 g g−1). Image Credit: Bühler, J.M/Shutterstock.com

The Study

The study in Polymers aims to fill this critical research gap. Specifically, the study explores the role of starch in fiber formation in high-temperature shear cells. To the researcher’s knowledge, starch influence in high-temperature shear cells has not been explored in the current literature.

Emphasis has been placed on how product properties can be modified by the gelation behavior of starch and opportunities for optimizing meat analog fibrous structures. Three starch samples with differing amylose contents were investigated. The properties of these starches (low-amylose, intermediate-amylose, and high-amylose starch) have been extensively categorized in the current literature.

Amylose and amylopectin content significantly defines the functional properties of starch. By focusing on starches with different amylose content obtained from a single crop (maize,) influencing factors such as crop type have been discounted in the research. All samples of differing starch content were pre-gelatinized.

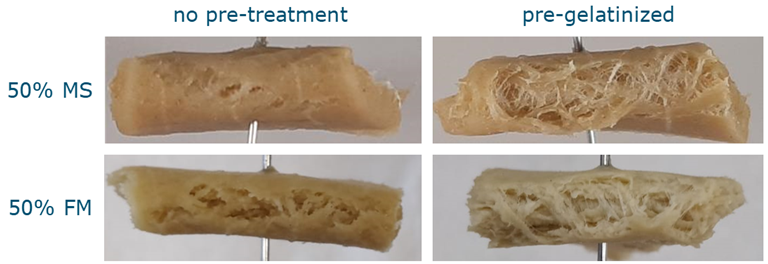

The prepared starch samples were evaluated with a recipe containing faba bean meal and gluten. Faba beans are low-fat and protein and starch-rich legumes which are used in a variety of cuisines worldwide. Faba beans were gelatinized and used in both their pre-treated and native conditions in the high-temperature shear cell.

By combining all the ingredients, the authors transferred the findings of the pure starch to less refined ingredients that can potentially be used to manufacture meat analogs. Faba beans were chosen due to the suitability of their isolated protein for forming fibrous structures in combination with gluten in high-temperature shear cells. Unrefined faba bean meal is insufficient for this process.

Photographs of the macrostructure after shearing gluten with untreated MS and FM, as well as pre-gelatinized MS and FM in the HTSC. All samples had a dry matter content of 40% (w.b.), with a gluten content of 50% (d.b.). Each sample has a width of approximately 5 cm. Image Credit: Bühler, J.M/Shutterstock.com

The authors demonstrated that substantial amounts of starch can be added to gluten to form fibrous structures. Moreover, unique textural characteristics can be incorporated into fake meats depending on the amount and type of starch used. Different technological properties were produced such as water uptake and viscosity depending on the different amylose and amylopectin contents of starches.

By pre-gelatinizing the starch, fibrous product formation was enhanced and led to increased Young’s modulus anisotropy, producing a product analogous to chicken meat. Gluten network density improves with increased strength due to higher water uptake at room temperature. The research has demonstrated that starch can help to produce more accurate meat analogs, and in-situ modification of starch-rich crops is suitable for producing fake meats with fibrous structures.

Further Reading

Bühler, J.M, Van der Goot, A.J & Bruins, M.E (2022) Fibrous Structures from Starch and Gluten Polymers 14(18) 3818 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/18/3818.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.